In the world of agricultural irrigation, having a reliable and efficient way to move water is crucial for the growth and productivity of crops.

Submersible pumps have become an integral part of many farming operations, quietly working beneath the water to ensure that fields get the right amount of moisture.

This article aims to shed light on these useful devices, explaining their role in simple terms so that those considering purchasing one can better understand their benefits and how they fit into agricultural irrigation setups.

How Do Submersible Pumps Work in Agricultural Irrigation?

Design and Positioning of Submersible Pumps in Agricultural Irrigation

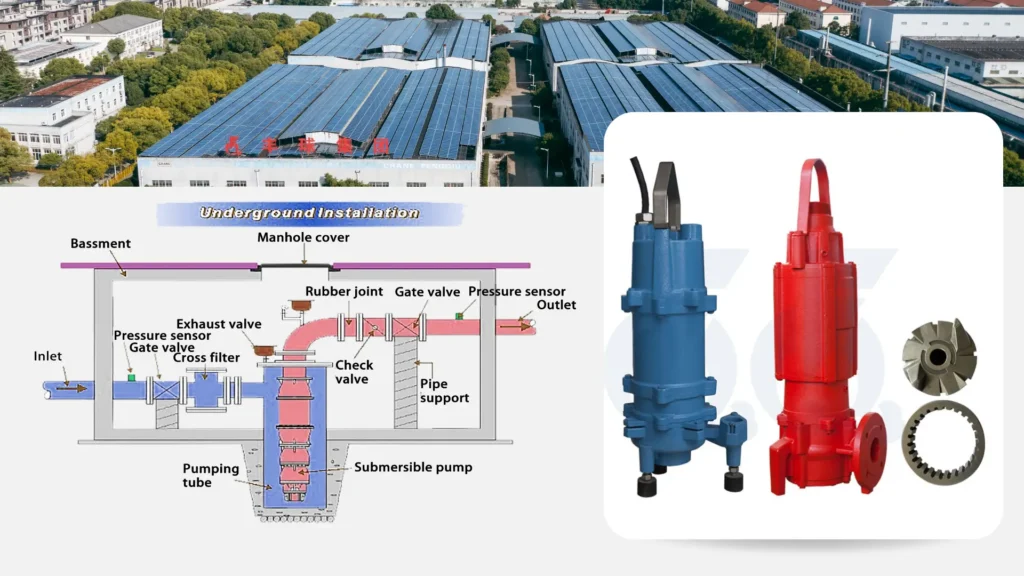

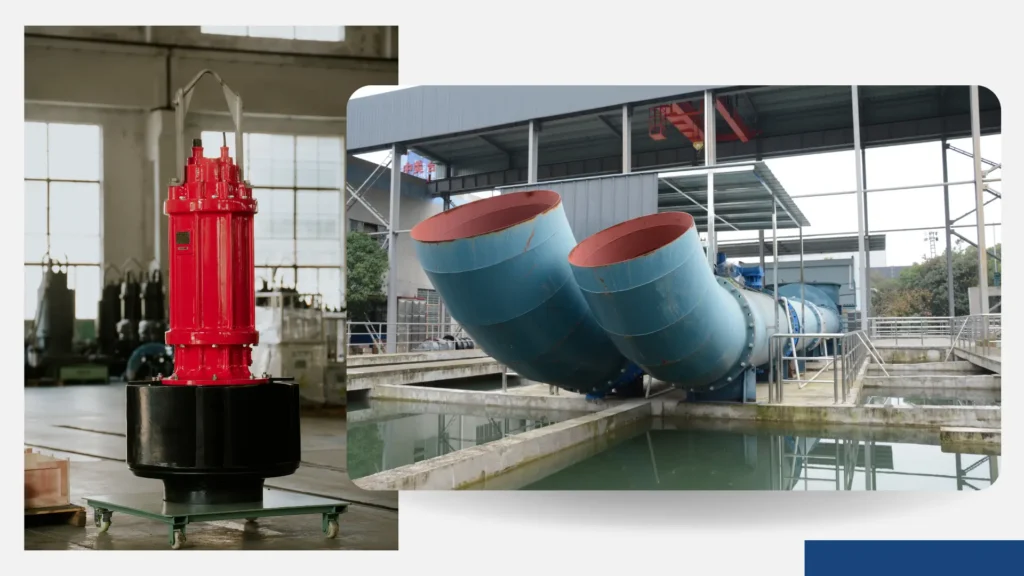

Submersible pumps are engineered to function entirely underwater, a design that sets them apart from above-ground pumps in agricultural irrigation.

Instead of being positioned on the surface and relying on suction to draw water upward, these pumps are directly immersed in the water source—whether it’s a deep well, a large pond, a reservoir, or even a natural stream.

This submersion eliminates the need for complex suction mechanisms, as the pump is already surrounded by water, allowing it to initiate water extraction with minimal effort.

Hermetically Sealed Design: A Critical Feature

A key feature is their integrated, hermetically sealed design: the motor and pump components are fused into a single unit, encased in a waterproof housing.

This tight seal is critical—it prevents water from seeping into the motor, which could cause short circuits, corrosion, or mechanical failure.

Even when submerged for extended periods, this design ensures the motor remains dry and operational, reducing the risk of system downtime.

Core Mechanism: Using Centrifugal Force for Water Movement

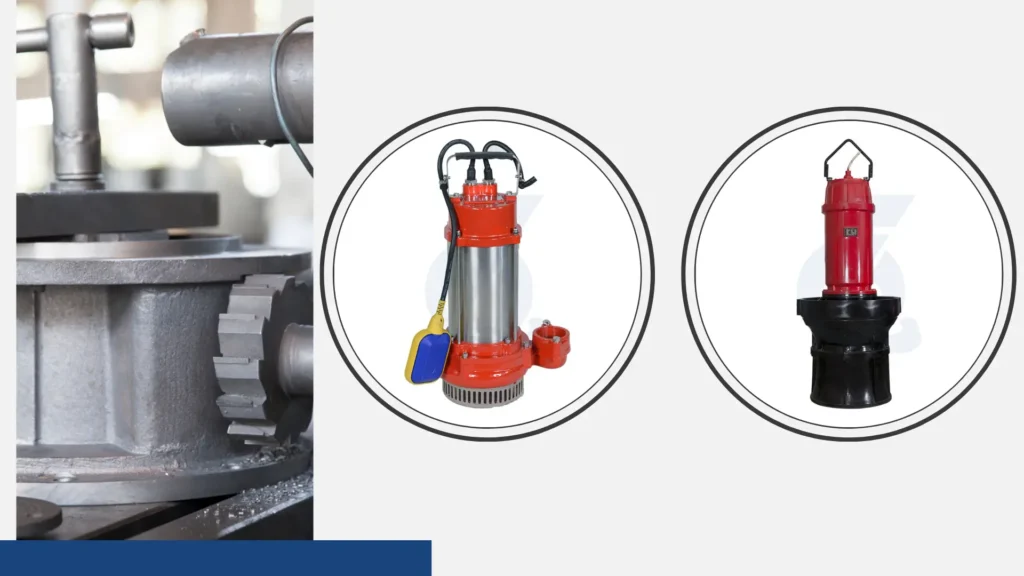

When activated, the motor drives an impeller—a rotating component with curved blades—that spins at high speeds.

As the impeller spins, it creates a centrifugal effect, pushing water outward from the center of the impeller and into the pump’s discharge pipe.

This force propels the water upward through the pipe, where it exits at the surface and is channeled into the farm’s irrigation network, such as pipes, hoses, or sprinklers, to reach crops.

What Makes Submersible Pumps Suitable for Diverse Agricultural Water Sources?

Adaptability to Varying Water Depths

One of the primary advantages of submersible pumps is their adaptability to varying water depths.

Farms may rely on shallow sources like small ponds (just a few feet deep) or deep wells.

Manufacturers produce submersible pumps with different power ratings and impeller designs to match these depths: low-power models work efficiently in shallow water, while high-torque variants can handle the pressure and resistance of deep wells, ensuring water is lifted consistently regardless of depth.

Durability in Contaminated Agricultural Water Sources

Agricultural water sources are rarely “clean”—they often contain sediments, sand, small rocks, algae, or mineral deposits.

Submersible pumps are built to withstand such conditions: many feature rugged impellers made from abrasion-resistant materials and intake screens that filter out large debris, preventing clogs and reducing wear on internal components.

This durability ensures they keep operating even in water with moderate levels of contaminants.

Reliable Performance in Still and Flowing Water

In stagnant ponds or reservoirs, where water movement is minimal, their design allows them to draw water steadily without relying on external currents.

In slow-moving streams or canals, they can adapt to gentle water flow, avoiding disruptions in suction.

This versatility ensures a consistent water supply, whether the source is calm or slightly dynamic.

Why Are Submersible Pumps Energy-Efficient for Agricultural Irrigation?

Minimized Energy Loss Through Submersion Design

Submersible pumps minimize energy loss during water extraction, a key factor in their efficiency.

The initial distance water needs to travel into the pump is negligible—often just a few inches—reducing the energy required to initiate flow.

This shorter “lift” translates directly to lower electricity usage, especially in deep wells where above-ground pumps would struggle with greater suction distances.

Advanced Motor Designs for Maximized Energy Conversion

Modern submersible pumps also feature advanced motor designs that maximize energy conversion.

High-efficiency motors convert electrical energy into mechanical energy with minimal waste—up to 90% efficiency in some models.

This means less electricity is lost as heat, resulting in lower utility bills for farmers, even during prolonged irrigation sessions.

Steady Operation to Avoid Energy Spikes

Many above-ground pumps cycle on and off frequently to maintain pressure, causing sudden surges in power consumption.

Submersible pumps, by contrast, can run continuously at a consistent speed, maintaining a stable flow rate without abrupt energy demands.

This steady performance not only reduces overall energy use but also extends the lifespan of the motor by avoiding wear from frequent starts and stops.

How Do Submersible Pumps Ensure a Consistent Water Supply for Crops?

Reliability Through Robust Mechanical Design

The reliability of submersible pumps stems from their robust mechanical design.

The sealed motor-pump unit is protected from external elements, reducing the risk of breakdowns caused by dust, debris, or weather.

The impeller and bearings are built to withstand continuous use—even running 24/7 during peak irrigation seasons—without overheating or wearing out quickly.

Adjustability to Meet Changing Water Demands

Many models come with variable speed drives or flow control valves that allow customization of water output.

By adjusting the pump’s settings, farmers ensure the right amount of water is delivered at each growth stage, preventing both under- and over-irrigation.

Consistent Water Pressure for Uniform Distribution

Pressure fluctuations can disrupt distribution—for instance, causing uneven sprinkler coverage or inconsistent drip rates.

These pumps, however, generate steady pressure due to their continuous operation and efficient impeller design, ensuring water reaches all parts of the field uniformly.

This consistency promotes balanced crop growth and reduces water waste.

What Types of Agricultural Irrigation Systems Can Use Submersible Pumps?

Compatibility with Drip Irrigation Systems

Submersible pumps are highly compatible with drip irrigation systems, which require low, steady pressure to deliver water directly to plant roots via emitters.

Their ability to maintain consistent flow rates ensures each emitter releases water evenly, preventing oversaturation or dry spots.

This makes them ideal for precision irrigation in orchards, vineyards, or vegetable gardens.

Effectiveness in Sprinkler Irrigation Systems

For sprinkler irrigation systems, which demand higher pressure to propel water through nozzles and cover large areas, submersible pumps are equally effective.

High-pressure models can power both stationary and mobile sprinklers, ensuring water is distributed over fields, pastures, or row crops uniformly.

Their steady pressure output prevents sprinklers from sputtering or producing uneven spray patterns.

Suitability for Flood Irrigation Systems

Even flood irrigation systems, which rely on moving large volumes of water into furrows or basins, benefit from submersible pumps.

High-capacity models can quickly fill irrigation ditches, ensuring water reaches all parts of the field without delay.

Their ability to handle large volumes makes them suitable for farms with extensive acreage or crops that require periodic flooding, such as rice paddies.

How Easy Is It to Install and Maintain Submersible Pumps on Farms?

Straightforward Installation Process

First, the water source is assessed to determine the pump’s required depth and size.

Once selected, the pump is attached to a discharge pipe and lowered into the water using a cable or rope—no heavy lifting equipment is needed for small to medium-sized models.

Above ground, the pipe is connected to the irrigation system, and the electrical cord is linked to a power source. Most farmers or farm workers can complete this process in a few hours with minimal training.

Simple Routine Maintenance Requirements

Regular checks involve inspecting the intake screen for clogs, examining the power cord for damage, and ensuring the discharge pipe is free of leaks.

For deeper wells, periodic lifting of the pump allows for cleaning the impeller and checking for wear, but this is often manageable with basic tools.

Submersible pumps have fewer moving parts exposed to the elements, reducing maintenance tasks.

Long Lifespan with Proper Care

With proper care, these pumps have a long lifespan—typically 8–15 years—depending on usage and water conditions.

Their sealed design protects internal components from corrosion and debris, minimizing the need for repairs. This longevity reduces replacement costs and ensures reliable performance for years.

What Are the Advantages of Submersible Pumps Over Other Irrigation Pumps?

Superior Efficiency in Water Extraction Compared to Above-Ground Pumps

Compared to above-ground pumps, submersible pumps are far more efficient at water extraction.

Their submersion eliminates “suction lift” limitations—the maximum height an above-ground pump can draw water.

In deep wells, this limitation forces above-ground pumps to work harder, wasting energy, while submersible pumps lift water directly from depth with minimal effort, making them up to 30% more efficient in such scenarios.

Quieter Operation Than Above-Ground Alternatives

Above-ground pumps generate noise from motor vibrations and water movement, which can be disruptive—especially for farms near residential areas or for workers in the vicinity.

Submersible pumps, however, are muffled by water, reducing noise levels significantly. This quiet operation improves working conditions and avoids disturbing neighbors.

Space-Saving Advantage Over Above-Ground Pumps

Above-ground pumps require a dedicated area for installation, including a concrete pad or base, which can take up valuable space on farms with limited land.

Submersible pumps, being underwater, leave the area around the water source unobstructed—freeing up space for other farm activities, storage, or vegetation. This is particularly beneficial for small farms or those with cluttered layouts.

How Do Submersible Pumps Handle Different Weather and Seasonal Changes?

Cold Weather Resilience for Winter Operations

Many models feature built-in heating elements or are made from materials that resist cracking in cold water.

Even if the surface of the water source freezes, the pump remains submerged in liquid water below the ice (since water is densest at 4°C, it stays liquid at the bottom), allowing it to continue operating.

This ensures irrigation can proceed during cold spells, critical for winter crops like wheat or greenhouse-grown vegetables.

Durability in Hot, High-Demand Seasons

During hot, dry seasons—when water demand peaks—these pumps excel at handling heavy workloads.

Their motors are equipped with thermal protection, which shuts off the pump if it overheats, but modern designs allow them to run for 12+ hours daily without reaching critical temperatures.

This durability ensures crops receive sufficient water during droughts or heatwaves, preventing wilting or stunted growth.

Resistance to Rain and Excess Moisture

Unlike above-ground pumps, which risk water damage from heavy rains or flooding, submersible pumps are already submerged—their sealed housing is impervious to additional moisture.

Even during monsoons or flash floods, the pump remains protected, ensuring uninterrupted operation.

How to Choose the Right Submersible Pump for Your Farm?

Evaluate Water Source Depth and Required Volume

For deep wells (over 50 feet), choose a pump with a high horsepower (HP) rating (1.5 HP or higher) to handle the pressure.

For shallow ponds or streams (less than 20 feet), a 0.5–1 HP pump may suffice.

Align with Irrigation System Pressure and Flow Requirements

Drip systems need low pressure (10–30 psi) and moderate flow rates, while sprinkler systems require higher pressure (30–80 psi).

Flood irrigation may demand high flow rates (100+ gallons per minute) but lower pressure.

Check the pump’s specifications—look for pressure (psi) and flow rate (gallons per minute) that match your system to ensure optimal performance.

Prioritize Durable Materials and Reliable Warranties

Choose pumps made from corrosion-resistant materials like stainless steel or cast iron, especially if your water is high in minerals or sediments.

Look for models with a warranty of 3–5 years, which covers defects in materials or workmanship.

A reputable brand with good customer support is also key—ensuring you can get replacement parts or service if needed.

Conclusion

Submersible pumps play a vital role in agricultural irrigation setups, offering efficiency, reliability, and versatility.

They work by being submerged in water sources, using centrifugal force to move water, and are suitable for various irrigation systems.

Their energy efficiency, ability to provide consistent water supply, and ease of installation and maintenance make them a great choice for farmers.

So, if you’re looking to improve your agricultural irrigation setup, a submersible pump is definitely worth considering.

And More: