Submersible pumps are vital in industries like agriculture, construction, and wastewater management, but their efficiency depends on more than just mechanical design.

Understanding how fluid mechanics principles influence their operation can help buyers make smarter choices.

This article explains the key connections between submersible pumps and fluid dynamics—without complex equations—so you can select the right pump for your needs.

How Do Submersible Pumps Work Underwater?

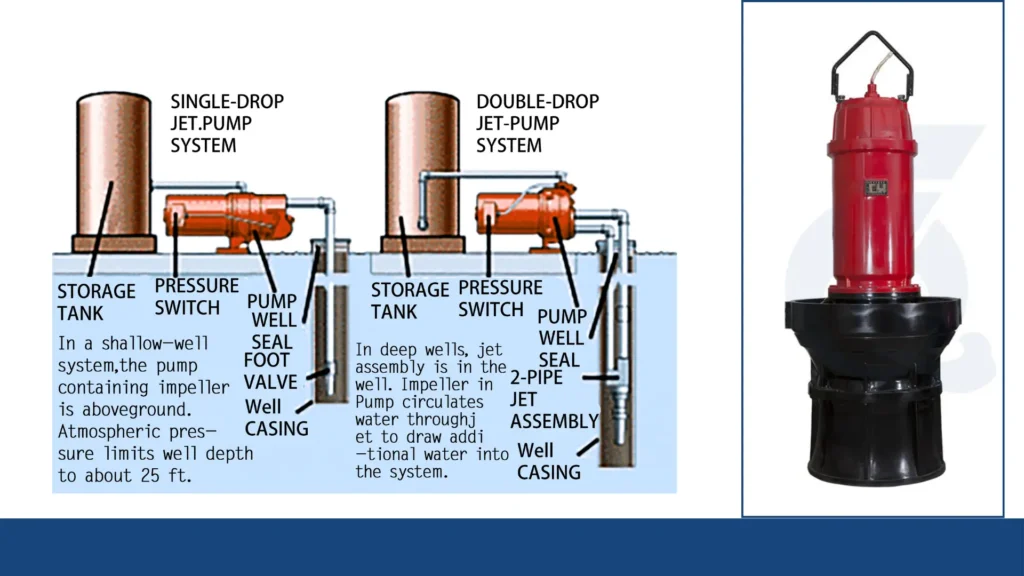

1. They Rely on Hydrostatic Pressure

Submersible pumps leverage the natural water pressure at depth to enhance their pumping capability.

Unlike surface pumps that must create suction to lift water, submerged units work with the existing hydrostatic pressure, significantly reducing energy requirements.

This design allows them to operate more efficiently in deep applications like wells or boreholes, where surface pumps would struggle with suction limitations.

2. They Use Impellers to Move Water

Multi-stage impeller systems generate powerful centrifugal force to propel water upward.

As the motor spins these curved blades, water is flung outward, creating a low-pressure zone that draws more fluid in continuously.

This design eliminates the need for priming and enables consistent flow rates even at considerable depths, making it ideal for continuous operation scenarios.

3. They Are Sealed to Prevent Water Ingress

Hermetic seals and corrosion-resistant materials create a watertight barrier around electrical components.

Specialized mechanical seals prevent leakage at rotating joints, while epoxy coatings protect against electrolytic corrosion.

This robust sealing allows operation in harsh environments, including saltwater, acidic fluids, or abrasive slurry applications.

And More:

- Understanding Submersible Pumps in Fire Protection Engineering

- The Role of Submersible Pumps in Modern Waterworks

Why Does Fluid Mechanics Matter in Pump Performance?

1. Flow Rate Depends on Fluid Dynamics

Pump efficiency directly correlates with fluid behavior principles.

The relationship between velocity and pressure (Bernoulli’s principle) determines how effectively the pump converts rotational energy into fluid movement.

Viscosity changes in different liquids require specific impeller designs to maintain optimal flow rates without excessive energy loss.

2. Pressure Changes Affect Energy Use

The pump must overcome static head pressure (vertical lift) and dynamic losses (pipe friction).

Each additional meter of lift or reduction in pipe diameter increases the pressure differential, demanding more power.

Proper hydraulic design minimizes these losses, with deep-well applications often requiring multistage pumps to distribute the pressure load efficiently.

3. Turbulence Can Reduce Efficiency

Flow separation and vortex formation inside the pump create energy-wasting eddies.

Smooth volute casings and precision-machined impellers maintain laminar flow, while abrupt directional changes or undersized piping cause turbulence that can decrease efficiency by 15-20%.

Computational Fluid Dynamics (CFD) helps optimize modern pump designs for minimal turbulent losses.

What Role Does Centrifugal Force Play?

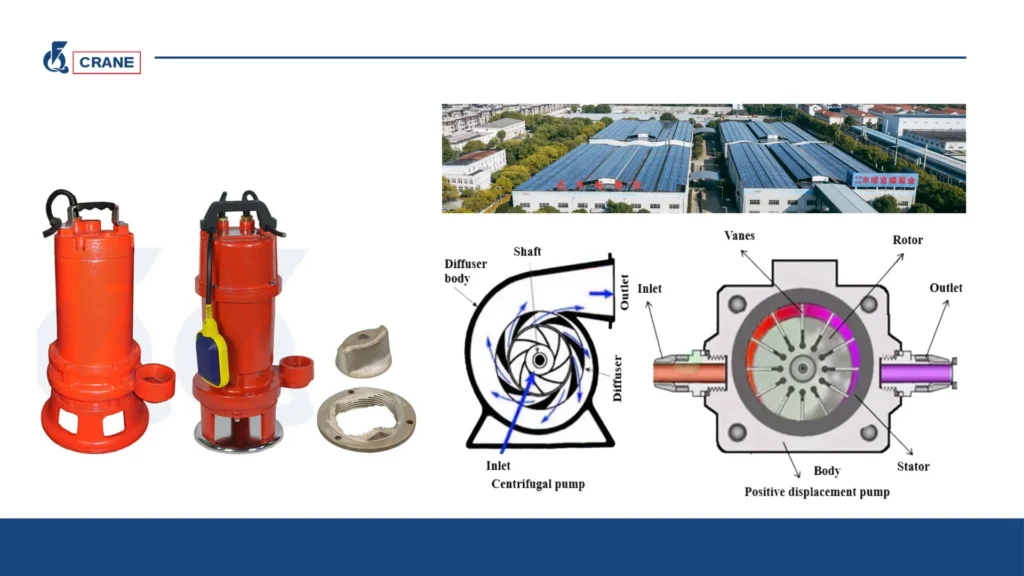

1. It Converts Rotational Energy into Flow

The fundamental operation of centrifugal pumps relies on impellers transforming motor rotation into fluid movement.

As the impeller spins at high speeds, its curved blades accelerate water outward, creating a powerful centrifugal effect.

This action simultaneously generates a vacuum at the impeller’s center, continuously drawing new water into the pump.

The efficiency of this energy conversion directly impacts the pump’s flow rate and overall performance.

2. It Determines Pump Head and Pressure

The relationship between rotational speed and discharge pressure follows the Affinity Laws, where doubling the speed quadruples the pressure output.

This principle allows engineers to select appropriate pump speeds for specific head requirements.

Deep-well applications often use multi-stage designs that sequentially increase pressure through multiple impellers, enabling water delivery from several hundred meters below ground.

3. It Must Be Balanced for Longevity

While centrifugal force enables pump operation, excessive or unbalanced forces cause destructive vibrations.

Precision-balanced impellers distribute rotational forces evenly across bearings and shafts.

Modern pumps incorporate vibration sensors that alert operators to developing imbalances before they cause seal failures or bearing damage, significantly extending service intervals.

Also Read:

- Understanding Submersible Pumps in Fire Protection Engineering

- The Best Submersible Pumps in Agriculture: Ultimate Guide

How Does Water Viscosity Impact Pump Selection?

1. Thicker Fluids Require More Power

Viscous fluids like oil, slurry, or wastewater create substantially more drag than water.

Pumping these materials may demand 30-50% more horsepower to achieve equivalent flow rates.

Manufacturers provide viscosity correction charts to properly size motors, as underpowered units will overheat when handling thick fluids, while oversized pumps waste energy on thin liquids.

2. Impeller Design Must Match Fluid Type

High-viscosity applications use open or recessed impeller designs with larger flow channels to prevent clogging and reduce shear.

These feature fewer vanes (typically 2-3) with greater clearance between the impeller and casing.

Conversely, clean water pumps employ closed impellers with 5-7 tightly spaced vanes for maximum hydraulic efficiency in low-resistance conditions.

3. Temperature Changes Viscosity

Fluid viscosity varies inversely with temperature—a 10°C drop can double a fluid’s resistance to flow.

Seasonal temperature swings significantly affect pumping efficiency, particularly for oils or chemical solutions.

Variable frequency drives help compensate by adjusting pump speed to maintain consistent flow despite viscosity changes, while heating jackets may be necessary for extremely viscous cold-weather operations.

Why Is Pressure a Critical Factor in Submersible Pumps?

1. Depth Increases Hydrostatic Pressure

Every 10 meters of submersion adds approximately 1 bar of pressure the pump must overcome.

In deep-well applications reaching hundreds of meters, this accumulated water weight significantly impacts pump selection.

Manufacturers design specialized deep-well pumps with reinforced housings and multi-stage impellers to handle these extreme pressure conditions while maintaining efficiency.

2. Discharge Pressure Defines Pump Capability

The total dynamic head calculation combines vertical lift, pipe friction losses, and required terminal pressure.

Systems supplying water to elevated storage tanks or pushing through long pipelines need pumps capable of sustaining high pressure throughout the entire operating cycle.

Undersized pumps will fail to deliver adequate flow, while oversized units waste energy and increase wear.

3. Pressure Switches Help Automate Control

These critical components monitor system pressure to activate the pump when pressure drops (indicating demand) and shut it off when reaching preset maximums.

Properly calibrated switches prevent cycling issues, protect against dry running, and maintain consistent system pressure.

Modern digital switches offer adjustable differentials and delay timers for optimized performance.

And More:

- The Best Type of Submersible Pump Depends on Specific Needs

- What Are Common Problems with Submersible Pumps?

Can Fluid Mechanics Explain Common Pump Problems?

1. Cavitation (Bubbles Collapsing Inside the Pump)

When inlet pressure drops too low, water vaporizes forming bubbles that implode violently against metal surfaces.

This phenomenon sounds like gravel flowing through the pump and can erode impellers within hours.

Maintaining adequate submergence depth, proper inlet screen sizing, and avoiding restrictive pipe bends prevents cavitation damage.

2. Water Hammer (Pressure Surges in Pipes)

Rapid valve closures or pump shutdowns convert moving water’s kinetic energy into dangerous pressure spikes.

These shockwaves can exceed ten times normal operating pressure, bursting pipes or damaging fittings.

Solutions include installing surge tanks, soft-start pumps, and slow-closing valves to gradually dissipate energy.

3. Uneven Wear Due to Turbulent Flow

Fluid separation and vortex formation create localized high-velocity zones that erode metal surfaces.

Impeller vanes develop characteristic pitting patterns, while seals fail prematurely from constant abrasive action.

Proper pump sizing, smooth pipe transitions, and avoiding extreme operating ranges promote laminar flow and extend component life.

How Do Pump Manufacturers Use Fluid Mechanics for Better Designs?

1. Computational Fluid Dynamics (CFD) Simulations

Modern pump designers utilize sophisticated CFD software to visualize and analyze fluid behavior before physical prototyping.

These simulations identify turbulence patterns, pressure distributions, and velocity profiles, enabling engineers to refine impeller vane angles, volute geometries, and intake designs.

Virtual testing allows optimization of hydraulic efficiency while minimizing cavitation risks, significantly reducing development time and costs.

2. Streamlined Flow Paths Reduce Friction

Fluid mechanics principles guide the creation of hydraulically efficient water passages.

Gradually expanding volutes convert kinetic energy into pressure more effectively, while precision-machined impeller channels maintain laminar flow.

These improvements can increase pump efficiency by 5-15%, directly translating to energy savings.

Some advanced designs incorporate biomimetic features inspired by natural fluid systems for exceptional flow characteristics.

3. Advanced Materials Resist Erosion

Manufacturers employ fluid dynamics research to select materials that withstand specific flow conditions.

Duplex stainless steels handle corrosive fluids, while tungsten carbide coatings protect high-velocity areas from abrasion.

For seawater applications, super austenitic steels with molybdenum additions resist pitting and crevice corrosion, dramatically extending service intervals in harsh environments.

Also Read:

What Should Buyers Look for Based on Fluid Mechanics Principles?

1. Match Pump Curves to System Requirements

The pump’s performance curve should intersect with the system curve at the desired operating point.

Buyers must account for static head (vertical lift), pipe friction losses, and required flow rates.

Oversized pumps operating far left on their curve waste energy and cause premature wear, while undersized units won’t meet demand.

Professional hydraulic calculations ensure proper selection.

2. Consider Fluid Type and Temperature

Non-Newtonian fluids like sludge require open impeller designs, while high-temperature applications need special seals and expanded metal clearances.

For abrasive slurries, buyers should specify hardened materials and slower operating speeds to reduce particle impact energy.

Fluid viscosity charts help determine necessary power adjustments – some pumps lose 50% efficiency when handling viscous fluids.

3. Prioritize Efficiency Ratings

The best pumps achieve over 85% hydraulic efficiency in their optimal range.

Buyers should compare EU (Energy Utilization) indexes or DOE (Department of Energy) ratings for energy-conscious selection.

Premium efficiency models often pay back their higher initial cost through electricity savings within 2-3 years, especially for continuous operation applications.

Look for independent certification from organizations like Hydraulic Institute.

Conclusion

Fluid mechanics isn’t just for engineers—it’s the hidden science behind every reliable submersible pump.

By understanding how water pressure, viscosity, and flow dynamics affect performance, you can choose a pump that delivers maximum efficiency and durability.

Whether for irrigation, drainage, or industrial use, selecting the right pump based on these principles ensures smoother operation and long-term savings. Invest wisely by thinking like fluid moves!