Submersible pumps are a cornerstone in a lot of industries; these industries range from dewatering and irrigation to wastewater management.

Here is a short tutorial on how one effectively maintains submersible pumps.

Routine inspections, cleaning techniques, and troubleshooting-melded together-form ways to extend the life of your pump and cut down on potential repairs.

The following simple maintenance routines will help in keeping your submersible pump in excellent condition.

Inspect the Pump Regularly

Look for Signs of Damage

Several visible signals include cracks, dents, or corrosions on the casing of the pump, which could show signs of wear and tear.

These should be addressed immediately to avoid larger issues later on.

Inspect the Casing of the Pump

It should be intact, not showing any physical damage. Physical damage leads to leakage and eventual inefficiency.

This is a factor that will displease the overall performance of your pump.

Cleaning it regularly may also help save it from corrosion, hence allowing it to work for a longer period.

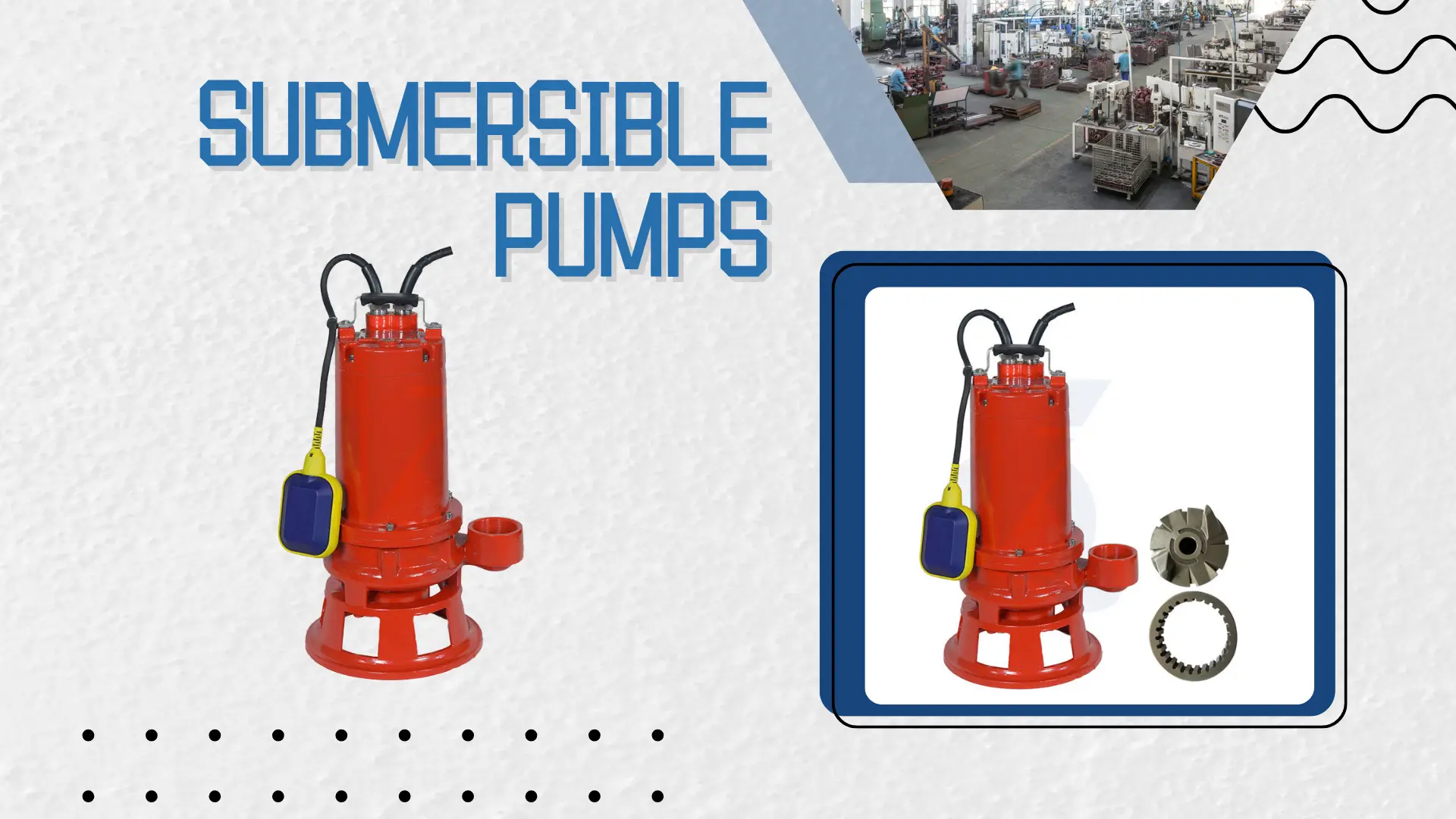

Check the Impeller and Wear Rings

The ring and the impeller are to be inspected for wear or any other damages; once a slight damage is seen, the flow rates will be grossly affected.

Worn-out parts must be replaced to give the pump its efficiency once again.

Test the Electrical Components

The electrical parts are the most crucial parts of the pump. In that case, some periodic tests will prevent it from sudden failure.

Testing of Motor Windings

Motor windings check continuity with a multimeter. Any unusual reading will detect the problem to be fixed immediately.

This check on winding will ensure that the pump is reliable.

Check for Proper Grounding

Poor grounding can lead to electrical hazards, which means the pump will be prone to electrical shock.

A well-grounded pump minimizes the occurrence of electrical shock hence boosting safety both to the operators and the environment.

Regular checks help avoid any form of electrical malfunctions that may lead to very expensive downtime.

Perform Preventative Maintenance

Change the Pump Oil

Regular changing of the pump oil is one of the key factors in lubrication and prevention of overheating.

Fresh oil ensures that the operation of the internal components is smooth, hence reducing friction and wear.

Drain and Refill the Oil Reservoir

This helps in maintaining the best lubrication and hence health of the pump’s motor to extend its life expectancy.

Record the intervals for changing the oil to maintain performance effectively.

Disposal of Used Oil Appropriately

Proper disposal is not only environmentally correct but serves to keep your area of work safe, as well as prevent any potential pollution or contamination.

You might want to avail yourself of a recycling facility that handles this type of waste so that you are meeting the legal requirements of your jurisdiction.

Clean the Inside of the Pump

Cleaning the inside of the pump is absolutely required for peak performance.

Scrape away build-up and debris.

Deposited material could be obstructing the flow and creating more losses.

A clean interior can allow the pump to achieve full performance and, more importantly, the pump can meet your operational requirements.

Clean the Pump Chamber with a Disinfectant

Periodic disinfection of the pump chamber can prevent bacterial growth and maintain water quality, especially in irrigation or potable water applications.

A proactive measure that enhances your pumping operation in terms of safety and effectiveness.

Apply the appropriate disinfectants safely for their intended use and per application guidelines.

Read More:

- How to Choose High-Efficiency Submersible Pumps

- 10 Features to Look for in Submersible Pumps

- How to Optimize Performance of Submersible Pumps

Monitor Pump Performance

Operating Temperature Tracking

Monitoring operating temperature may allow early detection of an upcoming problem before it becomes a serious condition.

Detect Any Anomalies of Heating

If you observe any abnormal temperature build-up, that would signify a problem with either the motor or bearings inside the pump.

Let this be an immediate cause for investigation to prevent further damage and ensure the continued effectiveness of your pump.

Overheating Issues Should be Addressed without Delays

That may involve checking for blockages or ensuring that the pump is suitably lubricated.

It may save you from costly repairs and prolong the life of your machinery.

You can install temperature sensors to automate this monitoring process and alert you on time in case anything goes out of order.

Measure Flow Rates and Pressure

Regular measurement of flow rates and pressure will keep your pump within the specifications set by the manufacturer.

Performance Tracking against Manufacturer Specification

Log performance of your pump, then compare it against the manufacturer’s specifications.

Knowing these benchmarks will enable you to determine whether there is something that is not right and that should be fixed in order to keep up the continuing operation.

This can also show improvement or decline in performance over time.

Troubleshooting Declining Performance

If its performance is not right, it tries to find the fault and correct it. It may be due to blocked chokes or electrical connections or even the internal parts.

Early detection and correction of problems will avoid major issues in the future and keep your pump working as per requirements.

Schedule Regular Inspections

Design a Maintenance Schedule

It is very necessary to prepare a maintenance schedule for your pump so that it continues to function well.

Weekly, Monthly, and Yearly Checkups

Small problems caught through weekly, monthly, and yearly inspections prevent minor issues from evolving into larger ones.

By periodic scheduling based on use, you increase the dependability.

Record Maintenance Performed

Such a record can be very useful in tracking, over time, the performance of the pump and can be invaluable for future repairs, giving a clear history of your pump’s care.

Employ a Professional Service Provider

Where the problem may be complicated, it may be beneficial to seek service from a professional service provider.

Tap Knowledge for Complicated Problems

Professionals bring expertise to help diagnose problems that might be occurring, which may not be immediately apparent, and fix them.

Their experience will save time and money in the long run by making sure that your pump is operating correctly.

Routine visit and consultation from a professional may also give one an overview of the changing best practices and emerging technologies.

Use Proper Parts and Tools

This will not only improve efficiency while reducing post-repair issues but also help in enhancing the life cycle of your pump to save you from business downtime.

The compatibility and reliability you will be able to achieve by using OEM parts.

Conclusion

Through these actual steps, such as routine checkups, preventive maintenance, monitoring performance, and routine checkup scheduling, a pump should be able to enjoy efficiency and longevity for many years.

If well taken care of, you will be assured of the highest level of effectiveness from your submersible pump rather than taking chances with expensive repairs. Make maintenance your priority, and enjoy the benefits of a dependable and effective pumping solution.

These practices will pay for themselves in improved performance and longevity, eventually providing easier and more economical operations.