Stainless steel submersible pumps are essential in various industries, including agriculture, construction, and wastewater management.

They are valued for their durability and efficiency, but regular cleaning is crucial for them to function optimally.

This article will explore the cleaning process for stainless steel submersible pumps, helping customers understand the importance of maintenance and the steps involved.

Why is Cleaning a Submersible Pump Important?

What Are the Consequences of Neglecting Cleaning?

Neglecting the cleaning of a submersible pump can lead to various issues such as reduced efficiency, increased wear and tear, and potential pump failure.

Accumulated debris can obstruct the impeller and impede water flow, which not only diminishes the pump’s performance but can also result in costly repairs or replacements if the problem goes unchecked.

How Does Cleaning Impact Pump Longevity?

Regular cleaning can significantly extend the lifespan of the pump. By removing contaminants and preventing corrosion, you can ensure that your pump operates effectively for years to come.

This proactive maintenance approach minimizes the likelihood of breakdowns and helps avoid the premature need for costly replacements, making it a smart investment for any operation relying on these pumps.

Does Cleaning Affect Performance?

Yes, cleaning directly impacts the pump’s performance.

A clean pump operates at optimal efficiency, providing better flow rates and pressure, which can help save energy and reduce operational costs.

Additionally, consistent cleaning allows the pump to maintain the necessary power to handle the specific demands of the pumping environment, ensuring reliable operation even under challenging conditions.

What Are the Safety Risks Associated with Dirty Pumps?

Dirty submersible pumps can pose several safety risks, including electrical hazards due to corrosion and mechanical failures that could lead to leaks, spills, or even accidents.

Furthermore, the build-up of mud, debris, or bio-film can create hazardous working conditions, making it crucial to prioritize regular cleaning to mitigate these potential dangers and safeguard worker health and safety.

What Materials Are Needed for Cleaning?

What Basic Cleaning Supplies Should You Prepare?

You will need basic cleaning supplies such as a soft brush, non-abrasive sponges, and mild soap.

These will help you clean without damaging the stainless steel surface.

Additionally, a bucket filled with warm water will provide the optimal environment for dissolving dirt and grime, making the cleaning process more efficient.

Are There Specific Cleaners Recommended for Stainless Steel?

Yes, there are specific cleaners designed for stainless steel that can effectively remove grime and prevent corrosion.

Look for products that are non-corrosive and safe for metal surfaces, as these will help maintain the pump’s integrity without risking damage.

Using the right cleaning agents will not only enhance the appearance of the pump but will also contribute to its long-term functionality.

Do You Need Any Specialized Equipment?

While basic supplies may suffice for routine cleaning, specialized equipment such as high-pressure washers can be beneficial for a deeper clean, especially in industrial applications.

High-pressure washers can effectively eliminate stubborn dirt and debris that might otherwise be difficult to remove, ensuring that the pump is thoroughly cleaned and ready for operation.

Is Personal Safety Equipment Required?

When cleaning pumps, it’s wise to use personal safety equipment like gloves and goggles.

This will protect you from cleaning agents and ensure a safe working environment.

Furthermore, wearing appropriate footwear with good grip will help prevent slips and falls, particularly if you are working in a wet or slippery area around the pump location.

How Often Should You Clean Your Pump?

What Factors Influence Cleaning Frequency?

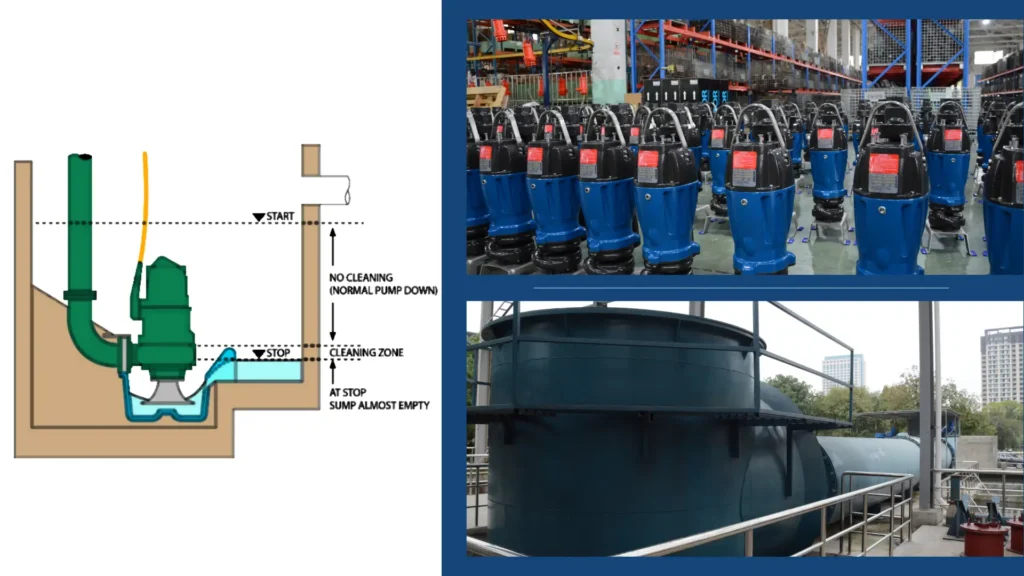

The frequency of cleaning largely depends on the pump’s application, environment, and the substances being pumped.

High-sediment environments may require more frequent cleaning, as the buildup of sediment can quickly lead to obstructions.

Conversely, pumps operating in cleaner environments may need less frequent maintenance, but it’s essential to assess the conditions regularly and adjust the cleaning schedule accordingly.

How Can You Determine When Cleaning is Necessary?

Signs such as decreased flow rates, unusual noises, or visible debris buildup are indicators that it’s time for cleaning.

Regular inspections can help determine the right cleaning schedule; for instance, noting frequency and extent of these signs can assist in developing a proactive maintenance strategy to preemptively address any potential issues.

Does Seasonal Change Affect Cleaning Frequency?

Yes, seasonal changes can impact cleaning frequency. For instance, during rainy seasons, pumps may encounter more debris, necessitating more frequent maintenance.

This is particularly important in areas where runoff brings additional dirt and organic matter into the pumping system, requiring adjustments in your cleaning routine to adapt to environmental changes.

How Can a Maintenance Schedule Help?

Establishing a maintenance schedule can streamline the cleaning process, ensuring that your pump is serviced regularly and runs efficiently without unexpected breakdowns.

A well-defined schedule not only helps maintain optimal performance but also allows for systematic record-keeping, making it easier to track the pump’s condition and plan for any necessary part replacements.

What Are the Steps for Cleaning a Stainless Steel Submersible Pump?

How Do You Prepare for Cleaning?

Preparation involves turning off power to the pump, disconnecting it from any power source, and ensuring the area is safe for maintenance.

Also, gather your cleaning supplies to have everything ready at hand, reducing downtime and allowing you to perform the cleaning process efficiently and systematically.

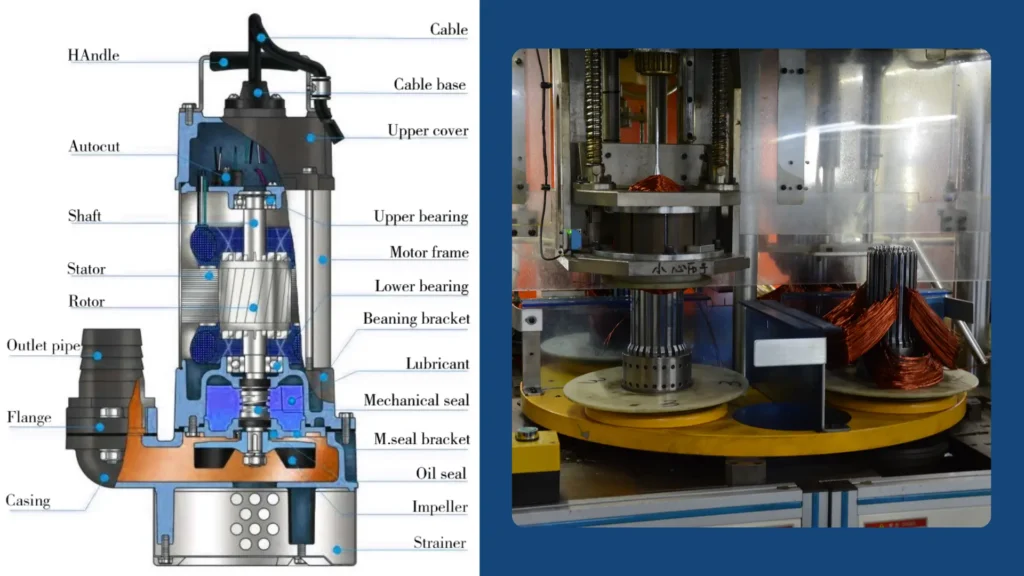

What Is the Proper Way to Disassemble the Pump?

Carefully remove any parts that require cleaning.

Follow the manufacturer’s guidelines for disassembly to avoid damaging the pump during the process.

Being methodical in your approach also ensures that you can reassemble the pump correctly, maintaining its performance and structural integrity.

How Should You Clean the Components?

Using a soft brush and mild soap, gently clean the components to remove dirt and grime.

Pay special attention to crevices and surfaces where debris can accumulate, as these areas can significantly impact the pump’s efficiency if not properly maintained.

Taking your time during this process is crucial for a thorough clean that will benefit the pump in the long run.

What Is the Best Way to Reassemble the Pump After Cleaning?

Once cleaned, ensure all parts are dry before reassembling.

Follow the manufacturer’s instructions carefully to ensure all components are securely in place, as improper reassembly can lead to leaks or mechanical failures.

Double-checking each step during reassembly can provide peace of mind that the pump is ready for reliable operation once again.

What Precautions Should You Take?

How Can You Avoid Damage During Cleaning?

To avoid damage, always use non-abrasive cleaning methods and avoid harsh chemicals that could corrode the stainless steel.

Additionally, it’s important to use tools designed specifically for cleaning stainless steel surfaces, as they are less likely to scratch or mar the material, helping maintain the pump’s surface integrity and prolonging its lifespan.

Should You Wear Protective Gear?

Yes, wearing gloves and goggles is advisable to protect yourself from cleaning agents and any sharp components during cleaning.

Furthermore, long-sleeved clothing can provide an extra layer of protection against accidental scrapes or cuts, ensuring that you are safeguarded against the various hazards that may arise in the cleaning process.

What About Electrical Safety?

Ensure that the pump is disconnected from any power source before cleaning to prevent electrical hazards.

Taking this extra step not only protects you from the risk of electric shock but also prevents potential damage to the pump’s electrical components, which can result from the introduction of water or cleaning agents.

Are There Risks When Cleaning in Certain Conditions?

Cleaning in wet or slippery conditions can pose safety risks.

Always ensure the area is dry and safe prior to beginning the cleaning process, as this will help reduce the likelihood of slips and falls, which can lead to injuries.

Additionally, good lighting in the cleaning area can enhance visibility and help you avoid hazards while working on the pump.

Also Read:

- Maintenance and Repair of Industrial Submersible Pumps

- Post-Flood Inspection and Maintenance of Submersible Pumps

Conclusion

Cleaning a stainless steel submersible pump is essential for maintaining its performance and longevity.

By understanding the cleaning process, the tools needed, and the precautions to take, customers can ensure their pumps operate efficiently and safely for many years.

Moreover, implementing a regular cleaning and maintenance routine not only protects your investment but also contributes to a safer working environment for everyone involved.

Prioritize the care of your submersible pump to enjoy its benefits fully, ensuring that it consistently provides optimal performance in all applications.