Unlike all the traditional pumps that sit above the liquid surface, these submersible pumps are designed to face complete submergence and allow the effective transportation of fluids from one point to another with efficiency.

Their normal construction includes a hermetically sealed motor that does not allow water to enter inside the motor; hence, they ensure good service in demanding environments.

Their capability for managing a substantial volume of liquid at great velocity secures efficiency in production.

Furthermore, these pumps have been designed to operate nonstop to minimize production downtime and further increase this industry’s productivity, where consistency and speed are two of the major keys.

This blog post is a general and understandable overview of industrial submersible pumps and will cover their importance, particular design specifications and new technological developments for food and beverage industries.

Learn More:

- The Ultimate Guide to Industrial Submersible Pumps

- Promotional Article on Sewage and Wastewater Submersible Pumps

Hygienic Design and Sanitary Standards

Explanation of  Hygienic Design Principles

Hygienic Design Principles

Hygienic design is a common aspect in most food and beverage industries for equipment use.

It encompasses principles that reduce the chances of contamination, ensuring the products are harmless to consumers.

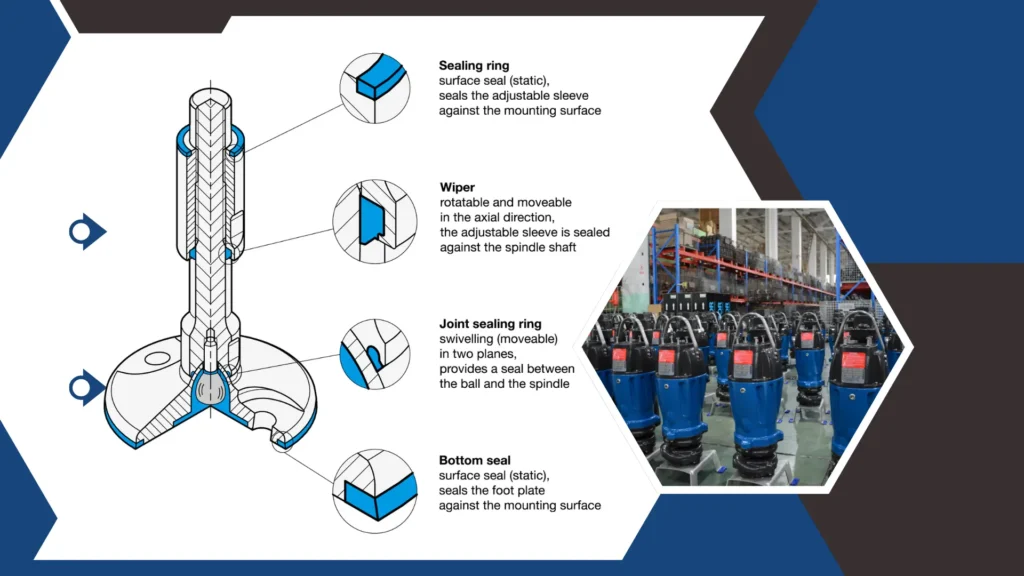

Submersible pumps should be of smooth-surfaced nature devoid of crevices where bacteria may colonize.

Overview of Relevant Sanitary Standards and Regulations

Food manufacturers are compelled to follow sanitary standards within the food industry.

These kinds of standards would consider those by the FDA and the NSF on specifications regarding materials, design, and maintenance an equipment requires to work safely within the production chain.

Pumps can be manufactured from only food-grade material and should be designed with cleanliness consideration in mind to prevent any possibility of contamination during the production process.

Handling Different Types of Food Products

Type of Various Food Products

Food products can vary over a wide range of physical properties, from thin, watery liquids to thick, viscous sauces and dressings. Some products may contain solid particles-pulp in fruits or grains.

This understanding of the product is important in pump selection since different pumps are designed to handle more or less viscosity and solid contents.

Submersible Pumps’ Adaptability to Various Applications

The most salient advantages of a submersible pump are their versatility.

They can be made for very different applications within the food and beverage industry, adapting to the different needs of a variety of products.

Some of the submersible pumps have adjustable speeds, enabling them to handle thin liquids at one point in time and thicker pastes at another with equal efficiency, thus optimizing the production process as a whole.

Case Studies of Successful Implementations

Scores of firms have been able to put submersible pumps to work profitably. For example, a major juice manufacturing customer was experiencing pulp and juice transfer issues.

This was causing loss in the form of additional waste and sapping of efficiency.

For this client, top-of-the-line submersible pumps replaced the existing ones within the firm and significantly improved liquid transfer-which meant minimal waste and a general boost to productivity.

Examples like these demonstrate how investment in appropriate pumping solutions has reaped quantifiable dividends.

Temperature and Pressure Requirements

Introduction to Temperature and Pressure Demands in Food Processing

The applications within food processing come into being under extreme conditions, taking into consideration the high temperatures which are necessary at the pasteurization process and changing pressures along the production line.

Knowledge of these conditions is important during the selection of appropriate pumps that have the ability to work under these conditions without failing or worse still, damage.

Selection of Pumps That Meet These Requirements

Selection of pumps according to temperature and pressure ratings is vital for operational reliability.

Pump incompatibility with the operating conditions specified will lead to mechanical failure from regular operation, which may result in costly downtime or product spoilage.

Therefore, considerations by food and beverage manufacturers over the selection of pumping solutions should be made intelligently.

Examples of Temperature and Pressure Ratings for Specific Applications

For example, dairy pumps have to endure temperatures above 80°C during pasteurization, while brewing pumps have to endure pressures above 5 bar.

All these specific application requirements would be useful for manufacturers in selecting the right kind of pumps which will make operations efficient and safe.

Pumping Liquids with Particles or Viscosity

Issues with Viscous and Particle-Containing Liquids

Thick and particle-laden liquids have some special problems when the process of pumping occurs.

Viscous liquids may cause clogging, while particles may cause abrasion to pump parts.

These in turn can lead to disruption in production processes due to increased maintenance cost and downtown.

Types of Submersible Pumps Suitable for Such Conditions

Certain types of submersible pumps are suitable for challenging liquids.

Progressive cavity pumps, for example, perform best in viscous liquids, while diaphragm pumps may work effectively in liquids that contain a high number of solids.

Performance efficiency when these challenges are present is very much related to the selection of proper pump type.

Optimal Performance Behavior in Challenging Applications

These techniques, however, can be used by operators in improving the performance of pumping such difficult fluids.

The viscosity of the liquid can be handled by manipulating the speed of the pump as heating elements can thin out the liquids.

Specialized impeller pumps for solids can also greatly enhance performance in those specific situations.

Ensuring Product Quality and Safety

Significance of Submersible Pumps in Quality Maintenance of the Product

This helps preserve food products’ quality and safety.

Being submerged, the pumps thereby allow liquid transfers without contamination or degradation that may enable the end product to reach the required taste and safety standards.

Product integrity is not a compromise that one can afford in the food and beverages industry because it has direct implications on consumer health.

Importance of Regular Maintenance and Monitoring

Maintenance and monitoring are essential in ensuring that submersible pumps work at an optimal level.

Routine inspections can easily detect some problems before they actually happen and cause failure.

This reduces all forms of downtime together with maintenance costs.

In fact, a proactive maintenance schedule provides a guarantee that not only do pumps work efficiently, but also they meet all the set health regulations.

Ensuring Safety and Quality Throughout the Pumping Process

Several strategies can be implemented by the companies to ensure safety and quality during the pumping process.

This would involve the creation of a strong maintenance schedule, implementation of real-time monitoring of performance through built-in systems, and conducting training for staff on the best way to operate the equipment.

These will collectively help in ensuring a quality and safe product.

Energy Efficiency and Sustainability

Overview of Energy Consumption in the Food and Beverage Industry

Food and beverage industries are among the highest energy consumers; the high consumption rate contributes to huge operation costs and is an environmental concern.

For that reason, addressing energy consumption remains paramount for companies to contribute to sustainability and reduce the carbon footprint.

Benefits of Energy-Efficient Submersible Pumps

Energy-efficient submersible pumps can offer huge, long-term cost savings.

By design, such pumps can operate efficiently on lesser energy input, reducing operation costs and also responding to the call of humanity for sustainability.

This can increase business profitability by minimizing environmental impacts through optimized energy use.

Sustainability of Pumps: Selection and Operation

The development in the field of environmentally friendly material usage for pumps and the implementation of energy-saving technologies have proved effective for sustainability.

Periodical assessment of pump performance also contributes to further economies in energy and thus makes operations more sustainable in the long run.

Innovations in Submersible Pump Technology

Recent Advances in Pump Design and Materials

Recent innovation in design and construction materials has significantly enhanced submersible pumps in both performance and service life.

Advanced polymers and corrosion-resistant alloys are newer materials that serve to improve reliability and efficiency.

Such development enables pumps to bear up against adverse working conditions without their performance being affected.

Impact of Technology on Efficiency and Performance

The working of submersible pumps has been revolutionized by some technological changes, such as smart monitoring systems and variable speed drives.

This allows the pump to effectively respond to process variable changes in real-time with increased efficiency and reduced energy consumption.

Thus, manufacturers can improve their performance at a minimum of operational costs.

Future Trends in Submersible Pump Technology for the Food Sector

In future perspectives, increased automation, further integration with IoT systems, and a strong focus on energy efficiency will probably mark the roadmap for the development of submersible pumps in food industries.

This will permit food manufacturers to further optimize their manufacturing processes and enhance product quality while minimizing environmental impacts.

Conclusion

Industrial submersible pumps play a great role in ensuring the aspect of efficiency, safety, and quality of the product within the food and beverage industry.

Their aptitude for operating on a wide variety of liquids and operation conditions makes them indispensable in modern processing operations.

This means investing in high-quality submersible pumps, maintaining them regularly, and following hygienic standards.

Quality investments mean high product quality and safety for customers.

By protecting the customer, companies will improve their overall operational efficiencies.

Therefore, industry stakeholders are encouraged to make full use of new developments within submersible pump technology to enhance productivity and sustainability in operations.