Submersible pumps find wide-ranging applications, starting from sewers, mining, and farming to many more.

These pumps have a sealed motor driving an impeller, which creates pressure to push the liquid to the surface.

Their design allows the pump to be directly placed into the fluid it is moving, reducing the risk of cavitation-a phenomenon that has been known to destroy other types of pumps.

Compared to other pump types, the submersible pumps have quite impressive advantages.

Their compact design economizes on space and is therefore ideal for tight installations.

Besides, they cause less noise during their operation and are, therefore, mainly useful in residential areas or such sensitive environments.

Learn More:

- 6 Applications of High-Efficiency Submersible Pumps

- What is a Submersible Pump Used For?

- The Ultimate Guide to Industrial Submersible Pumps

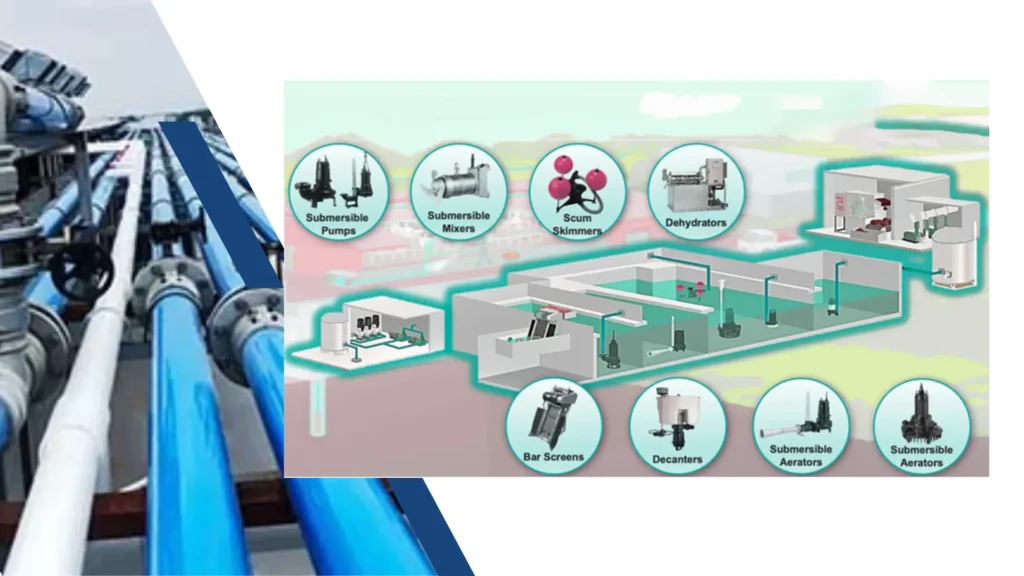

Use of Submersible Pumps in Wastewater Treatment

Role of Submersible Pumps in Wastewater Transport

Their main purpose in water treatment plants is to pump sewage and stormwater from collection points to the treatment plants.

Design-wise, they are made to handle both liquid and solid wastes, thus their wide applications in municipal service.

Submersion enables the pumping of the fluid right from its source, thus simplifying the system and reducing clogging hazards.

Efficiency and Reliability

These are designed to be reliable, work without stoppage in harsh conditions.

The efficiency creates savings on energy and minimizes any chance of breakdowns for smoother operations of wastewater treatment plants.

The application of submersible pumps ensures the processing of wastewater in as short a time as possible to help avoid further environmental contamination and public health problems.

Submersible Pumps in Mining Operations

Dewatering in Mining

The amassed water in mines may present them with hazardous conditions and include further risk of flooding and instability.

Submersible pumps remove excess water with much greater efficiency, thus enabling miners to work safely and effectively.

Benefits in Harsh Environments

Mining environments often impose extreme conditions, such as high pressure and abrasive materials.

Submersible pumps are designed to address these issues with strong materials and designs that ensure longevity and reliability.

Agricultural Applications for Submersible Pumps

Irrigation and Drainage

Diverse Agricultural Applications

Submersible pumps can be utilized in several different agricultural applications, primarily in irrigation and drainage.

They can extract water directly from deep wells or surface water bodies and deliver it efficiently at the actual sites of crop hydration.

This is particularly useful in arid regions where every drop of water counts in the successful growth of farming.

Growth Sustainability for Arid Regions

In the submersible pumps, they play an important role in the crop-watering purpose for its maturity and growth in semi-arid regions due to the scarcity of natural rainfall.

Farmers are able to maintain healthy crops through the dependable and continuous supplies provided by such a pump.

Besides, their capability for working at variable depths enables flexibility in the irrigation methodologies; hence, they have become one of the important tools for contemporary agricultural activity.

Impact on Crop Yield

Submersible pumps make a big difference in crop yield since they provide regular water supply.

This form of pump empowers farmers to employ good irrigation practices that keep the plants healthy and increase their productivity.

In addition, submersible pumps promote the conservation of water since farmers are able to adopt irrigation in specific lots and at specific times, which shows positive feedback for sustainable farming in regard to eco-balance as well as agronomic economy.

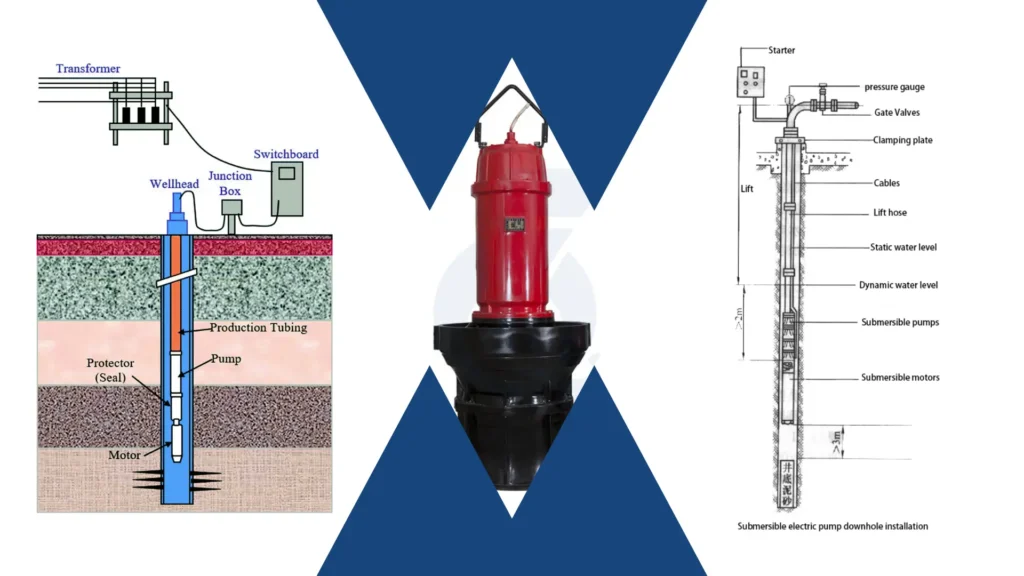

Submersible Pumps in Oil and Gas Industry

Extracting Oil and Gas

Vital for Resource Extraction

One of the most vital uses of submersible pumps is in the oil and gas industries for extracting such resources from deep deposits underground.

These are specially designed to function under very high pressures, something quite essential in the extraction of resources lying deep beneath the surface of the Earth.

With a heavy structural design, they can handle viscous fluid quite efficiently, commonly found in the extraction processes relating to oil.

Smoothing Efficiency and Profitability

The nature of this generally hostile environment is such that extraction processes, when assisted by submersible pumps, are bound to be very efficient and economic.

This is because of the minimization of energy consumption and high outputs, and these pumps play a huge role in improving the profitability of oil and gas operations.

Operating faultlessly at amazing depths, they realize not only the benefits of operational efficiency but also assist companies in meeting the increasing demand for energy resources within the competitive frontier of the market.

Challenges and Innovations

Special challenges are embedded in the oil and gas industry, such as a corrosive environment and extremely reliable operation. Investments in innovative technologies of advanced materials resistant to corrosion and smart monitoring systems for improvement of pump performance will resolve the above-mentioned issues and improve operational efficiency with prolonged lifetime in challenging operation conditions.

Marine and Offshore Applications

Application in Marine Environments

The submersible pump has become indispensable in marine applications, especially in ship ballast systems, which maintain stability and safety during voyages.

These pumps circulate water to and from ballast tanks to keep ships correctly balanced-a matter of paramount importance for successful safe navigation.

Corrosion Resistance and Durability

The conditions are very harsh for the pumps, such as saltwater and high humidity, which easily result in rapid corrosion.

Submersible pumps developed for these environments are made using materials that are resistant to corrosion and are robust in nature to withstand such operations.

Their durability is, therefore, crucial in ensuring that operations efficiency is maintained while offering reduced chances of downtime in such offshore settings.

Advantages of Submersible Pumps

Key Benefits

Submersible pumps have many advantageous features that put them in very high demand in many industries.

As a rule, they are energy-saving and consume less power compared to standard pumps.

Thus, such efficiency allows the reduction of operational costs and decreasing ecological impact.

Comparison with Other Solutions

Submersible pumps have a slim body build compared to other pumping solutions, hence ideal for space applications with no performance compromise.

Equally, they are relatively noise-free compared to others, hence comfortable in residential areas or sensitive environments, which acts as an advantage in many uses.

Challenges and Considerations

Potential Challenges

In spite of such advantages, submersible pumps have their challenges which they throw on the users.

For instance, maintenance would more often than not be complex since it deals with operation underwater. Inappropriate installation is related to performance problems.

Certainly, users have to make sure that they follow the manufacturer’s instructions in order to avoid certain problems.

Choosing the Correct Type of Pump

The choice of the correct submersible pump, therefore, largely depends on the type of fluid to be transferred, depth at which the operation is to be carried out, and flow rate desired.

Such a pump can be selected after thorough research and expert advice in order to make sure that it will serve the particular requirements of the application to realize maximum efficiency and durability.

Product Recommend:

Future Trends in Submersible Pump Technology

Technological Advancement

The integration of smart technology into the core of this coming-of-age submersible pump industry is fast in order to enable real-time monitoring and control.

Innovations in materials science have created pumps that can resist corrosion and wear more strongly, increasing their durability and lifespan.

Prediction for the Future

With expectations set high for further innovations that shall see improvements in their effectiveness and expansion of their areas of application, the future of submersible pumps looks bright.

At this point, when most industries are after greener and more workable solutions, the demand for better technologies in pumping in the various industries shall rise, increasing the importance of submersible pumps in modern operations.

Conclusion

Submersible pumps play a vital role in many industries where dependability and effectiveness in fluid transportation is required.

Because of their versatility, they are irreplaceable, from wastewater treatment to agriculture to oil extraction.

As technology continues to evolve, so does the importance of a submersible pump, continuing to grow and further solidify its key role in making sure things run smoothly and efficiently in all sorts of different industries.

Understanding their uses and advantages better will, in turn, enable businesses to make wiser decisions that use these powerful tools for enhanced performance and sustainability.