Selecting the right size for a submersible pump is crucial for ensuring optimal performance and efficiency.

Whether you are dealing with a residential or industrial application, understanding the factors involved in choosing the appropriate size can help you avoid common issues such as pump failure, inefficient operation, and excessive energy costs.

This article will guide you through the essential considerations when sizing a submersible pump.

What Factors Should You Consider When Sizing a Submersible Pump?

What is the flow rate needed?

Determining the required flow rate is essential as it dictates how much water you need to move within a specific timeframe.

Measure your intended application, such as irrigation, drainage, or wastewater management, to accurately define this parameter.

A typical household may require 10-30 gallons per minute (GPM), while larger industrial applications might need hundreds of gallons.

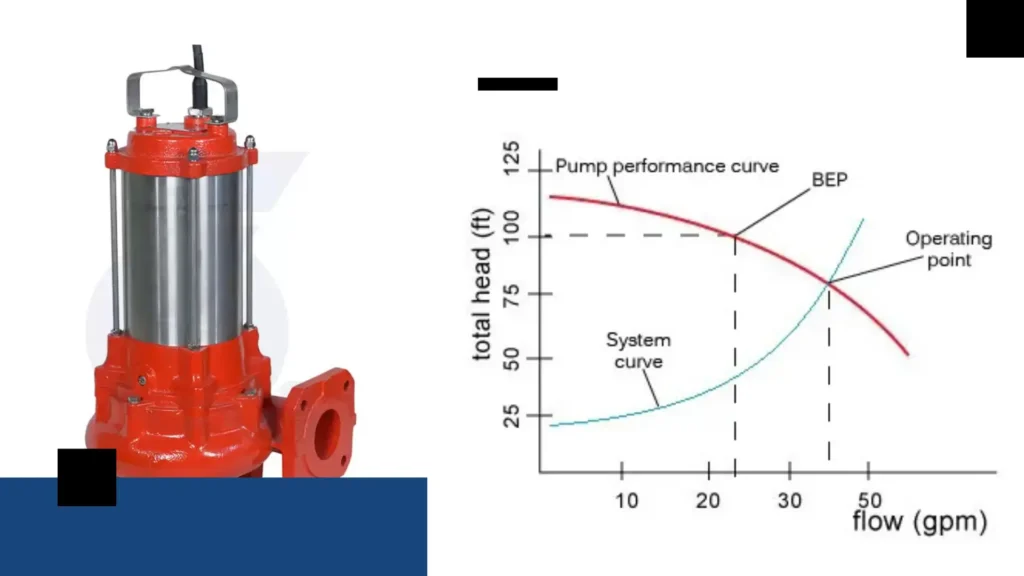

What is the total dynamic head (TDH)?

The total dynamic head represents the total height the pump must lift the water, factoring in elevation changes, friction losses in the piping, and any fittings or valves that may restrict flow.

Understanding TDH is critical as it influences the pump’s performance and efficiency.

What is the fluid’s nature and temperature?

The type of fluid being pumped as well as its temperature can significantly impact the pump’s performance.

For instance, corrosive fluids may necessitate specialized materials for the pump construction, while high-temperature fluids may not be compatible with standard pumps.

How often and for how long will the pump operate?

Understand the demand on your pump in terms of runtime. Continuous operation may require a different pump design compared to intermittent use.

If the pump runs frequently or for prolonged periods, you may need a larger or more robust model.

Also Read:

How to Choose the Right Submersible Pump Size Based on Flow and Head

How Do You Calculate the Flow Rate Requirements?

How to measure your flow needs?

Start by assessing the water demand for your application. If you’re using water for irrigation, calculate based on square footage; for a household, consider daily usage patterns.

This assessment should also take into account peak usage times during the day, ensuring that the calculated flow rate can meet high-demand scenarios effectively.

What tools can assist in flow measurement?

Utilize flow meters or calculate flow based on fixtures’ water usage. Many online calculators can help simplify this process, making it more intuitive for users.

These tools can provide precise measurements and help users visualize their water consumption needs over time, allowing for better planning and resource management.

Are there any standard flow rate guidelines?

Many applications follow standard flow requirements—as a simple rule, a typical residential garden could need around 1-2 GPM per 100 square feet, whereas more extensive agricultural needs or industrial uses can require extensive calculations.

Being aware of these guidelines helps ensure that the selected pump can handle the expected demands efficiently, avoiding over- or under-sizing that affects performance.

What to do if your requirements are more complex?

In certain cases where simplicity does not apply, consulting with a plumbing professional or pump specialist can yield tailored advice and accurate calculations based on your specific needs.

These experts can take into account unique variables such as landscape features, soil type, and existing plumbing systems to recommend the best options for your specific situation.

Why is Total Dynamic Head (TDH) Important?

What components contribute to TDH?

TDH includes static head (vertical distance from the surface of the water to the discharge point), friction loss through pipes, and any additional fittings or components.

Accurate calculation of these elements is vital for effective pump selection.

Neglecting any component may lead to selecting an inadequate pump that fails to deliver the required performance, resulting in potential operational issues.

How can you calculate friction loss?

Friction loss can be calculated using charts or equations that consider the pipe size, length, and material.

Online calculators can also provide quick estimates.

Knowing the amount of friction loss helps in accurately determining the total dynamic head, ensuring the selected pump can efficiently overcome these losses during operation.

What happens if TDH is underestimated?

Underestimating TDH risks selecting a pump that cannot handle the lift required, which can lead to premature failure, inefficient operation, and ultimately, increased costs.

This could also result in wasted energy and added wear on the pump, diminishing its lifespan and leading to unexpected maintenance expenses.

Can you adjust TDH post-pump installation?

In most cases, once installed, the pump selection is difficult to modify.

Therefore, performing thorough calculations beforehand is critical.

Failure to do so can result in costly reinstallation processes or replacements, which can disrupt operations and incur additional downtime related to your project.

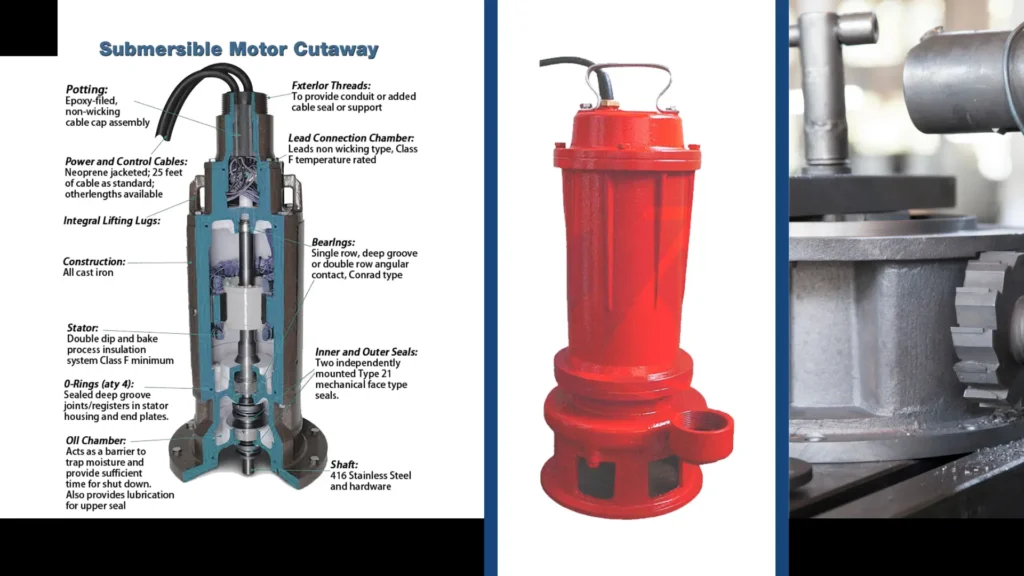

What Materials are Best for Your Submersible Pump?

How do materials affect functionality?

The material impacts durability, resistance to corrosive substances, and overall longevity.

Common materials include stainless steel, plastic, and iron, but your application will dictate the best choice.

Selecting inappropriate materials can lead to premature failure, increased maintenance needs, and ultimately, a more burdensome total cost of ownership.

What are the common material options?

Stainless Steel

Ideal for corrosive environments but may be heavier and more costly. This makes it a preferred choice in applications like wastewater treatment or industrial contexts where exposure to harsh chemicals is frequent.

Cast Iron

Durable and can handle high pressures, although it may rust over time. While cast iron is robust, careful consideration should be given to protective coatings or regular maintenance to enhance its lifespan when used in wet environments.

Thermoplastics

Lighter and corrosion-resistant, suitable for less demanding applications. Their versatility makes them suitable for residential uses, such as drainage or light irrigation systems, where added weight and strength of metals aren’t necessary.

What role does temperature play in material selection?

Certain materials are designed to withstand higher temperatures. Ensure the material chosen can comfortably operate within the temperatures expected in your application.

Choosing a material that cannot handle the operating temperatures risks altering the pump’s performance characteristics, potentially leading to failure or significant damage.

Are there certification standards to consider?

When selecting pump materials, always look for certifications that ensure compliance with industry standards—this ensures safety and reliability over time.

Certified materials are generally tested rigorously, providing added assurance that the pump will perform adequately under expected conditions and adhere to local regulations.

And More:

- Choosing the Right Submersible Pump for Waterworks

- How to Choose Environmentally Friendly Submersible Pumps

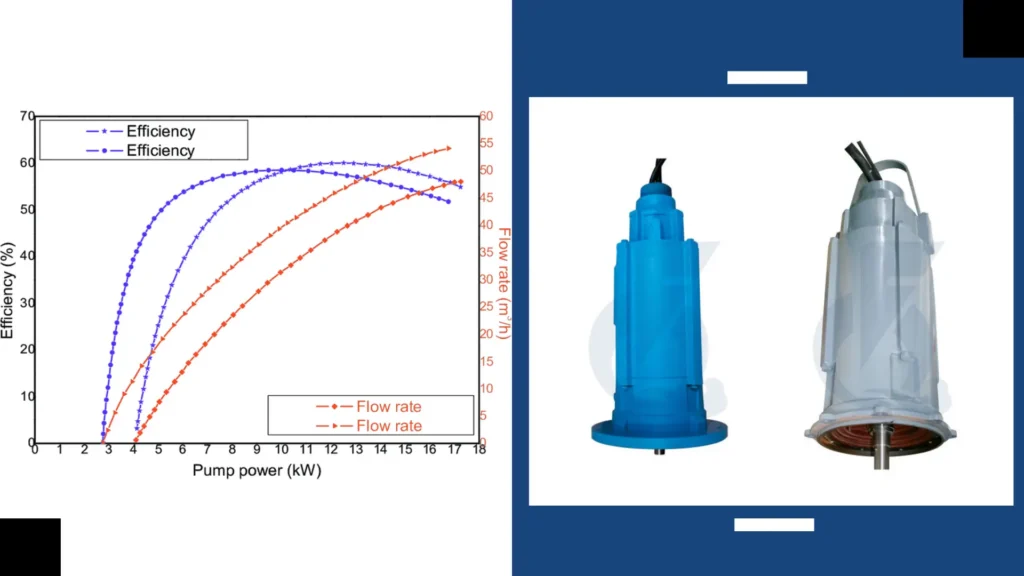

How Do You Determine Pump Efficiency Ratings?

What does pump efficiency signify?

Pump efficiency refers to how well a pump converts electrical energy into fluid movement.

Higher efficiency means lower energy costs and longer lifespan.

This effectiveness is critical in understanding how much operational cost can be offset by choosing the right pump, making it a vital factor in the decision-making process.

Why is it important?

Choosing an efficient pump not only saves money on operational costs but also reduces wear and tear.

This is especially important for pumps that will run frequently.

In frequent usage situations, the cumulative savings from a more efficient pump can be substantial over time, leading to significant overall operational profitability.

How can you find efficiency ratings?

Check the performance curves provided by manufacturers, which typically show efficiency across different operating points.

Performance curves allow users to visualize how the pump will behave under various flow and pressure conditions, empowering more informed choices based on their specific needs.

What happens if you choose an inefficient pump?

Using an inefficient pump can lead to unforeseen expenses due to higher energy consumption and increased wear, necessitating more frequent maintenance or replacement.

This inefficiency can also create ripple effects, potentially leading to operational downtime and other indirect costs that affect overall project budgets and timelines.

How Can You Simplify the Selection Process?

Are there tools available for easier selection?

Many manufacturers offer online calculators or software to aid in selecting the right pump size based on user-inputted parameters such as flow rate and TDH.

These tools can provide instantaneous feedback and recommendations, allowing users to input their specific requirements without needing in-depth technical knowledge.

Should you consider consulting a professional?

If the process feels overwhelming, don’t hesitate to consult with a pump supplier or engineer.

Their expertise can help navigate the complexities and ensure a suitable choice.

Consulting professionals not only saves time but also increases the likelihood of selecting the most efficient and appropriate pump for your application, avoiding costly mistakes.

but also increases the likelihood of selecting the most efficient and appropriate pump for your application, avoiding costly mistakes.

What resources are available for learning more?

Numerous industry websites, forums, and educational workshops provide valuable insights on pump technology and sizing practices.

Leveraging these resources can greatly enhance your understanding.

Additionally, participating in webinars or attending industry trade shows can connect you with experts and peers, facilitating valuable exchanges of information and experience.

Are there common mistakes to avoid?

Avoid common pitfalls such as neglecting to consider fully dynamic head and flow requirements.

Additionally, ensure you are not selecting based solely on price without considering the right specifications for your needs.

By being cautious and informed during the selection process, you can avoid making decisions that may lead to inadequate performance or increased long-term operational costs.

Conclusion

Choosing the appropriate size for a submersible pump is a multifaceted process requiring careful consideration of various factors, including flow rate, total dynamic head, fluid characteristics, and efficiency ratings.

By understanding these elements and utilizing available resources, you can make an informed decision that meets your specific needs while optimizing performance and cost-efficiency.

Don’t rush the decision; the right pump can make all the difference in the long run.