Flood prevention is a critical concern for urban planners, construction managers, and property owners alike.

Among the most essential tools in flood control systems are submersible pumps—durable, high-performance devices designed to move water efficiently even when fully submerged.

This article explores why submersible pumps are indispensable in flood prevention, how they work, and what makes them superior to other pumping solutions—all explained in simple terms for decision-makers and buyers.

What Makes Submersible Pumps Ideal for Flood Control?

Designed to Operate Underwater Without Damage

Submersible pumps feature a robust construction tailored to withstand the rigors of underwater environments.

Their waterproof seals are engineered using high-grade elastomers and gaskets that create an airtight barrier, preventing water ingress into the motor and electrical components.

This is crucial as floodwaters can be highly corrosive, containing salts, chemicals, and contaminants.

High Efficiency with Minimal Energy Waste

The operational mechanism of submersible pumps contributes significantly to their high efficiency.

This direct water-pushing approach eliminates energy losses associated with creating and maintaining a suction head.

There’s no need to overcome air gaps between the pump and the water surface, reducing friction and turbulence.

Compact and Space-Saving Design

The compact nature of submersible pumps makes them highly versatile for flood-prone areas.

Since they are designed to be fully submerged, there’s no requirement for additional external housing or large, bulky structures to accommodate the pump.

This is a significant advantage in confined spaces such as basements, where floor space is already limited, or in underground parking lots and drainage systems where vertical space can be restricted.

Also Read:

- 7 Key Benefits of Submersible Pumps in Water Management

- The Best Type of Submersible Pump Depends on Specific Needs

How Do Submersible Pumps Work in Flood Prevention?

Automatic Activation for Rapid Response

Modern submersible pumps are equipped with advanced activation systems that ensure prompt action during flooding events.

Float switches are a common feature, consisting of a buoyant device attached to a switch mechanism.

Some models use more sophisticated sensors, such as pressure sensors or ultrasonic sensors, which can detect changes in water level or pressure and initiate the pump’s operation.

Handling Large Volumes of Water Quickly

Submersible pumps are engineered with powerful motors and specialized impellers to handle high water flow rates.

The motors are designed to deliver significant horsepower, enabling the pumps to generate the force required to move large volumes of water rapidly.

The impellers, which are the rotating components that push the water, are optimized for efficiency and flow capacity.

Handling Dirty and Debris-Laden Water

Floodwaters rarely consist of clean water; instead, they often carry a variety of debris, including mud, leaves, twigs, small rocks, and even small pieces of plastic or other trash.

Submersible pumps are designed to operate in these challenging conditions.

Their impellers are constructed with wide passages and anti-clogging features, such as non-clogging vanes or vortex designs.

Why Are Submersible Pumps More Reliable Than External Pumps?

No Risk of Overheating

The cooling mechanism of submersible pumps sets them apart from external pumps when it comes to preventing overheating.

Submersible pumps are surrounded by water during operation, and this water acts as a natural coolant.

As the pump’s motor and other components generate heat, the surrounding water efficiently absorbs and dissipates this heat, maintaining a stable operating temperature even during extended periods of use.

Reduced Noise and Vibration

The underwater operation of submersible pumps provides significant advantages in terms of noise and vibration reduction.

This natural sound insulation makes submersible pumps extremely quiet in operation.

In residential areas, where noise pollution can be a major concern, the quiet operation of submersible pumps ensures that homeowners are not disturbed during floodwater removal.

Longer Lifespan with Less Maintenance

Submersible pumps are built with durability in mind, resulting in a longer lifespan and reduced maintenance requirements compared to external pumps.

Their sealed motors are designed to prevent water and debris from entering, protecting the internal components from damage and wear.

These design features minimize the likelihood of breakdowns and malfunctions.

And More:

- Understanding Submersible Pumps in Fire Protection Engineering

- Role of Submersible Pumps in Municipal Applications

Where Are Submersible Pumps Most Commonly Used in Flood Prevention?

Residential Basements and Underground Structures

Many homes with basements or underground storage areas are at risk of water intrusion during heavy rains, melting snow, or plumbing failures.

Submersible pumps play a crucial role in protecting these structures.

Sump pumps, a type of submersible pump, are commonly installed in sump pits located in the lowest part of the basement.

When water accumulates in the sump pit, the float switch on the submersible pump activates, and the pump starts removing the water, preventing it from rising and causing damage to stored items, electrical systems, and the building’s foundation.

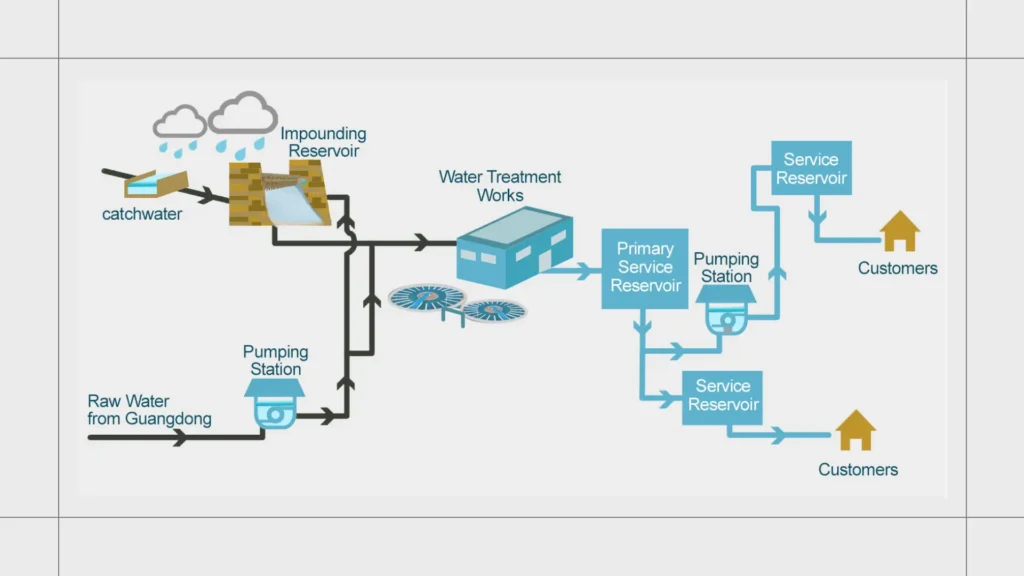

Municipal Drainage and Sewage Systems

Cities face significant challenges in managing stormwater and preventing urban flooding.

Submersible pumps are essential components of municipal drainage and sewage systems.

Large-scale submersible pumps are installed in pump stations located throughout the city, particularly in low-lying areas and areas prone to flooding.

These pumps are designed to handle high volumes of water and can operate continuously during heavy rainfall events.

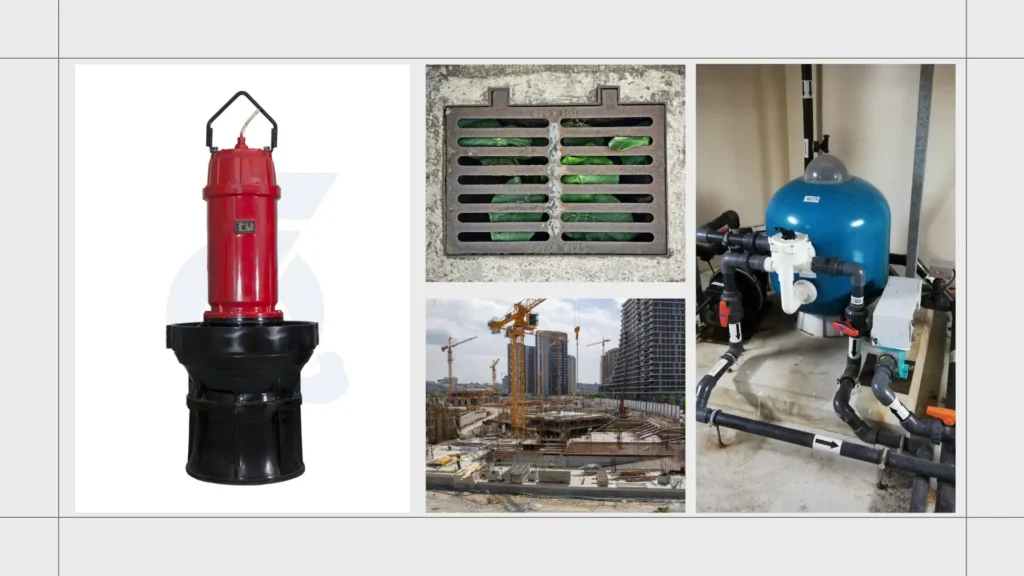

Industrial Sites and Construction Pits

Industrial sites and construction projects often encounter issues with water accumulation, which can disrupt operations and damage equipment.

Submersible pumps are widely used in these settings to keep work areas dry. In industrial facilities, submersible pumps can be used to remove water from sumps, trenches, and other low-lying areas where water may collect.

They are also used in cooling systems to circulate water and maintain proper operating temperatures for machinery.

What Features Should You Look for in a Flood Prevention Pump?

High Flow Rate for Fast Water Removal

The flow rate of a flood prevention pump is a critical factor that directly impacts its effectiveness in minimizing flood damage.

Measured in gallons per hour (GPH), this metric indicates the volume of water a pump can displace within a specific time frame.

During a flood, every minute counts, and a pump with a higher flow rate can remove water from affected areas more rapidly.

Durable Construction for Harsh Conditions

Floodwaters often contain a variety of debris, including mud, leaves, twigs, and small rocks, which can put significant stress on a pump’s components.

To ensure a flood prevention pump can withstand these harsh conditions and provide long-term reliability, it’s crucial to look for models with durable construction.

Stainless steel and cast-iron housings offer excellent resistance to corrosion and physical damage.

Automatic Controls for Hands-Free Operation

In emergency flood situations, manual operation of a pump may not be practical or even possible.

Automatic controls, such as float switches, digital sensors, and remote monitoring capabilities, offer significant advantages.

Float switches are a common and reliable feature. They consist of a buoyant device attached to a switch mechanism.

As the water level rises, the float lifts, triggering the switch and activating the pump. This ensures that the pump starts removing water as soon as it reaches a certain level, without the need for manual intervention.

Also Read:

- Design and Optimization of Efficient Flood Control Pump Systems

- The Best Type of Submersible Pump Depends on Specific Needs

How Do Submersible Pumps Compare to Other Flood Control Solutions?

More Efficient Than Pedestal Pumps

Pedestal pumps and submersible pumps have distinct operational differences that impact their efficiency in flood control.

Pedestal pumps are designed to sit above the water, with only the pump’s intake pipe submerged. They rely on suction to draw water into the pump, which can create several challenges.

The suction-based operation limits the depth from which they can effectively draw water, and they are more prone to airlock issues.

More Compact Than Centrifugal Pumps

Centrifugal pumps and submersible pumps differ in their installation requirements and space utilization.

Centrifugal pumps typically require separate installation space, including a dedicated pump house or enclosure to protect the pump and its components.

They also need extensive piping systems to connect the pump to the water source and the discharge point. This setup not only takes up a significant amount of space but also increases the complexity and cost of installation.

Better for Deep Water Than Sump Pumps

While sump pumps are effective for handling shallow water in residential basements and similar settings, submersible pumps have distinct advantages when it comes to operating in deeper water.

Sump pumps are typically designed for relatively shallow water depths, usually within the range of a few feet. They are optimized for removing water that accumulates in sump pits, which are often located in the lowest part of a basement.

When the water level in the sump pit reaches a certain point, the sump pump activates and pumps the water out.

What Maintenance Do Submersible Pumps Require?

Regular Cleaning to Prevent Clogs

Floodwaters and other water sources where submersible pumps operate often contain various debris, such as leaves, twigs, dirt, and small pieces of plastic.

Regular cleaning is essential to keep the pump in optimal working condition, especially in preparation for potential flood emergencies.

Homeowners or facility managers should inspect the pump intake at least once a month, or more frequently in areas prone to debris buildup.

Periodic Seal and Cable Checks

The waterproof seals and electrical connections of submersible pumps are crucial components that ensure safe and reliable operation.

To prevent leaks and power failures, it’s recommended to conduct annual checks of these elements.

During the inspection, technicians will carefully examine the seals for any signs of cracking, swelling, or leakage.

Motor and Impeller Inspections

The motor and impeller are the heart of a submersible pump, and their proper functioning is vital for efficient water pumping.

Over time, the motor can experience wear on its bearings, brushes, and other internal components due to continuous operation and exposure to water.

The impeller, responsible for pushing water, can also suffer from abrasion and erosion caused by debris in the water.

And More:

- What is the Process For Cleaning a Stainless Steel Submersible Pump?

- Common Maintenance Tasks for Submersible Pumps

Are Submersible Pumps a Cost-Effective Flood Prevention Solution?

Higher Initial Cost but Lower Long-Term Expenses

Submersible pumps generally come with a higher upfront cost compared to some other types of pumps, such as basic pedestal pumps.

This is due to their specialized design, which includes waterproof seals, corrosion-resistant materials, and powerful motors.

Submersible pumps can remove water more quickly with less energy waste, resulting in lower electricity bills over the years.

Preventing Expensive Water Damage

The cost of water damage from a single flood can be astronomical. Floodwaters can ruin furniture, electronics, and building materials, and the subsequent repairs can run into the thousands or even tens of thousands of dollars.

A reliable submersible pump acts as an insurance policy against such losses.

By quickly removing floodwater, it minimizes the time that water has to penetrate structures and damage contents.

Customizable Options for Different Budgets

Submersible pumps come in a wide range of models and specifications, making them suitable for various budgets and needs.

For homeowners on a tight budget, there are basic residential models available that offer reliable flood prevention at an affordable price.

These pumps typically have lower flow rates but are sufficient for protecting small basements or crawl spaces from occasional flooding.

Conclusion

Submersible pumps play a vital role in flood prevention by offering fast, efficient, and reliable water removal in various settings. Their ability to operate underwater, handle debris, and work automatically makes them superior to many traditional pumping solutions.

For property owners, city planners, and construction managers, investing in a quality submersible pump means better flood protection, lower maintenance costs, and peace of mind during extreme weather.

If you’re considering flood prevention solutions, a submersible pump could be the most effective choice for your needs.