Choosing the right submersible pump can be challenging with so many options available.

The best choice depends entirely on your specific requirements—whether for home use, industrial applications, or agricultural needs.

This guide breaks down the key factors to consider when selecting a submersible pump, helping you make an informed decision that matches your unique situation.

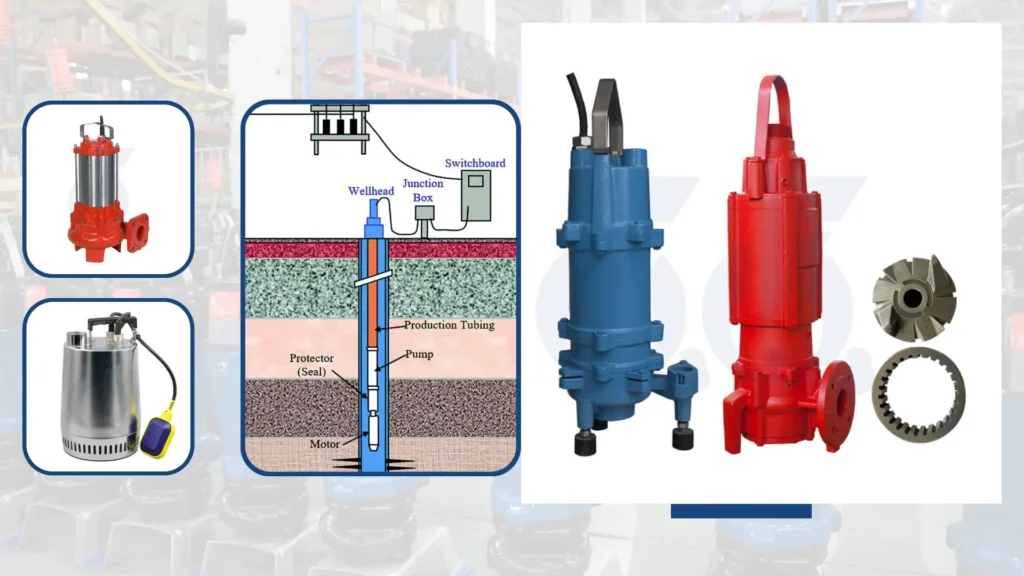

What Are the Main Types of Submersible Pumps?

Clean Water Pumps

Clean water pumps are specifically designed for pumping clear water with minimal or no solid particles.

These pumps are ideal for applications such as household water supply, garden irrigation, and filling swimming pools.

They typically have a simple design and are efficient at moving water quickly while maintaining a clean output, making them an excellent choice for residential and light commercial use.

Dirty Water Pumps

Dirty water pumps are robust and built to handle more challenging conditions, such as muddy water, sand, and small debris.

These pumps are essential for situations like draining flooded areas, emptying ponds, or managing stormwater.

They often feature larger intake screens and more powerful motors to manage the additional strain of pumping water mixed with solids, ensuring effective drainage and flood control.

Sewage Pumps

Sewage pumps are equipped with cutting mechanisms that allow them to process and pump waste and solid materials found in sewage.

They are crucial for systems like septic tanks and municipal wastewater management, where they transport waste to treatment facilities.

These pumps are designed to handle thick, viscous materials and can operate in harsh environments, making them indispensable for both residential and industrial applications.

Borehole Pumps

Borehole pumps are specialized for deep well applications, characterized by their long, narrow designs.

They are capable of delivering high-pressure water from significant depths, making them suitable for agricultural irrigation and municipal water supply.

These pumps often feature multi-stage designs to increase pressure and can be used in various water extraction scenarios, from domestic wells to deep boreholes.

And More:

- Types of Submersible Pumps in Wastewater Treatment Plants

- Understanding Industrial Submersible Pumps: Definition, Advantages, and Types

- Types and Applications of Submersible Pumps in Agriculture

How Do You Determine the Right Pump Size?

Flow Rate Requirements

To select the appropriate pump size, start by calculating the required flow rate, typically measured in gallons per minute (GPM).

This requirement will vary based on your specific application—whether you’re filling a swimming pool, irrigating fields, or supplying water for a household.

Understanding your flow needs ensures that the pump can meet your demands without overworking or underperforming.

Total Head Pressure

Total head pressure is another critical factor in pump selection. This includes both the vertical lift (the height the water needs to be raised) and the horizontal distance the water must travel.

Ensuring your pump can handle the total head pressure is vital for efficient water delivery.

Failure to account for this can result in inadequate performance and increased energy consumption.

Power Supply Compatibility

Lastly, check the power supply compatibility for the pump you are considering. Pumps may operate on different voltages, such as 120V, 230V, or 3-phase power.

It’s essential to ensure that your electrical system can support the pump’s power requirements to avoid any operational issues.

This step helps in preventing potential damage to the pump and ensures efficient operation.

What Materials Are Best for Durability?

Stainless Steel Pumps

Stainless steel pumps are renowned for their exceptional resistance to corrosion, making them ideal for use in harsh environments such as saltwater or areas exposed to chemicals.

This material not only withstands rust and degradation but also maintains structural integrity over time, ensuring reliable performance.

Stainless steel pumps are commonly used in industrial applications, food processing, and water treatment facilities, where durability is crucial.

Their longevity often justifies the higher upfront cost, as they require less frequent replacement and maintenance.

Cast Iron Pumps

Cast iron pumps are known for their durability and cost-effectiveness, making them a popular choice for general freshwater applications.

They are robust and can handle significant wear and tear, which is beneficial in construction sites or municipal water systems.

However, one downside is that cast iron is prone to rust if not properly maintained, especially in environments with high moisture.

Regular maintenance, such as painting or coating, can help extend the life of cast iron pumps, but users should be aware of the potential for corrosion over time.

Thermoplastic Pumps

Thermoplastic pumps are lightweight and highly resistant to corrosion, making them an excellent choice for residential and light commercial applications.

These pumps are made from various plastic materials that can withstand chemical exposure without degrading.

Their lightweight nature makes them easy to install and relocate, making them ideal for temporary setups or smaller systems.

Additionally, thermoplastic pumps typically require less maintenance than metal pumps, further enhancing their appeal for users looking for convenience and reliability.

When Should You Choose a Single-Phase vs. Three-Phase Pump?

Single-Phase Pumps

Single-phase pumps are typically suitable for residential and small-scale applications, operating on standard electrical outlets (usually 120V or 240V).

They are easier to install and require less complex electrical setups, making them ideal for homeowners who need pumps for tasks like draining pools or irrigation.

However, they may not be as powerful as three-phase pumps and can struggle in applications requiring high flow rates or significant pressure.

Three-Phase Pumps

Three-phase pumps are designed for more demanding applications, such as industrial or agricultural use, where higher power capacity is essential.

They provide greater efficiency and can handle larger workloads without overheating, making them ideal for tasks that require continuous operation.

While the initial installation may be more complex and costly due to the need for three-phase electrical systems, these pumps often deliver better performance in heavy-duty operations.

Energy Efficiency Considerations

In many cases, three-phase pumps are more energy-efficient than their single-phase counterparts, particularly in heavy-duty applications.

They can operate at lower current levels, reducing energy consumption and overall operating costs.

This efficiency makes them a more sustainable choice for industries looking to minimize energy usage while maximizing productivity.

How Important Is Pump Efficiency?

Energy Star Ratings

Pumps with higher Energy Star ratings are designed to consume less electricity, contributing to lower long-term operational costs.

Choosing energy-efficient pumps can significantly reduce your energy bills and carbon footprint, making them an environmentally friendly option.

These ratings are a reliable indicator of a pump’s performance and efficiency, guiding consumers toward more responsible choices.

Variable Speed Options

Variable speed pumps are equipped with technology that allows them to adjust their performance based on demand.

This feature optimizes efficiency by preventing energy waste during periods of low water flow.

For example, in residential applications, a variable speed pump can slow down when less water is needed, saving energy and extending the pump’s lifespan due to reduced wear and tear.

Maintenance Impact on Efficiency

Regular maintenance is crucial for ensuring that pumps operate at peak efficiency.

Neglecting maintenance can lead to decreased performance, increased energy consumption, and premature failure.

Routine checks, cleaning, and servicing can help identify issues early, ensuring that the pump runs smoothly and efficiently without unnecessary power drain.

And More:

- Impact of Energy Efficiency on Operational Costs of Submersible Pumps

- Key Performance Parameters of Industrial Submersible Pumps

What Safety Features Should You Look For?

Overload Protection

Overload protection is a critical safety feature that prevents motor burnout during power surges or when the pump encounters blockages.

This mechanism automatically shuts down the pump when it detects excessive current draw, safeguarding the motor from overheating and potential damage.

By incorporating overload protection, you enhance the longevity of the pump and reduce the risk of costly repairs or replacements, ensuring reliable operation even in challenging conditions.

Thermal Cut-Off Switches

Thermal cut-off switches are designed to automatically shut off the pump if it overheats, thereby preventing damage from excessive temperatures.

This feature is especially important in applications where pumps may run continuously or under heavy loads.

By terminating operation during overheating conditions, thermal cut-off switches not only extend the lifespan of the pump but also enhance safety by reducing the risk of fire or equipment failure.

Waterproof Seals and Insulation

Waterproof seals and insulation are essential features for pumps that operate in submerged conditions.

These components protect the electrical parts of the pump from water ingress, which can lead to short circuits and electrical hazards.

Proper sealing and insulation not only ensure safe operation but also contribute to the pump’s durability by preventing corrosion and damage from moisture, making them vital for both residential and industrial applications.

How Does Installation Affect Performance?

Proper Sizing of Pipes and Fittings

The sizing of pipes and fittings directly impacts pump performance. Undersized pipes can restrict flow, leading to pressure drops and reduced efficiency.

This restriction can cause the pump to work harder, increasing energy consumption and wear.

Conversely, properly sized pipes facilitate optimal flow rates, ensuring that the pump operates within its designed parameters and delivers water effectively to the intended application.

Correct Submersion Depth

Ensuring the correct submersion depth is crucial for optimal pump performance.

When pumps are submerged too shallowly, they may not achieve adequate suction, leading to inefficient operation or even dry running.

Dry running can cause severe damage to the pump, including overheating and component failure.

Maintaining the appropriate submersion depth helps ensure efficient suction and prolongs the life of the pump.

Secure Mounting

Secure mounting is vital for preventing vibrations and misalignment that can lead to wear and tear over time.

Properly mounting the pump minimizes movement during operation, which can cause stress on components and reduce efficiency.

Additionally, a well-secured pump reduces noise and operational disturbances, contributing to a more reliable and longer-lasting system.

What Maintenance Practices Extend Pump Life?

Regular Cleaning

Regular cleaning is a fundamental maintenance practice that involves removing debris and sediment that can clog impellers and reduce pump efficiency.

Accumulated dirt and particles can hinder the flow of water, forcing the pump to work harder and potentially leading to overheating.

By routinely cleaning the pump and its components, you help maintain optimal performance and prevent costly downtime.

Lubrication of Moving Parts

Lubricating moving parts, such as seals and bearings, is essential for ensuring smooth operation and reducing friction.

Proper lubrication helps to extend the life of these components by preventing wear and tear.

Regularly checking and applying the appropriate lubricant can significantly enhance the pump’s performance, minimize noise, and reduce the risk of mechanical failure.

Periodic Inspection of Electrical Components

Periodic inspection of electrical components is crucial for preventing failures due to worn-out wiring or connections.

Regular checks can identify frayed wires, loose connections, or signs of corrosion, allowing for timely repairs or replacements.

By maintaining the electrical integrity of the pump, you ensure reliable operation and mitigate the risk of unexpected breakdowns, contributing to the overall longevity of the system.

Conclusion

Selecting the best submersible pump depends on understanding your specific needs—whether it’s for clean water, sewage, or industrial use.

Factors like flow rate, material durability, energy efficiency, and safety features all play crucial roles in making the right choice.

By assessing these elements carefully, you can invest in a pump that delivers reliable performance while minimizing long-term costs.

Remember, the right pump not only meets your current demands but also adapts to future requirements, ensuring years of trouble-free operation.

Start by evaluating your needs, and you’ll find the perfect pump for your situation.