Stainless steel submersible pumps have gained significant popularity across various industries due to their unparalleled durability and efficiency.

These pumps are particularly valuable in applications where reliable water management is crucial.

Understanding the benefits and features of these pumps can empower you to make an informed choice that meets your specific water management needs, whether for residential, agricultural, or industrial purposes.

What are the Key Features of Stainless Steel Submersible Pumps?

Durable Material

The primary material used in stainless steel submersible pumps is stainless steel, known for its exceptional resistance to corrosion and rust.

This characteristic is particularly important in environments where water can be contaminated with minerals and other corrosive substances.

As a result, pumps made from stainless steel enjoy a longer lifespan, reducing the need for frequent replacements and contributing to lower overall operational costs.

High Efficiency

Stainless steel submersible pumps are engineered to operate with high efficiency, ensuring optimal performance while consuming minimal energy.

This efficiency not only translates to lower electricity bills but also means that the pumps can handle large volumes of water with ease.

Advanced design features allow these pumps to maintain high flow rates while minimizing wear and tear, which is essential for long-term performance.

Versatile Applications

These pumps are remarkably versatile and can be utilized in a wide range of settings.

From residential applications, such as draining flooded basements, to agricultural uses like irrigation, and even industrial scenarios where large water volumes need to be managed, stainless steel submersible pumps are up to the task.

Their adaptability makes them a preferred choice among professionals across various sectors.

Easy Maintenance

One of the standout advantages of stainless steel submersible pumps is their ease of maintenance.

Unlike pumps made from other materials, stainless steel pumps typically require less frequent servicing, which can save both time and money.

Their robust construction means they can withstand harsh conditions, reducing the likelihood of breakdowns and the associated costs of repairs.

And More:

- Are Stainless Steel Submersible Pumps More Expensive?

- Best Submersible Pumps for Waterworks: Top Models, Features, and Buying Guide 2024

How Do Stainless Steel Submersible Pumps Work?

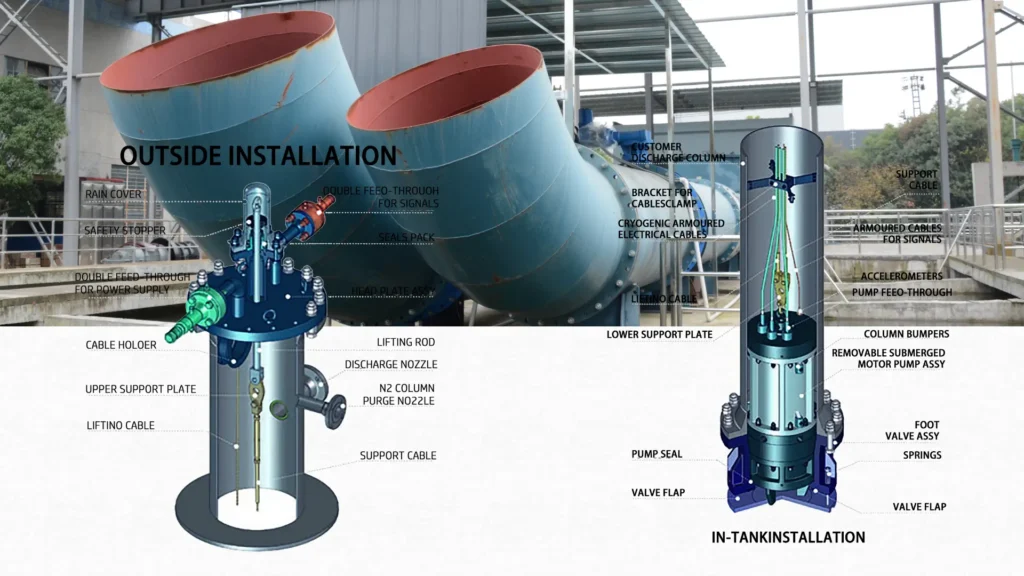

Basic Operation

Stainless steel submersible pumps function by converting electrical energy into mechanical energy, which is then used to move water efficiently.

This process involves a motor that drives the pump’s impeller, creating the necessary force to push water through the system.

The design of these pumps ensures that they can operate effectively even in deep water conditions, making them ideal for various applications.

Submersion Principle

The principle of submersion is crucial to the operation of these pumps, as being submerged in water allows for efficient cooling of the motor.

This cooling effect prevents overheating during extended use, enhancing the reliability of the pump.

Being submerged reduces the risk of cavitation, a phenomenon that can damage pumps and lead to decreased performance.

Impeller Function

The design of the impeller plays a vital role in the functionality of stainless steel submersible pumps.

The impeller creates a pressure differential that effectively pushes water through the pump system.

This design not only facilitates the movement of water but also enhances the pump’s overall efficiency, allowing it to handle varying flow rates and pressures with ease.

Electrical Components

High-quality electrical components are essential for the reliability and performance of stainless steel submersible pumps.

These components are engineered to withstand demanding conditions, ensuring that the pump operates smoothly and efficiently.

The integration of advanced technology in the electrical system enhances the pump’s overall functionality, providing users with confidence in its performance over time.

What are the Benefits of Using Stainless Steel?

Corrosion Resistance

Stainless steel is renowned for its natural resistance to corrosion, making it an excellent choice for various water applications.

This property ensures that stainless steel components can withstand exposure to moisture and harsh chemicals without degrading over time.

The ability to resist rust and corrosion means that equipment made from stainless steel can maintain its structural integrity and performance, even in challenging environments, ultimately extending its lifespan and reducing maintenance costs.

Strength and Durability

The strength and durability of stainless steel are significant advantages in many applications.

This material can endure harsh conditions, including extreme temperatures and pressures, without compromising its performance.

Its robust nature makes stainless steel suitable for both indoor and outdoor use, ensuring reliability in environments where other materials might fail.

The long-lasting nature of stainless steel means fewer replacements and repairs, thereby enhancing overall operational efficiency.

Hygiene and Safety

Stainless steel is a non-toxic material that is easy to clean, which is particularly important for applications involving potable water.

Its smooth surface inhibits the growth of bacteria and other pathogens, ensuring that water remains safe for consumption.

The hygiene factor of stainless steel is crucial in many industries, including food and beverage, healthcare, and water treatment, where maintaining cleanliness and safety standards is a top priority.

Environmental Impact

Using stainless steel pumps has a positive impact on the environment, primarily due to their longevity.

The durability of stainless steel reduces the need for frequent replacements, which minimizes waste and the environmental footprint associated with manufacturing and disposing of pumps.

The energy efficiency of stainless steel pumps contributes to lower energy consumption, further enhancing their eco-friendly profile.

Also Read:

- Comparison Between Steel and Cast Iron Submersible Pumps

- What is the Process For Cleaning a Stainless Steel Submersible Pump?

Where Can You Use Stainless Steel Submersible Pumps?

Residential Uses

Stainless steel submersible pumps are exceptionally well-suited for various residential applications.

They can effectively drain flooded basements and swimming pools, ensuring that these spaces remain safe and dry.

These pumps are ideal for irrigation systems, providing efficient water delivery to gardens and lawns, helping homeowners maintain aesthetically pleasing outdoor spaces.

Agricultural Applications

In the agricultural sector, stainless steel submersible pumps play a vital role in irrigation and water supply management.

Farmers rely on these pumps to deliver water efficiently to crops, ensuring optimal growth and yield.

Their durability and efficiency make them indispensable for managing water resources effectively, particularly in regions where water scarcity is a concern.

Industrial Settings

Industries frequently utilize stainless steel submersible pumps for various purposes, including wastewater management and industrial processes.

These pumps are capable of handling challenging materials and conditions, making them ideal for environments where reliability is essential.

Their corrosion-resistant properties ensure that they can operate effectively in harsh industrial settings, contributing to streamlined operations and reduced downtime.

Construction Sites

Stainless steel pumps are invaluable on construction sites, where they assist in dewatering and maintaining site safety.

These pumps help remove excess water from excavations and foundations, preventing delays and ensuring that construction work can proceed smoothly.

Their robustness and reliability under demanding conditions make them a preferred choice for contractors seeking to maintain efficiency and safety on their job sites.

How Do They Compare to Other Pump Types?

Plastic vs. Stainless Steel

Plastic pumps may initially appear to be a more economical choice due to their lower purchase price.

However, they often lack the durability and efficiency that stainless steel pumps offer.

While plastic is lightweight and resistant to some chemicals, it is not as robust as stainless steel, making it more susceptible to damage and wear over time.

This can lead to higher long-term costs due to replacements and reduced operational efficiency.

Stainless steel pumps provide reliable performance in various conditions, making them a more cost-effective option in the long run.

Cast Iron Alternatives

Cast iron pumps are known for their strength and durability, making them a common choice in heavy-duty applications.

However, they have notable downsides, including a tendency to rust when exposed to moisture.

This susceptibility to corrosion can lead to increased maintenance requirements and potential failures, impacting overall efficiency.

In comparison, stainless steel pumps provide a rust-resistant solution that requires less frequent upkeep, ensuring consistent performance without the risk of degradation associated with cast iron.

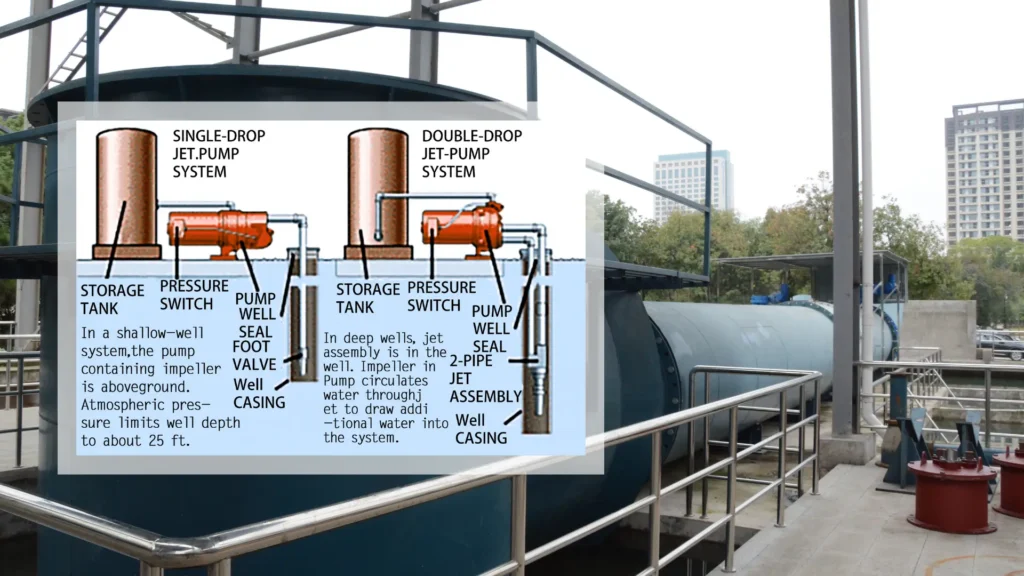

Submersible vs. Surface Pumps

When comparing submersible pumps to surface pumps, it becomes clear that submersible pumps are typically more efficient for extracting water from deeper sources.

Submersible pumps operate underwater, which allows them to exert pressure directly at the source, minimizing energy loss and improving overall efficiency.

Surface pumps, while useful for shallower applications, often struggle to draw water from significant depths, requiring more energy and resulting in lower efficiency.

This distinction makes submersible pumps the preferred choice for applications involving deep wells or underground water sources.

And More:

- Cost Comparison: Submersible Pumps from China vs Other Countries

- How to Evaluate and Select a Configuration of Multiple Pumps

What Should You Consider When Purchasing?

Size and Capacity

Evaluating the pump’s size and capacity is crucial to ensure it meets specific needs effectively.

Each application has unique requirements regarding the volume of water to be moved and the height it needs to be lifted.

Selecting a pump that matches these specifications will enhance efficiency and prevent issues related to overworking the pump, which can lead to premature failure.

A thorough assessment of your water management needs will help determine the appropriate size and capacity for optimal performance.

Energy Efficiency

Energy efficiency is an essential factor to consider when purchasing a pump, as it directly affects operating costs.

Opting for energy-efficient models can lead to significant savings over time, especially in applications with continuous or high-volume water movement.

Pumps designed with energy efficiency in mind often utilize advanced technology and materials that reduce power consumption while maintaining performance.

Evaluating the energy ratings and operational efficiency of various models will help in making a cost-effective choice.

Brand Reputation

Choosing pumps from reputable brands is essential for ensuring quality and reliability.

Established manufacturers often have a proven track record of producing durable and efficient products, backed by customer testimonials and industry reviews.

Investing in a pump from a trusted brand not only increases the likelihood of satisfactory performance but also provides peace of mind regarding customer support and service options.

Researching brand reputation can help guide your purchasing decision toward the most reliable options available.

Warranty and Support

Considering the warranty and customer support offered by the manufacturer is critical when purchasing a pump.

A robust warranty can provide assurance of quality and protect your investment, covering potential defects or issues that may arise.

Effective customer support can be invaluable if you encounter problems or have questions about installation and operation.

Ensuring that the manufacturer offers comprehensive warranty terms and readily available support can greatly enhance your overall satisfaction with the product.

Conclusion

Choosing a stainless steel submersible pump can significantly enhance your water management solutions.

With their exceptional durability, efficiency, and versatility, these pumps are a smart investment for a wide range of applications.

Understanding their features and benefits, along with comparing them to other pump types, will guide you in making the best choice tailored to your specific needs.

Investing in a quality pump not only improves performance but also contributes to long-term cost savings and reliability in water management.