From groundwater extraction to sewage and flood management, these valuable devices serve so many purposes in various waterworks.

The correct selection of a submersible pump is your only ticket to getting the absolute best with regards to both efficiency and reliability from your water management systems.

All incorrect selections can cause many problems; excess energy consumption, increased breakdown, and insufficiently adequate water flow would upset operations and cost accordingly.

We want to make the basic and application data in clear and accessible form so that you can do a better job in making the decisions that best suit your particular water management requirements.

Learn more:

Understanding Submersible Pumps

Submersible Pumps Used in Waterworks

Submersible pumps come in different types for specific uses:

Clean Water Pumps

Suitable for draining cellars, or even swimming pools, these pumps are designed to handle clean water free from debris.

Sewage Pumps

These pumps can handle solids and wastewater; hence, this type of pump is considered essential in the municipal sewage system and residential areas because they effectively mobilize the wastes.

Deep Well Pumps

These pumps are designed to draw water from deep underground supplies and are deemed indispensable in irrigation farming and in the municipal supply of water.

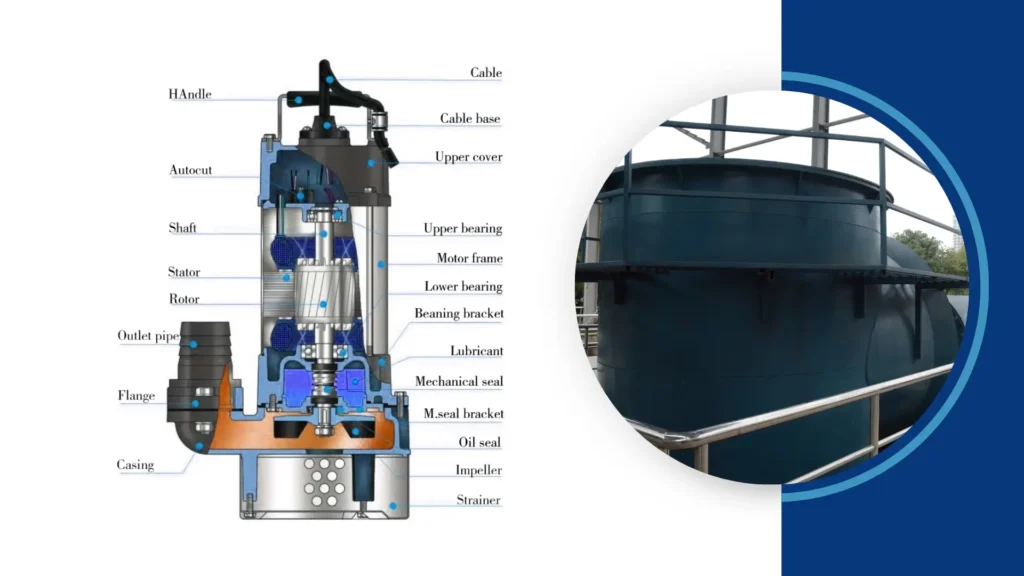

Important Components and Their Functions

For the performance evaluation of the submersible pump, necessary understanding would be the component description of the pump:

Impeller

The impeller forms the heart of the pump-rotating to cause a difference in pressure that advances water through the pump.

Motor

Usually located above the impeller, the motor serves to drive the impeller and is often sealed to prevent water from reaching it.

Seal

A very key component in avoiding even the remotest possibility of water coming into contact with the motor allows the pump to carry out its intended function.

Product Remmend:

Assessing Water Requirements

Volume of Water to Be Pumped

Before placing an order for a pump, you need to pre-calculate the volume of water that you intend to shift.

This is by checking the requirement on a daily or hourly basis; consumption may differ at different times of the day.

For instance, if it’s irrigation, you take into consideration the area to be irrigated and the amount of water required per square meter.

Understand Depth and Distance of Water Source

Some of the key factors to consider in the selection include the head or depth of the water and the length of distance through which the water must be pumped.

The deeper the source of water, the higher the head pressure the pump should have, whereas longer distances require a motor with more power to allow for friction losses in the piping.

Application Needs Assessment

Applications vary in needs specific to:

Draining

It needs higher flow rates in order to withdraw extra water as soon as possible.

Irrigation

However, pumps designed for irrigation must be able to run efficiently across a wide range of levels of water and consistent flow rates.

Sewage

The sewage pumps have to be powerful enough to manage solid and debris movements without failing and clogging up.

Key Specifications to Consider

Flow Rate and Head Pressure

A pump’s flow rate defines the quantity of water a pump can deal with within a specific period, while head pressure is the term used for defining how high a pump can move the water.

Both these specifications are crucial for the right assessment whether the pump is capable of meeting your requirements in your particular application.

Power Source and Energy Efficiency

Consider the power input for your pump: electric, which is more applicable in residential and municipal applications, or diesel, more suitable for remote locations.

Energy efficiency is another important factor, since higher efficiency means a lot of savings in electricity bills over time.

Material and Construction Quality to Last

The pumps made of higher quality raw materials such as stainless steel or reinforced thermoplastics will have a superior span of performance and hostile environment tolerance.

The construction quality is something quite vital, and even urgent, for pumps working with corrosive substances.

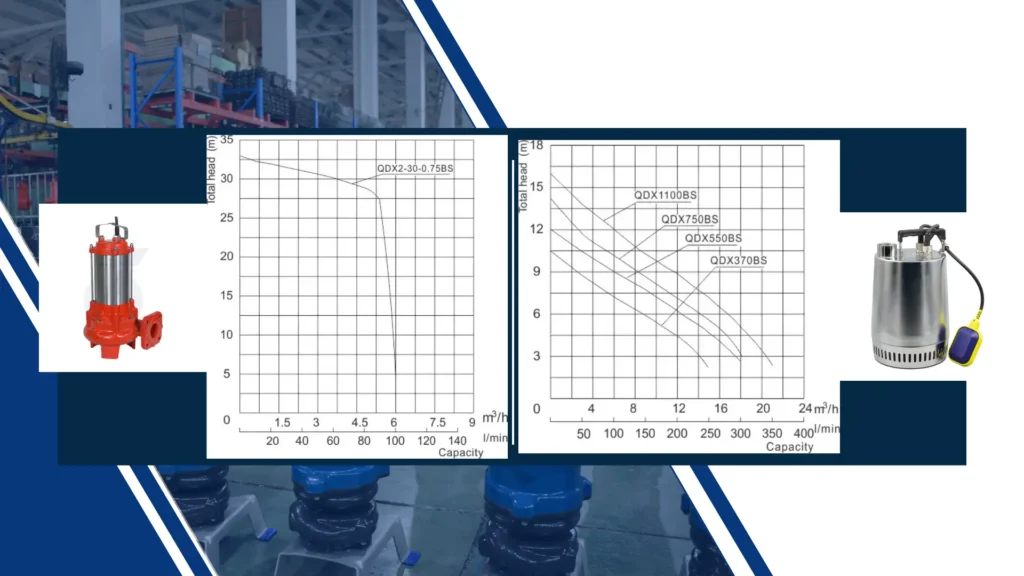

Evaluating Pump Performance

Pump Curves and Performance Charts

Pump curves are graphic representations showing how a particular pump will perform over a series of flow rates and head pressures.

Gaining knowledge of these curves will allow you to choose a pump that effectively operates within your parameters.

Efficiency Factors Affecting Pumps

A number of factors may affect pump efficiency, including the following:

Impeller Design

The shape and size of the impeller can greatly affect the performance of the pumping of water.

System Resistance

The design of the piping system, possibly containing bends and fittings, increases the resistance and further decreases efficiency overall.

Common Performance Metrics to Analyze

In regards to pumps, some of the key metrics one should consider include:

Efficiency Rating

This percentage describes how well the pump transfers the energy input into hydraulic energy.

Total Dynamic Head (TDH)

The total height the pump needs to pump the water while considering friction losses in the piping system.

Maintenance and Longevity

How Regular Maintenance of Submersible Pump Impacts Its Operation

Regular maintenance is essential to make your pump work in the best possible manner for the longest period.

The routine inspection will cause small problems not to develop into serious repairs, saving you considerable time and money.

Signs of Wear and Issues to Watch

Look for warning signs such as unusual sounds, vibrations, or a drop in water production.

Such symptoms may testify to wear and potential problems that should be taken care of straight away.

How to Prolong the Life of the Pump

To get the most out of the life of your submersible pump, here are some good practices you can use:

Routine Cleaning

Remove dirt and sediment deposits which may clog the pump and reduce its capacity.

Electrical Checks

All electrical connections must be tightly fitted and operational; this helps prevent electrical failure.

Budget Considerations

Cost-Effectiveness and Return on Investment Analysis

Testing the total cost of ownership will help you establish if a certain pump is cost-effective or not.

You need to seek out those models that balance relatively low initial investment with ongoing operational savings.

Long-Term Financing Options for Large Projects

In large-scale projects of a waterworks, one can look into long-term financing options which can spread over time and not strain your budget from investing in a high-quality pump.

Manufacturer Reputation and Support

Selecting Reputable Manufacturers

Pumps from well-reputed companies will instill a sense of assurance, since such firms are often built on a history of consistent performance and quality.

Renowned brands are more likely to sell quality products with better and more reliable warranties.

Consideration of After-sales Service and Warranty Available

Assess the after-sales support and warranty service from the manufacturers themselves.

A good warranty will protect your investment, but attentive customer service may be your safe haven if things do go wrong.

Reviewing Customer Reviews and Testimonials

Research reviews and testimonials of customers of a particular pump that you intend to buy.

The feedback will come in handy in informing you what usually goes right or wrong with any particular pumps and the reliability of the manufacturer.

Conclusion

Choosing an appropriate submersible pump for the desired waterworks application is a significant decision and may be the factor whether the transfer is economically viable, efficient, or dependable.

Understand the different types of pumps that exist and begin to evaluate your needs.

Using that experience, make a considered choice for a pump type to best serve you in the long run.

Keep in mind that in investments such as this, it is always important to get quality; maybe reputed manufacturers will come up with good results.