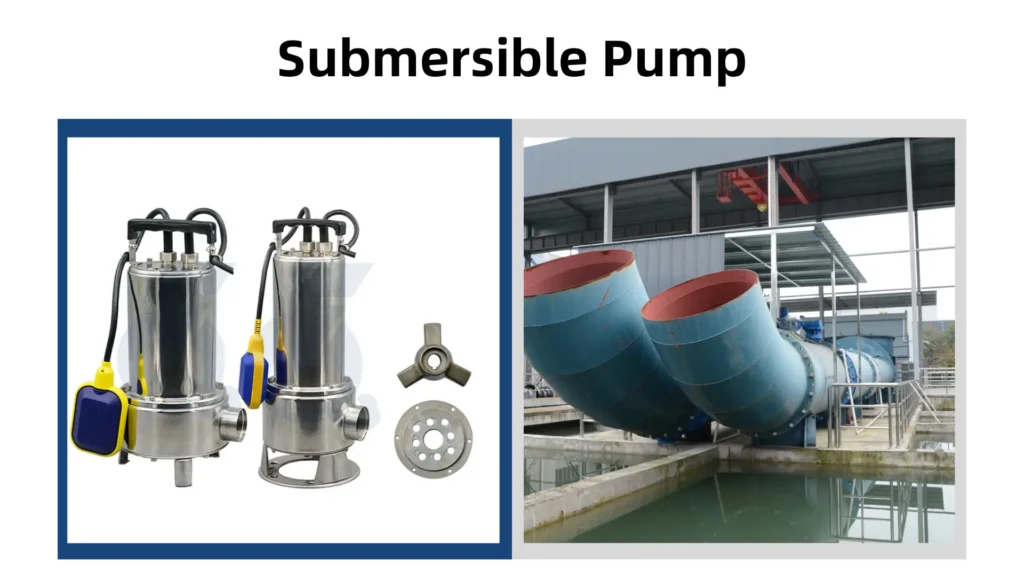

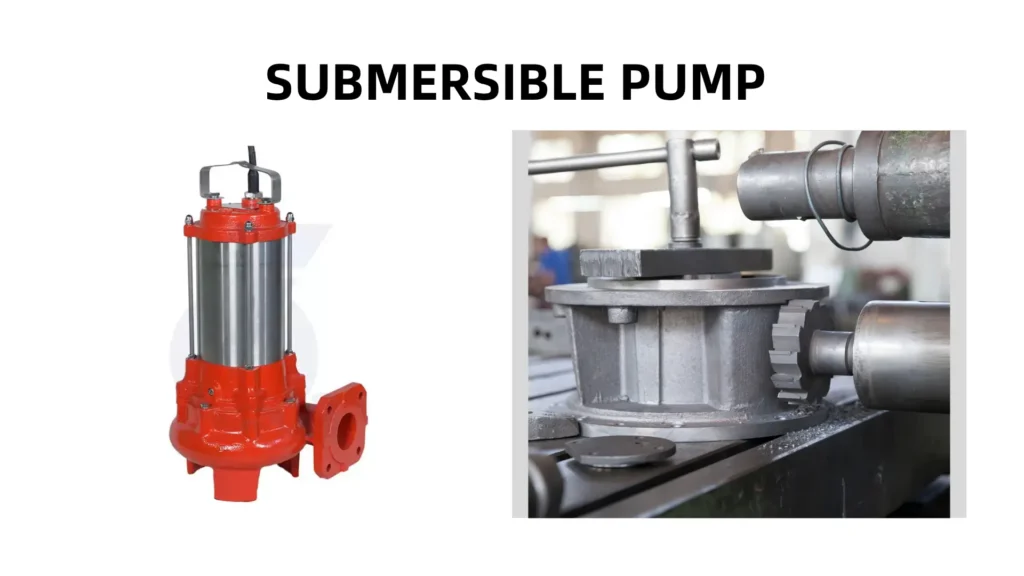

Submersible pumps are designed to operate underwater, where the surrounding liquid helps cool and lubricate the motor.

But what happens if the water runs out? Running a submersible pump dry—even briefly—can cause serious damage.

In this article, we’ll explain why dry running is harmful, how to prevent it, and what to do if your pump accidentally operates without water.

What Happens When a Submersible Pump Runs Dry?

The motor overheats rapidly

Without water to absorb heat, the pump’s internal temperature spikes, risking permanent damage to windings and seals.

This overheating can lead to costly repairs or complete pump failure. Regular monitoring of water levels is essential to prevent this scenario.

Mechanical seals fail prematurely

These critical components rely on water for lubrication. Dry operation causes friction, leading to cracks and leaks.

Replacing failed seals can be expensive and labor-intensive, making it crucial to maintain proper operating conditions.

Impeller and bearings wear out faster

The lack of cooling and lubrication accelerates wear on moving parts, shortening the pump’s lifespan.

Over time, this can lead to decreased efficiency and increased maintenance costs. Ensuring adequate water supply can significantly extend the life of these components.

Energy waste increases

A dry-running pump consumes electricity while delivering no useful work, raising operational costs.

This inefficiency not only affects your electricity bill but also contributes to unnecessary wear on the pump. Implementing safeguards can help mitigate these energy losses.

Why Do Some Pumps Claim to Be “Dry-Run Safe”?

Built-in thermal protection exists

Some models automatically shut off when overheating is detected, preventing catastrophic failure.

This feature provides an essential safety net for users who may forget to monitor water levels. However, it’s crucial to understand how these systems function to ensure they are effective.

Specialized materials resist heat damage

Advanced ceramics and reinforced polymers can better withstand temporary dry conditions.

These materials enhance the durability and reliability of the pump in challenging environments. Investing in pumps with high-quality materials can lead to reduced maintenance and increased longevity.

Float switches prevent operation without water

These accessories cut power when water levels drop too low for safe pumping.

Float switches provide a simple yet effective way to protect the pump from dry running. Regular testing of these switches is advisable to ensure they function correctly.

Not all “dry-safe” pumps are equal

Always check manufacturer specifications—some tolerate only brief dry periods while others handle extended operation.

Understanding these limits is essential for choosing the right pump for your application. Consulting with a professional can help clarify which model best suits your needs.

How Long Can a Submersible Pump Run Dry Before Damage Occurs?

Most standard pumps fail within minutes

Conventional models may sustain permanent damage in as little as 30-60 seconds of dry running.

This rapid failure can lead to costly repairs or the need for a complete replacement. Regular maintenance and monitoring can help prevent such scenarios.

Quality affects tolerance levels

Better constructed pumps with superior materials often withstand dry conditions longer than cheap alternatives.

Investing in high-quality pumps can save money in the long run by reducing the risk of damage.

Always consider the materials used in pump construction when making a purchase.

Ambient temperature matters

Pumps fail faster in hot environments where heat dissipation is already challenging.

High temperatures can exacerbate the overheating issues caused by dry running. Ensuring proper ventilation and cooling can help mitigate these effects.

Prior wear reduces dry-run tolerance

Older pumps with existing seal or bearing issues will succumb to dry operation more quickly.

Even minor wear can significantly impact a pump’s ability to handle dry conditions. Regular inspections and timely repairs are essential for maintaining pump performance and longevity.

And More:

Why Is My Submersible Pump Overheating?

What Are the Warning Signs of Dry Running Damage?

Burning smell from the motor

Overheated insulation produces distinct odors that indicate serious electrical damage.

This smell is often a precursor to motor failure and should be addressed immediately. Ignoring this warning can lead to complete motor burnout and costly repairs.

Reduced water pressure

Worn impellers or damaged seals decrease pumping efficiency after dry running incidents.

This reduction in pressure can affect the entire system’s performance. Regular monitoring of water pressure can help identify issues early on.

Unusual vibrations or noise

Warped components create imbalance and strange operational sounds post-dry running.

These vibrations can lead to further mechanical issues if not addressed promptly. Listening for unusual noises during operation can be a key indicator of underlying problems.

Visible seal leakage

Failed mechanical seals often show external water seepage around the motor housing. This leakage can compromise the pump’s functionality and lead to additional damage.

Regularly inspecting seals for wear and replacing them as needed can help prevent significant issues.

How Can I Prevent My Pump From Running Dry?

Install automatic water level controls

Float switches or electronic sensors reliably deactivate pumps when water is insufficient. These controls can be a lifesaver, preventing damage during unexpected water level drops.

Ensure that the sensors are installed correctly and tested regularly. Regular maintenance of these controls is essential for their reliability.

Choose pumps with built-in protection

Modern models with thermal cutoffs and dry-run detection provide essential safeguards.

These features help to prevent overheating and extend the lifespan of the pump. Investing in a quality pump with these attributes can save you from costly repairs.

Always check the manufacturer’s specifications to understand the protective features offered.

Implement regular maintenance checks

Periodically inspect for proper submersion and test protection systems. Scheduled maintenance can help identify potential issues before they escalate into serious problems.

Keeping a maintenance log can aid in tracking the history and health of your pump. This proactive approach ensures that your pump operates efficiently and reliably.

Monitor water sources carefully

Be especially vigilant with wells or reservoirs that may experience sudden level drops.

Regularly checking water levels can help you anticipate potential issues before they arise. Installing additional monitoring equipment can provide real-time data on water levels.

Awareness of environmental changes can also help in predicting fluctuations in water availability.

Also Read:

What Should I Do If My Pump Accidentally Runs Dry?

Immediately power it down

Quick shutdown minimizes potential damage when dry running is detected. This action helps prevent overheating and protects the motor from further harm.

Always have a clear and accessible power switch for emergencies. Training staff on emergency procedures can ensure quick responses in such situations.

Allow complete cooling

Let the pump sit for several hours before restarting to prevent thermal shock. Rapid temperature changes can cause additional stress on the components.

During this time, inspect the surrounding area for any potential hazards. Cooling is crucial to ensure the pump is safe to operate again.

Inspect for visible damage

Check seals, wiring, and housing before attempting to reuse the pump. Look for any signs of wear or overheating that could indicate underlying problems.

Documenting any damage can assist with future maintenance decisions. If significant damage is found, consult a professional before proceeding.

Test carefully with water

Restart submerged and monitor closely for performance issues or leaks. Observing the pump during initial operation can reveal problems that may not have been apparent during inspection.

If any unusual noises or vibrations occur, shut the pump down immediately. A cautious approach can help prevent further damage and ensure safe operation.

Can Dry Running Damage Be Repaired?

Seal replacements are often needed

Failed mechanical seals represent the most common repairable dry-run damage.

These seals play a crucial role in maintaining water integrity and preventing leaks. Replacing seals can restore the pump’s functionality and efficiency.

It’s vital to use high-quality replacement seals to ensure durability and prevent future issues.

Motor rewinding may be required

Severe overheating sometimes necessitates professional motor refurbishment. This process involves rewinding the motor coils, which can be complex and requires specialized skills.

Depending on the extent of the damage, it may also involve replacing other electrical components.

A thorough inspection by a qualified technician can determine whether rewinding is the best option.

Complete replacement is sometimes cheaper

For older pumps, repair costs may exceed the price of a new dry-run protected model.

This is especially true if the pump has multiple issues that need addressing. Investing in a new pump with modern features can provide better reliability and efficiency.

Evaluating long-term costs and benefits can help you make the most informed decision.

Professional assessment is recommended

Have a technician evaluate significant dry-running incidents to determine repair feasibility.

This evaluation can identify not just visible damage but also underlying issues that may not be apparent.

Timely assessments can prevent further damage and additional costs down the line. Relying on an expert’s knowledge can ensure that any repairs are effective and safe.

Are There Applications Where Dry Running is Unavoidable?

Dewatering operations carry higher risks

Pumps used to empty tanks or flood areas will eventually encounter dry conditions.

These operations often require constant monitoring to prevent dry running. Implementing automated controls can help mitigate risks during such processes.

Understanding the specific environmental conditions can aid in planning for potential dry runs.

Recirculating systems need special precautions

Closed loops with potential for air pockets require careful design to prevent dry running. Incorporating air separators or automatic air vents can help maintain system integrity.

Regular maintenance and checks are essential to ensure that these systems function correctly.

A well-designed system can minimize the risk of dry operation significantly.

Industrial processes may demand dry-run capability

Certain manufacturing applications justify investing in heavy-duty dry-run tolerant pumps.

These pumps are engineered to handle intermittent dry conditions without sustaining damage.

Understanding the specific requirements of your industrial processes can guide equipment choices. Consulting with equipment manufacturers can provide insights into the best options available.

Always consult an expert for special cases

Unusual applications may need customized solutions to handle intermittent dry operation.

An expert can recommend tailored designs that accommodate specific operational challenges.

Collaboration with engineers can lead to innovative solutions that improve efficiency and reliability. Investing in professional advice can ultimately save time and resources in the long run.

Conclusion

While no submersible pump benefits from dry running, understanding the risks and prevention methods can save you from costly repairs and replacements.

Investing in quality pumps with dry-run protection, implementing proper monitoring systems, and responding quickly to incidents will maximize your equipment’s lifespan.

For applications where dry conditions are possible, consider specially designed pumps that can handle these challenging situations.