The material used in construction of submersible pumps significantly impacts the performance, lifetime, and cost effectiveness of the pump.

Proper selection of material is vital for ensuring the pump withstands the environmental settings it will function.

Beside corrosion resistance, factor such as weight and durability also have to be pondered for smooth and long-lasting working.

Therefore, understanding the perspective of the material selection helps a customer to deal with smarter choices conformed to the needs of his operations.

The two most common construction materials used in the manufacture of these pumps are steel and cast iron, each having their own unique properties, which are considered suitable for specific applications.

For instance, steel is beautifully strong and versatile while cast iron is the less expensive and more wear-resistant material.

Therefore, understanding the application of these materials helps a customer choose the best solution under his specific conditions and requirement.

And More:

- Material Selection for Durable Submersible Pumps in Large-Scale Waterworks

- Understanding Industrial Submersible Pumps: Definition, Advantages, and Types

Properties of Steel Submersible Pumps

Strength and Durability

Submersible pumps made from steel are famous for being robust and durable.

They can tolerate high pressure as well as severe loading without bending, which are perfect for harsh environments like mining and for well deep pumping.

It is not an easy material with which to work. Steel pumps are also more resistant to wear and tear and keeping them working perfectly for much longer in extreme conditions.

As durability is kept, the costs are also kept at a minimum, thus moneysparing for businesses.

Corrosion Resistance

The main problem with a steel pump is the fact such a material can be suffered from types of corrosion, especially in severe or acid solutions.

Nevertheless, new coatings like galvanizing or epoxy coatings has improved the material from the outside with respect to tolerating chemicals.

It has thus become possible for steel to do well with various adverse mediums. If the steel pump is maintained well, it also will provide prolonged service and eliminate the possibility of regular replacement.

Weight Consideration

Usually the weight of steel pumps is heavier than that of cast iron pumps, compromising handling and installation, with the additional expenditure ensuring more solid mounting systems so that transportation would be enhanced and largely to be avoided.

The higher weight of steel is advantageous in terms of strength but the heaviness needs to be taken into account by the potential buyers with reference to their specific installation and operational processes.

Properties of Cast IronSubmersible Pumps

Cost-Effective

Cast iron submersible pumps are often cheaper than their steel counterparts. They prove to be an affordable option for budget-sensitive buyers.

This cost advantage is particularly useful for projects that require a lot of cost cutting or those applications where the performance is not highly critical.

Thus, by opting for cast iron, users can have reliable functioning without any adverse effect on quality, making this the choice of many modern industrial applications.

Great Ability to Withstand Wear

Possessing an excellent wear resistance should be known well by cast iron where abrasives come into play.

This helps cast iron wherein, solid particles in the stream can get past the pump parts without any significant wear, henceforth increasing life service capacity.

Because casts iron pumps are tough against abrasion, they get accepted applications that require pumping wastewater and other locations where lots of particulate matter can be observed.

Cast Iron’s Best: Heat Conductivity

A cast iron is better suited to dissipate heat that overheats in the pump’s operation.

In hot liquid conditions, for example, its thermal conductivity is of exceptional benefit as it helps to keep the temperature optimal and to prevent overheating.

Low heat could even make a cast iron pump emit well: its operation gets good results as far as energy conservation is affected.

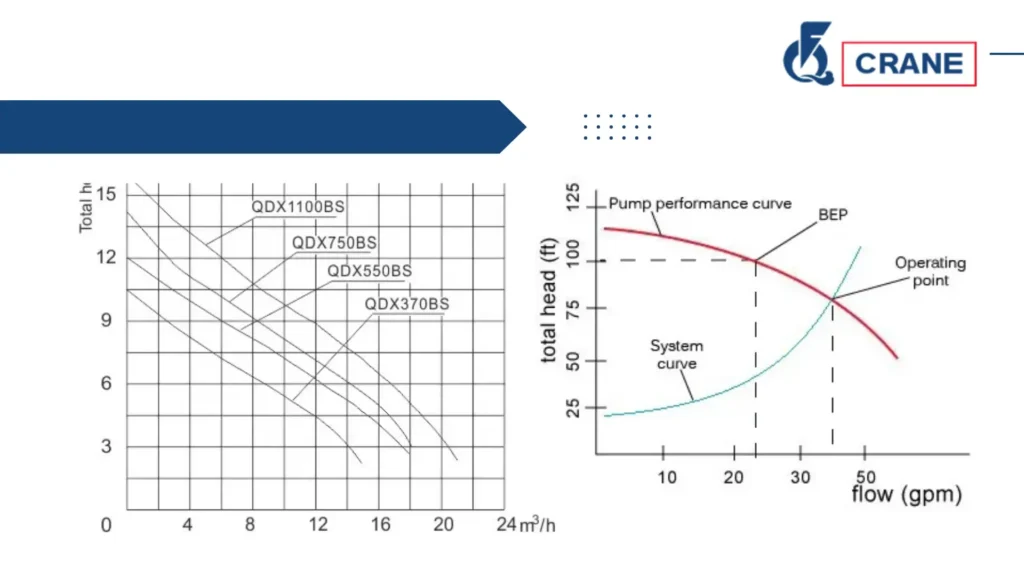

Performance Comparison

Corrosion

Often, steel pumps offer a fair contrast to cast iron pumps in these areas.

Their higher-strength features and special design packages usually make them a better choice for high-pressure applications; furthermore, they are known to sustain performance in very demanding circumstances, such as in applications that need deep-well pumping and industrial uses.

On the other hand, cast iron pumps often lack the efficiency needed for such an environment, so their capacity will thus be diminished partly to allow their strength limits.

Flow

In a normal pump regime, one of the most important requirements when choosing it for specific tasks would be flow requirements.

Often, steel submersible pumps offer bigger flow rates than cast iron ones do because of their significant differences in construction and engine.

They can handle a high amount of liquid because they are able to move larger fluid volumes, and hence, industrial uses of such pumps, like pumps for large-scale irrigation or for rapid working fluid movement, become joggingly possible.

Cost of Maintenance

Maintenance is a fundamental consideration for all types of pumps. Steel pump systems can be expected to suffer more through maintenance, mostly from corrosion that affects them so dreadfully, especially in a bad environment.

Regular check-ups and preventive maintenance can, however, help control any problems related to corrosion.

On the contrary, cast iron pumps do not need much worry mostly because they can withstand leaving behind very slightly abrasive conditions.

With less maintenance, operational downtime is also reduced, improving production time.

Applications of Steel Submersible Pumps

Industrial Use

There is a great need for steel submersible pumps in the industrial sector.

Normally, they are used in several mining, construction, or oil extraction works: everything that concerns very heavy maintenance work, where high efficiency and reliability is the basic necessity.

It is widely the case that steel pumped material is fit for high pressure, handling such a heavy load, which is frequently the case in steel submersible pumps.

High-Pressure Environments

These pumps are rated high at sustaining high pressure and are an effective option for use in applications such as deep-well pumping.

These applications are actually very difficult and tough to handle, unlike the conventional steel submersible pumps.

Generally, these types of steel pumps can bear all conditions and hence are considered to be perfect for deep waters.

Chemical Handling

The analysis for safe handling of chemicals in factories, which involve a specialization of materials selected due to the need of specific compounds, is of particular interest here.

Steel submersible pumps can be used for special materials specifically selected by these clients despite the fact that the coating of such materials may vary in forming the pump of acid-proof metal.

Applications of Cast Iron Submersible Pumps

Water Treatment

Solid waste and abrasive materials can be handled by cast iron submersible pumps.

They are advantageous for wide use in wastewater treatment systems especially in industries.

They are unique in that they are durable and cost-effective for municipal application where reliability is very important.

They are excellent sewage pumps, meaning they can effectively and efficiently manage sewage and other wastewater streams in the process of effective treatment and disposal.

Agricultural Applications

It is commonly used for irrigation and drainage in agriculture, where the task of submersible cast iron pumps is taking place.

However, it is known for its reliability in terms of water pumping and what makes such pumps very famous to the farmers and agricultural businesses.

It provides excellent performance continuously so that a few of the operations serve for the result when affecting effluent.

Residential Uses

Domestically, cast iron pumps are generally used for pie-hole and sewage applications. They are affordable and effectively handle a runlet.

These pumps provide a direct solution for the household drainage needs and are common in almost all house plumbing systems for being interposed in them.

Pros and Cons of Steel Submersible Pumps

Advantages

Highly Durable and Strong

They have a high strength that makes them desired for operations under high pressure and heavy loads.

Perfectly Fit for High Pressure Operations

The build of the pipe defines that withstanding of high efforts is realized through their shape.

Approved for Usage in Many Applications

They are attributed to having cases that have historically had aggressive media, with the use of special paints.

Disadvantages

Corrosion Safety Is Lower

It will immediately result in significant damages to the substance, including corrosion within the product due to various weather conditions.

Heavily Loaded during Installation

The heavier weight of steel pumps further complicates fitting, especially for deep applications of water.

High Amount of Maintenance Needed

There is an increased need for maintenance to be performed regularly, while the operation is not each time this is executed.

Pros and Cons of Cast Iron Submersible Pumps

Advantages

Expensive Services for All Purposes

Iron casting pumps are generally cheaper and thus feasible to projects constrained by budget.

Wear Facts Particularly in Abrasive Environments

Its durability level in abrasive environments could even portray extended operating periods and fewer maintenance solutions.

Lesser Maintenance Intervals Because of Longevity

The use of an iron cast pump generally requires less frequent checks, thus guaranteeing greater sense of effectiveness and decreased downtime.

Disadvantages

Generally Weak So It Can’t Hold Much Pressure

Generally speaking, cast iron would be less efficient for high pressure environments and thus have less applications for high-powered duties.

Strength Limitations in Extreme Pressure Situations

The tensile limitation of cast iron causes inferior performance under high pressures.

Heavyer Than Few Others, Affecting Portability

Cast-iron pumps tend to be heavy, which may affect effectiveness when it comes to handling the machinery on-the-go.

Making an Informed Decision

Assessing Your Needs

When it comes to making a choice between steel or cast-iron submersible pumps, you need to consider your needs.

Consider the type of fluid being moved, the operating environments and the budget constraints.

Knowing such helps you in decision making on the best pump for your particular application.

Consultation with Professionals

It’s good to get professionals opinion; they can guide you on the best material to go for.

They can always look into your issue, analyze it, and come out with relevant options.

They can guide you through the complexity of the pump selection process and provide much better return in the selection of a pump.

Evaluating long-term Costs

Financial implications aside, what will be significant in the long term is an assessment of total ownership costs, including maintenance costs, increased operational efficiency, and maintenance costs among other factors.

To cite an example, even if the cost difference between the two pumps is small upon initial setup, the payback amount will be addressed at a later funding stage since the operational application of these two pumps will be clearly seen.

Conclusion

These submersible pumps have very unique advantages as well as disadvantages which come about if they are made of steel or cast iron.

Its strength and efficiency superiority makes steel pumps the best option more so for heavy applications while cast iron pumps offer a cheaper version with good wear performance if the application is light enough not to wear the casing.

Knowing scope between them is important for a good purchase decision.

The ultimate decision of the proper pump choice for either steel or cast iron could essentially be according to the specific requirements of the application, budget considerations, and long-term expectations for performance.

By taking your time to recognize your needs and discussing with professionals, a well-informed choice can be made in all matters of basic building operational synergy and reliability to gain an upper hand in pumping.

Ultimately, the right investments will result in increased production values and decreased operational expenditure in the long run.