The use of submersible pumps is widespread in a multitude of sectors.

They are an indispensable component of an irrigation system in agriculture, as they ensure a reliable source of water to crops, especially in the case of arid regions.

Wastewater management uses these pumps to transfer sewage from homes to treatment facilities for public health safety.

Submersible pumps are also extensively used in construction-for dewatering excavation sites and, in turn, preventing flooding and ensuring safety of workers.

They are versatile and effective, making them a desired choice in many industries.

Energy efficiency in submersible pumps is relevant to both operational cost savings and environmentally sound operation.

Energy saved by efficient pumps translates into an electricity cost savings.

In an era where sustainability is ever more important, such investments pay back to the company accounts while also being friendly to the environment by reducing carbon footprints.

Prioritizing energy efficiency investments will enable businesses to make improvements in sustainability while aligning with global efforts to combat climate change.

Understanding Energy Efficiency

Energy Efficiency Explained

It means energy efficiency can actually perform the same job with lesser energy produces output.

In submersible pumps, this is where hydraulic energy produced is maximized with the least possible consumption of electrical energy.

An energy-efficient pump runs well with lesser energy requirements-it is worth consideration by firms wanting to make some savings and minimize their environmental footprint.

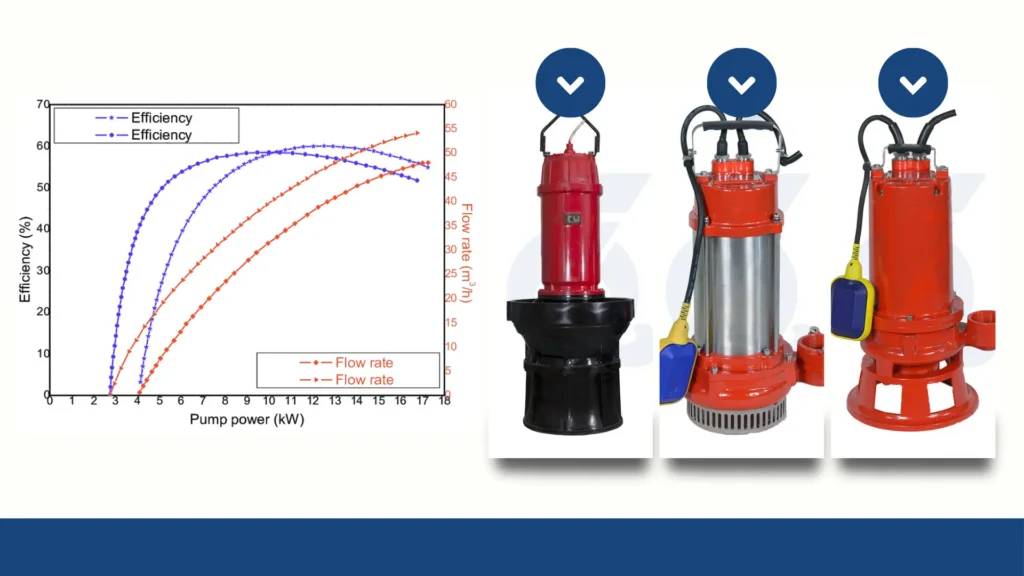

Efficiency Measurement Parameters

The efficiency of submersible pumps is typically assessed by using different types of metrics, such as overall efficiency percentage, which specifies the percentage of input energy which is converted into useful hydraulic energy.

Specific energy consumption measures the energy consumed per unit of fluid pumped.

The Power factor of the pump expresses its electrical efficiency as well as performance.

Therefore, the investor-the buyer has a grasp of possible savings through energy-efficient models.

Benefits of High Energy Efficiency

High energy efficiency in submersible pumps means great benefits.

On the first hand, the savings in energy budgets will be considerable, especially where the operations are running continually since these will build up over a long period.

Energy-efficient pumps generally have a longer life span due to less wearing out of parts, while maintenance expenses are lower.

Besides, they are environmentally sustainable by reducing emission carbon, which is an appealing factor for any business wishing to improve its corporate social responsibility.

Operational Costs of Submersible Pumps

Operational Cost Factors

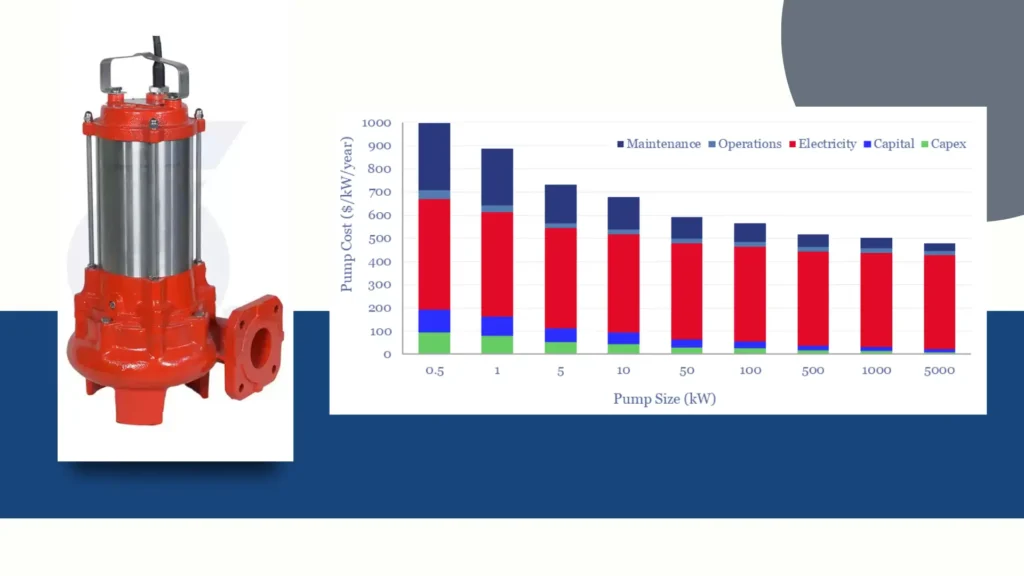

There are various components of operational cost related to submersible pumps.

The most significant is energy cost, which varies depending on how efficient the pump is and for how long it is kept running.

Repair costs that are incurred from routine maintenance inspections, repairing, and buying spare parts also become components of the overall operational costs.

Awareness of these components remains very important for any business that wants to control budgets and is looking for opportunities to cut costs.

What Energy Consumption Does to Operational Costs

Energy consumption is a significant cost factor in the operation of submersible pumps.

Non-energy-efficient pumps are capable of ramping up electric bills during applications needing continuous pumping.

For example, an inefficient pump may cost twice or thrice the normal electricity expense, in turn affecting the profitability of the operation.

Investment on energy-efficient pumps will save the business from incurring such costs while improving its financial performance.

The Hidden Costs of Improper Pumps

Inefficient pumps often incur hidden costs that are unknown at first.

This cost might be due to wear and tear on an increased number of parts with increased frequency of repair and replacement of worn-out components.

Inefficient pumps also cause system failures or unplanned downtime losses in production or revenue.

Understanding these costs would then allow companies to put the necessary frameworks in place to improve their decision-making processes with regard to pump purchasing and operating frameworks.

The Role of Energy Efficiency in Cost Reduction

Energy Efficiency vs. Conventional Pumps

The difference is indeed very clear when you compare energy-efficient submersible pumps with traditional submersible pumps.

Energy-efficient pumps are engineered with high-technology features that make them work optimally along with low energy consumption.

It is during this fair comparison that you’ll realize the long-term financial argument behind investing in energy-efficient technology, as it is an energy-efficient pump in itself that has very low operational costs, besides costs saved across time in its electricity consumption.

Long Term Cost Benefits Through Efficiency

Investing in an energy-efficient submersible pump means long-term savings, which are obviously very substantial.

The high initial price along the lines will generally end up being compensated by lower energy bills and maintenance costs.

In several years, these savings will serve to counterbalance that price, making energy efficiency financially sound for businesses striving for better margins.

Maintenance Cost Impact

The energy-efficient pumps are naturally less maintenance than the conventional because of the optimized designs.

Since these pumps run at their optimal level, stress on components does not occur that much, which leads to less wear and tear.

Hence, a business will have lower maintenance costs and better reliability, which ensures uninterrupted operation and therefore better productivity.

Selecting Energy-Efficient Submersible Pumps

Features Relevant to Selection

While choosing submersible pumps which guarantee saving energy, some of the specifications worthy of consideration are high-efficiency motor, variable frequency drives, and improved impeller designs.

High-efficiency motors convert electric energy into mechanical energy more effectively than normal motors.

VFDs allow the pumping flow rate to be adjusted, thus optimizing energy use.

Additionally, well-designed impellers enhance fluid dynamics during travel through a pump, greatly improving performance and efficiency.

Certifications and Standards

Check for pumps certified or conforming to industry standards for energyefficiency such as the Energy Star label or other similar certifications.

Such standards ensure that the pumps have undergone rigorous testing and verification for their efficiencies, making any purchase worthwhile.

By knowing how important such certifications are for the purchase, a business would understand their impact on the decisions made.

Feasibility Evaluation with Energy Ratings

Before one buys submersible pumps, one must be well versed with energy ratings.

It is evident from the ratings that the higher the rating, the better is the energy efficiency, which would mean a considerable saving in the long run.

Through the understanding of ratings of energy use and performance, one can ascertain which pump will serve his or her needs best in operating conditions and lead him or her to use pumps with optimum efficiency.

Addressing Common Misconceptions

Myths Related to Energy Efficient Pumps

There are a number of myths about energy-efficient pumps.

They say that energy-efficient pumps are very expensive-perhaps much more than conventional pumps.

While it is true that the initial costs outweigh the costs of conventional pumps, these costs are far outweighed by the consumption of energy and maintenance costs towards a more effective waiting.

This kind of myth-busting is going to be important when it comes to informing and empowering potential buyers in their choices.

Initial Spending vs. Savings in the Future

Some customers do not want to spend money on energy-saving pumps because they cost much more compared to conventional ones at the beginning.

Nevertheless, future payment for energy bills and maintaining the pumps should serve for the calculation of benefits in reference to best output.

A comprehensive cost analysis exposes how energy-efficient pumps would be beneficial in investing over the years.

The Importance of Proper Installation

The installation must be carried out correctly so that energy-efficient pumps could work at their best.

And improper installation not only makes these pumps underperform but also causes them to consume a lot more than necessary.

This necessitates investing in a quality service that comes with professional installation so as to gain energy-efficient submersible pumps and their best operation.

Conclusion

In summary, investing in energy-efficient submersible pumps can produce fairly considerable savings on operational costs and leave a less substantial carbon footprint.

Important considerations for potential buyers include understanding the meaning of energy efficiency in evaluating operational costs to clarify misperceptions.

These are very critical in making purchasing decisions as well as in contributing to overall operational success.

Making informed choices in submersible pump selection can dramatically impact the economics and ecology of operations.

Energy efficiency enhances the sustainability agenda of many businesses while saving for the long term.

For those who would consider getting submersible pumps, this moment is for checking energy-efficient alternatives.

Assess your needs, consult your industry representatives, and make a decision that will benefit both your bottom line and the planet.

Investing in efficient technology now will certainly yield dividends some years later to ensure that your operations remain competitive and sustainable.