In an era of rapid technological advancement, the integration of smart technologies into various industries has become a game – changer.

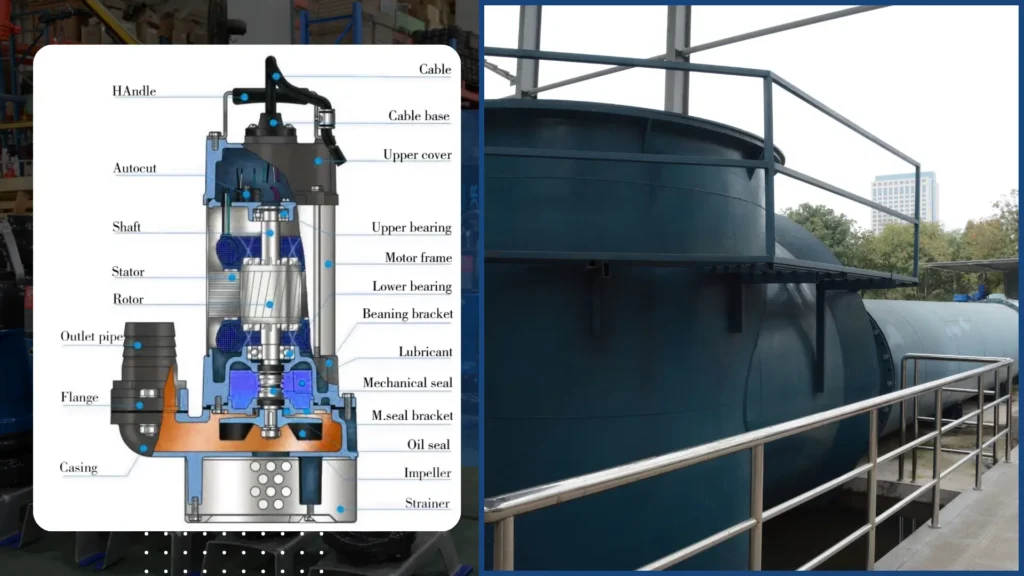

Submersible pump systems, crucial for fluid management in numerous sectors, are no exception. Implementing smart technologies can enhance the performance, efficiency, and reliability of these systems.

This article aims to guide potential buyers on how to incorporate smart technologies into submersible pump systems, offering practical insights and benefits in an easy – to – understand manner.

Why Should You Implement Smart Technologies in Submersible Pump Systems?

Improved Operational Efficiency

Smart technologies enable real – time monitoring and optimization of submersible pump operations.

This eliminates unnecessary energy waste and ensures the pump operates at its most efficient point, reducing operational costs in the long run.

Enhanced System Reliability

With smart sensors and predictive maintenance capabilities, potential issues in submersible pump systems can be detected well in advance.

Instead of reacting to breakdowns, operators can proactively address problems, minimizing downtime.

This not only protects the investment in the pump system but also ensures continuous fluid supply, which is vital for industries that rely on these pumps.

Remote Monitoring and Control

Smart technologies allow for remote access to submersible pump systems.

Operators can monitor the pump’s status, adjust settings, and receive alerts from anywhere with an internet connection.

This flexibility is especially valuable for pumps installed in remote locations or hard – to – reach areas, as it reduces the need for on – site inspections and manual adjustments, saving time and labor costs.

How Can You Start with Sensor Installation?

Selecting the Right Sensors

The first step in implementing smart technologies is choosing the appropriate sensors.

Flow sensors can measure the volume of fluid pumped, pressure sensors monitor the pressure within the system, and temperature sensors detect overheating.

For submersible pumps, sensors with high – quality waterproof and corrosion – resistant materials should be selected to withstand the harsh underwater environment.

Installing Sensors Correctly

Proper sensor installation is crucial for accurate data collection. Sensors should be placed at key points in the pump system, such as near the impeller, at the inlet and outlet, and on the motor.

Follow the manufacturer’s instructions carefully during installation to ensure the sensors are securely attached and calibrated correctly.

Incorrect installation can lead to inaccurate data and ineffective monitoring.

Connecting Sensors to the Monitoring System

After installation, sensors need to be connected to a central monitoring system. This can be done through wired or wireless connections, depending on the system’s design.

Wired connections offer stable data transmission but may require more complex installation, while wireless connections provide greater flexibility but need to consider signal strength and interference issues.

Ensure a reliable connection to enable seamless data flow from the sensors to the monitoring platform.

What Are the Steps for Implementing Remote Monitoring?

Choosing a Remote Monitoring Platform

There are various remote monitoring platforms available in the market. Look for platforms that are user – friendly, offer real – time data visualization, and have robust security features.

Some platforms also provide analytics tools to help interpret the data collected from the submersible pump system.

Consider the specific needs of your operation, such as the number of pumps to be monitored and the level of detail required, when selecting a platform.

Opt for platforms that support easy integration with existing pump hardware to avoid compatibility issues during setup.

Setting Up the Network Infrastructure

To enable remote monitoring, a reliable network infrastructure is essential.

For pumps in remote areas, cellular or satellite communication may be necessary. Install routers, modems, and other network devices as required and ensure proper configuration.

Test the network connection thoroughly to ensure stable data transfer between the pump system and the remote monitoring platform.

Incorporate backup network solutions, such as secondary cellular plans, to prevent data loss during primary network outages.

Regularly update network firmware and security protocols to safeguard against potential cyber threats and maintain optimal performance.

Training Operators on Remote Monitoring

Once the system is set up, train your operators on how to use the remote monitoring platform effectively.

Teach them how to access data, interpret the information, and respond to alerts. Familiarize them with the different functions and features of the platform, such as adjusting pump settings remotely and generating reports.

Well – trained operators can make the most of the remote monitoring capabilities and ensure the smooth operation of the submersible pump system.

Develop a training manual that outlines step – by – step procedures for common tasks and troubleshooting scenarios to serve as a quick reference.

Schedule periodic refresher sessions to keep operators updated on platform updates or new features, ensuring their skills remain relevant over time.

How Can You Utilize Predictive Maintenance Technologies?

Analyzing Historical Data

Predictive maintenance relies on analyzing historical data from the submersible pump system.

Collect data on factors like motor performance, vibration levels, and electrical parameters over time.

Use data analytics tools to identify patterns and trends.

Implementing Machine Learning Algorithms

Machine learning algorithms can enhance the accuracy of predictive maintenance.

These algorithms can continuously learn from new data and improve their prediction models.

They can detect subtle changes in the pump’s operation that may not be easily noticeable through manual analysis. Integrate machine – learning – based predictive maintenance software into your system to automatically generate maintenance schedules and alerts based on the predicted failure probabilities.

Creating a Maintenance Plan

Based on the predictions from the data analysis and machine learning algorithms, create a comprehensive maintenance plan.

Prioritize maintenance tasks according to the urgency and potential impact on the pump’s operation. Include details such as the type of maintenance, the required spare parts, and the estimated time for completion.

A well – structured maintenance plan helps ensure that maintenance activities are carried out in a timely manner, preventing unexpected breakdowns.

How Do Variable Frequency Drives (VFDs) Fit into Smart Pump Systems?

Understanding the Function of VFDs

Variable Frequency Drives (VFDs) are key components in smart submersible pump systems.

They control the speed of the pump motor by adjusting the electrical frequency supplied to it.

This allows the pump to operate at different speeds according to the actual fluid demand.

Installing and Configuring VFDs

When installing VFDs, follow the manufacturer’s guidelines carefully. Ensure proper electrical connections and select the right – sized VFD for your pump motor.

After installation, configure the VFD settings based on the pump’s operating requirements and the expected range of fluid demand.

Set parameters such as the minimum and maximum speed, acceleration and deceleration rates, and the control mode (e.g., manual or automatic).

Integrating VFDs with the Monitoring System

To fully utilize the capabilities of VFDs in a smart pump system, integrate them with the central monitoring system.

This integration allows for real – time adjustment of the VFD settings based on the data collected from sensors.

This seamless integration optimizes the pump’s performance and energy consumption.

How Can Energy Management Systems Optimize Pump Operations?

Measuring Energy Consumption

The first step in energy management is accurately measuring the energy consumption of the submersible pump system.

Install energy meters at key points in the electrical circuit to monitor the power usage of the pump motor, VFD, and other components.

Analyze the energy consumption data over time to understand the patterns and identify areas for improvement.

Implementing Energy – Saving Strategies

Based on the energy consumption analysis, implement energy – saving strategies.

This can include adjusting the pump’s operating schedule to match the peak and off – peak energy demand periods, optimizing the VFD settings for maximum efficiency, and using energy – efficient components.

Monitoring and Evaluating Energy Savings

Continuously monitor the energy consumption of the pump system after implementing the energy – saving strategies.

Compare the actual energy usage with the baseline data to evaluate the effectiveness of the measures.

Use the monitoring results to make further adjustments and improvements to the energy management plan, ensuring that the submersible pump system operates as efficiently as possible in terms of energy consumption.

How to Ensure Cybersecurity in Smart Pump Systems?

Identifying Potential Cybersecurity Risks

Smart submersible pump systems are vulnerable to cybersecurity threats, such as unauthorized access, data breaches, and malware attacks.

Identify the potential entry points for these threats, such as the network connections, remote monitoring platforms, and sensor interfaces.

Understand the types of data that are at risk, including operational data, sensor readings, and control commands.

Implementing Security Measures

To protect the system from cybersecurity risks, implement a range of security measures.

This includes using strong passwords, encrypting data transmissions, and regularly updating the software and firmware of the monitoring system and other components.

Install firewalls and intrusion detection systems to prevent unauthorized access to the system.

Also, limit the access rights of operators and ensure proper user authentication and authorization.

Conducting Regular Security Audits

Regularly conduct security audits of the smart pump system to assess its vulnerability to threats.

Check for any security loopholes or weaknesses in the system’s design, implementation, and operation.

Update the security measures based on the audit results and the latest cybersecurity best practices.

Conclusion

Implementing smart technologies in submersible pump systems offers numerous benefits, from improved efficiency and reliability to enhanced remote management and energy savings.

Whether it’s through sensor installation, remote monitoring, predictive maintenance, or other smart solutions, these technologies can transform the way submersible pumps operate, providing long – term value and competitive advantages in various industries.

As industries continue to prioritize sustainability and operational agility, integrating such smart features will become increasingly critical for staying ahead in a rapidly evolving technological landscape.

Moreover, the initial investment in these technologies is often offset by reduced downtime, lower maintenance costs, and optimized resource usage over time.

And More: