Submersible pumps are rather vital machines applied in agriculture, at building sites, and in wastewater handling, among other locations.

Such types of water pumps operate under water, and thus they are indeed very efficient for the transfer of water from the bottom of a well or another body of water.

Not all submersible pumps are created equal, however. Knowing what affects their efficiency will prepare you to make a proper choice when buying.

This article seeks to break down the factors that come into play in simple terms to help you make an appropriate choice.

Learn More:

- How to Choose High-Efficiency Submersible Pumps

- 10 Features to Look for in Submersible Pumps

- Steps for Maintaining Submersible Pumps Efficiently

Motor Power

Importance of Motor Size

As power capacity of the motor is generally measured in horsepower, it brings powerful capability of the pump to lift water.

The small-sized motor can’t perform well and is sure to overheat, which causes early burnout of the motor.

On the condition that motor is oversized, an energy waste will happen, which involves high operating costs.

Hence, the selection of a motor for an application corresponding to the requirement of the pump is crucial from the standpoints of efficiency and life.

Energy Efficiency Ratings

Energy efficiency ratings provide some insight into how efficiently a given motor will convert electrical energy into hydraulic energy.

As one might assume, the higher-rated pumps offer operational cost savings and reduced environmental impact.

With a good energy efficiency rating on your pump, you will have savings on your electricity bills and also be helping the world’s sustainability.

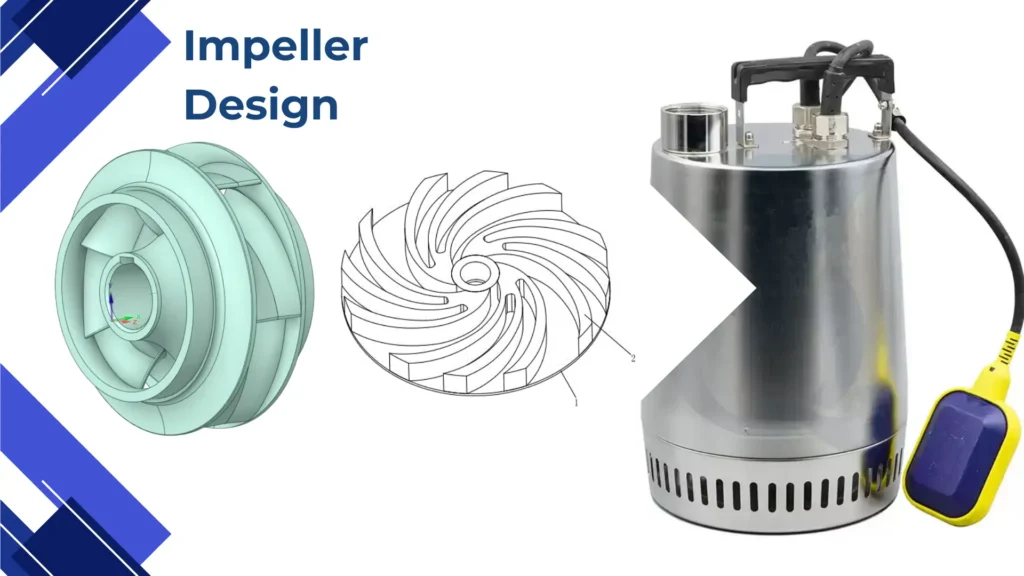

Impeller Design

Types of Impellers

Impeller design is significant in the performance of the pump in its ability to move water.

In different designs, such as centrifugal or screw-type impellers, flow rates and pressure are going to differ.

For example, a higher flow rate is achievable by using a centrifugal-type impeller.

A centrifugal impeller would be one better used when high volumes of water are required.

Conversely, in situations where there is the need to move viscous fluids, a screw-type impeller is more efficient.

Knowing the specific needs of your application helps determine which impeller design you need to accomplish optimal performance.

Material Matters

The material the impeller is made from certainly matters in considering durability and efficiency.

Impellers manufactured from high-quality materials such as stainless steel or reinforced thermoplastics will put up with harsh operating conditions, including abrasive materials and corrosive environments.

If you invest properly in the right pump, which boasts of a well-engineered and rugged impeller, you’re guaranteed to enjoy lower maintenance costs and an extended period of operation, meaning your investment pays off with time.

Product Remmend:

Pump Depth

Submersion Depth

In reality, the depth in which a submersible pump works determines its effectiveness to a great extent.

Pumps used for deeper applications may be designed with heavier-duty motors and additional features that help in maintaining performance at such depths.

In choosing a pump, one must know the greatest depth it will operate in, as it will influence the size of the motor and, of course, the overall design.

A well-specified pump for intended depth will operate more efficiently, therefore saving your time and resources.

Hydraulic Pressure

Operating at deeper levels involves greater hydraulic pressure, which affects the overall efficiency of the pump.

All this increased pressure might result in certain damages and wear to parts, reducing life expectancy.

You need to choose a pump that can really bear the hydraulic conditions for the chosen application.

A high-pressure pump is designed in such a way that it minimizes loss in energy and maximizes overall performance; thus, for deep applications, the investments in such pumps will be well worth it.

Fluid Characteristics

Viscosity

Thicker fluids are harder to pump and bring down the flow rate while overworking the motor.

For instance, it would take a different type of pump for oil or sludge versus that of water.

Knowing the properties of the fluid will lead you to a pump choice that will put up with viscosity levels accordingly for easier operation.

Temperature

Generally speaking, high temperatures weaken the fluids, while low temperatures thicken the fluids, and thus the flow rates may be different. Besides, some materials deteriorate in either high or low temperatures. A pump should be chosen to work under the required temperature ranges of the fluids to be processed in order for it to do the job properly.

Presence of Solids

If the fluid contains solids or debris, the extra wear on the pump parts will result in loss of efficiency and a shortened life span.

Pumps that are designed for use with solids-such as those with vortex impellers or even cutter systems-are best deployed in applications involving dirty water or sewage.

With the right type of pump for the proper application, maintenance requirements can be minimal, and efficiency remains high, even under difficult fluid conditions.

Chemical Compatibility

Construction material for the pump needs to be compatible with the chemicals used in the fluids pumped, lest an incompatible material precipitates corrosion, leaks, or some other failure mode lowering efficiency.

Consult the manufacturer or material compatibility charts to ensure the chosen pump will be able to handle the type of chemicals being used in your application.

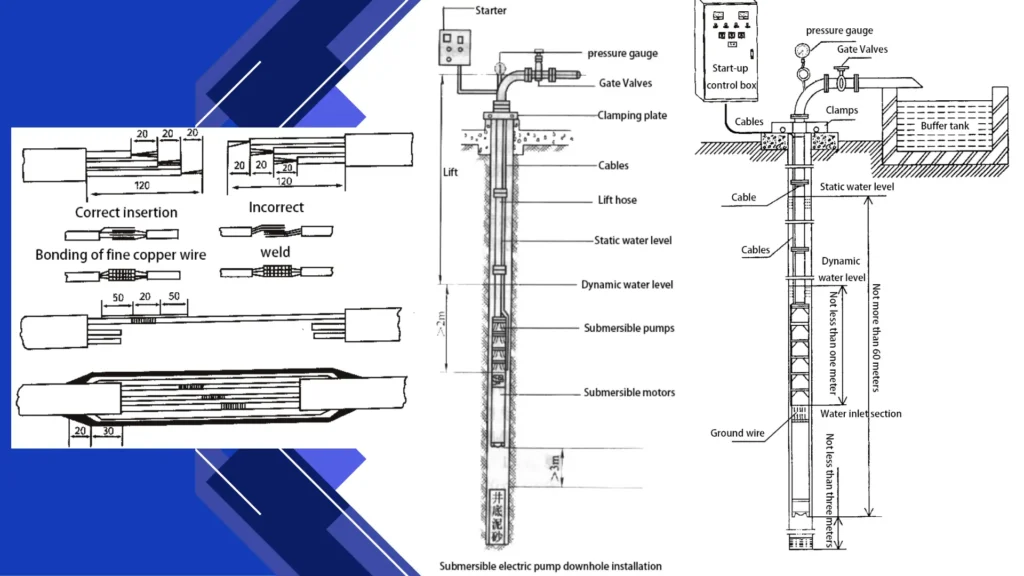

Installation and Maintenance

Proper Installation

Poor installation can cause misalignment, cavitation, and many other issues leading to poor performance.

Installation instructions are strictly to be followed according to the recommendation of the manufacturer.

Proper mounting of the pump and proper depth will ensure maximum efficiency and lifetime.

Periodic Maintenance:

Similar to other mechanical systems, the submersible pump needs periodic maintenance in order to work effectively.

Potential problems that might occur because of wear and tear or blockages should be prevented through routine inspection before they become major issues.

Routine cleaning of filters, seal checks, and lubrication of moving parts will keep the pump in good condition and ensure it provides the best service for many years to its fullest capacity.

Environmental Conditions

Physiology of the Surroundings

The surrounding environment in which a submersible pump exists can effectively determine its efficiency and how long it will last. Some factors that appear to come into play include temperature, humidity, and even exposure to chemicals or corrosive materials.

For example, pumps operating in highly corrosive surroundings may require special coating or material in order for them to be resistant to degradation.

Understanding these environmental considerations will help you select a pump capable of withstanding the particular conditions it will be set to face.

Vibration and Noise Levels

High levels of vibration and noise contribute to operational inefficiency in pumps.

This could be due to improper installation, misalignment, and general component wear and tear.

A selection will be based on a pump designed for quiet running and low vibration for efficiency in the system.

Continuous monitoring of the level of vibration will also indicate the needs for maintenance, well before it leads to severe performance effects.

Flooding/Debris

If an application falls within a flood-prone area or has considerable debris within it, pumps are often designed with features such as protective screens or debris-handling capabilities.

Pumps with the design to handle more substantial solids or excess debris will see less clogging and fewer instances of down times.

The potential for these environmental issues will help in determining the ideal pump that can be used in your application.

Maintenance Access

Another significant factor is related to the ease with which the pump will be accessible for maintenance.

Pumps installed in an inconvenient location may require more and longer service to operate with maximum efficiency.

Normally, a design selection for ease of access will cut time and labor costs later on and thereby enhance efficiency and dependability in general.

Conclusion

Factors affecting the efficiency of submersible pumps should first be known to arrive at wise purchasing decisions.

Your selection can be based on motor power, the configuration of the impeller, pump depth, characteristics of the fluid, and good installation practices in order to arrive at operationally satisfactory and efficient pumps.

Taking pains to study and select the right product will yield long-term dividends in terms of reduced operating costs, better performance, and a reliable pumping solution.