Water management spans an important component of various industries, which range from agriculture to municipal services.

Efficient water management ensures a sustainable supply, cuts down on waste, and improves productivity.

Submersible pumps will be a significant factor in this process.

But how do they actually create or help improve the water management system?

The article discusses the features, advantages, and industrial impacts of submersible pumps and provides enough insight into their significance.

Learn More:

- What is a Submersible Pump and How Does it Work?

- Advantages of Using Submersible Pumps in Agriculture

- How to Test a Submersible Pump?

What Are Submersible Pumps?

Following are three identifying features of the submersible pumps:

Compact Design

The design of submersible pumps is such that their footprint is small, making them very suitable for installations in tight or just difficult-to-reach areas.

In addition, it allows easy incorporation into existing systems without major modification.

High Efficiency

These pumps are designed for efficiency and are able to move large volumes with minimal energy consumption.

Minimized operating costs are not only a result of this, but such pumps also offer a smaller carbon footprint and hence are also environment-friendly.

Versatile Applications

In fact, submersible pumps can be applied within different environments: residential areas, agricultural fields, or even industrial sites.

Adaptability to environment and different requirements is definitely one of the strong points that make submersible pumps applicable for numerous tasks related to water management.saved

Product Remmend:

Benefits of Using Submersible Pumps

Higher Efficiency

One of the major benefits that come with the submersible pumps is the ability to work efficiently.

In their design, they minimize energy usage while maximizing output.

The increased efficiency eventually translates into higher cost savings after some time, given that lower energy consumption means less utility bills.

Sometimes, since these water pumps always provide water directly from the source, they can work faster than other conventional pumps and provide water in the shortest time possible.

Reliable Operation

The construction of submersible pumps is to resist such hard conditions as deep wells or flooded areas.

Their rigid construction allows them to operate without fail even in harsh conditions.

This once again reduces maintenance and, consequently, reduces their total downtime-a factor very important in industries relying on round-the-clock water supply.

Since they do not break down easily, or get repaired often, it saves businesses from having to worry about water management problems and focus on their core business.

Quality of Water Improved

The submersible pumps save water from stagnation by keeping it in movement, hence fresh and clean.

This is very important in agriculture, as the quality of water determines the health and yield of crops.

High water quality is quite essential in municipal water systems to protect public health, and these applications make submersible pumps valuable in helping to ensure safe drinking water.

Flexibility and Adaptability

These pumps are immensely versatile; from dewatering construction sites to irrigating crops, they can be set up in everything.

Their versatility extends the usages to a wide array of water managing strategies.

For example, during heavy rainfall, submersible pumps can rapidly get rid of water from basements or low-lying areas and prevent flooding. In agricultural applications, they may be fitted with specific irrigation needs to ensure that water is supplied to the crops at the optimal level.

Key Considerations When Choosing Submersible Pumps

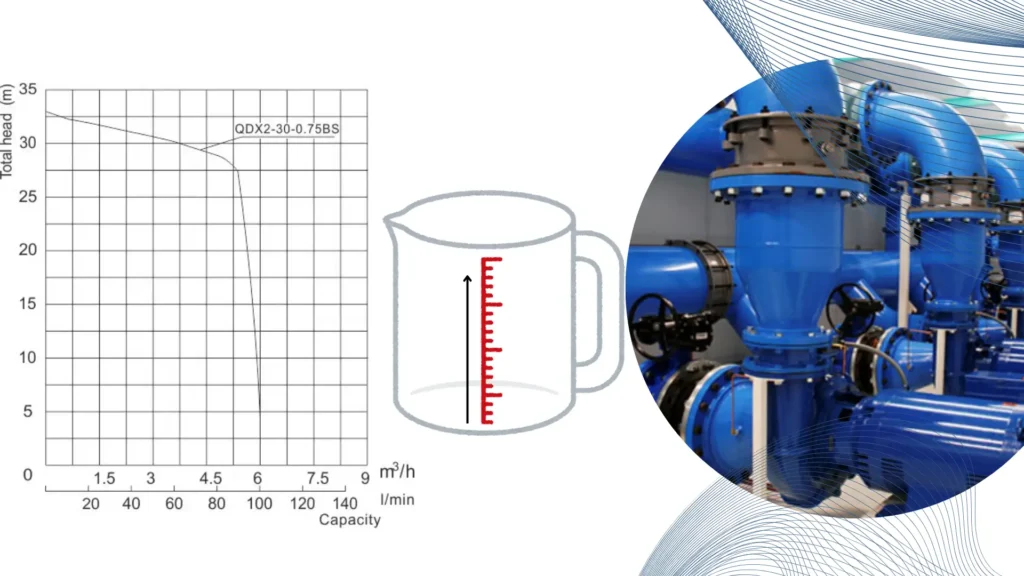

Size and Capacity of the Pump

One of the central decisions to be made, if one desires to achieve optimized performances, is the selection of appropriate size and capacity of a submersible pump.

It should be able to handle the volume of water that may be required for any given application.

One would, therefore, consider the depth of the source of water flow against one’s desired flow rate to arrive at the right specifications for the pump.

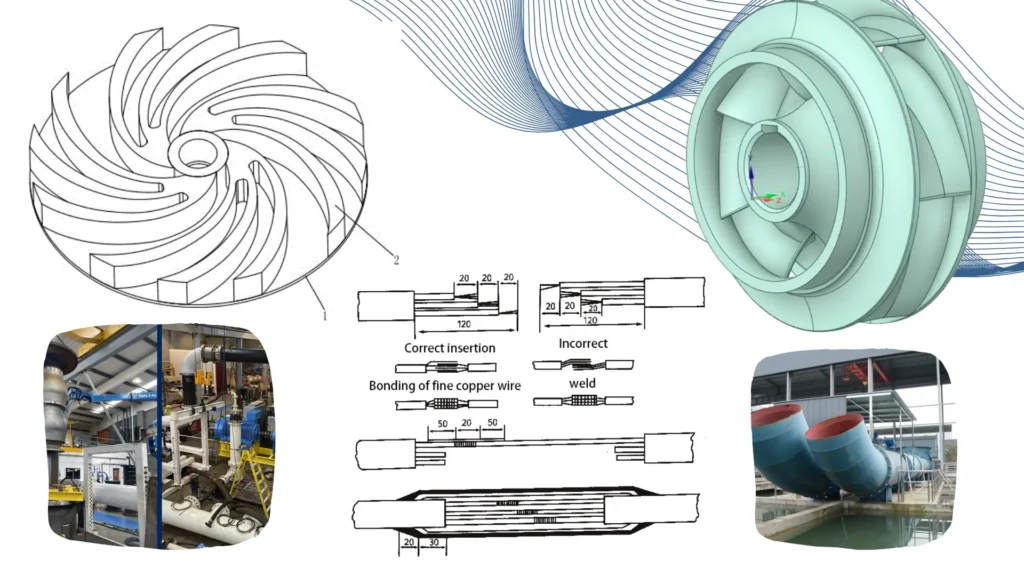

Material and Durability

Materials of construction for submersible pumps greatly influence their performance and operating life.

The manufacturing materials used in the pumps should at least be corrosion-resistant, using stainless steel or high-grade plastics, especially in challenging environments that require durability.

These kinds of pumps ensure low maintenance and replacement costs due to good resistance against the conditions of operation involved in an application.

Energy Efficiency

When choosing a submersible pump, consideration should be made for those that are energy-efficient.

It is wise to opt for those with high-efficiency motors and features that reduce energy consumption.

Although these noise-makers are relatively costly to purchase, after some time substantial amounts of money are saved on utility bills; hence, they become relatively cheap in the long run.

Maintenance Requirements

Knowing a submersible pump’s maintenance needs will greatly benefit its lifespan and performance.

Certain pumps need periodic checks, and others are constructed to require little maintenance.

We choose pumps that match your operational capabilities to minimize any sudden stops and repairs.

Innovations in Submersible Pump Technology

Advancements in technologies for submersible pumps are not standing still.

They mean improvement in performance and further effectiveness of submersible pumps.

Some helpful developments in submersible pumps have been underlined below.

Smart Pump Technology

The latest phase in the evolution of the submersible pump saw the inculcation of smart technologies.

Many such submersible pumps in their latest avatar possess the smart capability for real-time monitoring and control.

The users are able to monitor performance parameters, early fault detection, and optimization of operation schedules for effectiveness and cost efficiency.

Variable Frequency Drives

Submersible pumps with VFDs can make necessary adjustments according to demand.

The variable frequency drive alters the pump speed in a way that minimizes energy consumption and reduces mechanical stress on the pump to extend its life.

This technology is most useful for applications where water demand varies.

Advanced Materials

Material science innovations have resulted in the development of more durable and resistant components.

Advanced materials enhance the durability and reliability of submersible pumps, especially for those applications involving hostile environments where conventional materials may fail.

Eco-Friendly Designs

This becomes a greater motivation for manufacturers in order to design their products in an ecologically friendly manner.

For pumps, this translates into pumps designed for using a minimum amount of energy, and parts designed to be recyclable in order to limit environmental impact once the pump is actually operational.

Such designs help not only the planet but are also extremely appealing to ecologically sensitive consumers.

How Submersible Pumps Impact Various Industries

Agriculture

The contribution of these submersible pumps in agriculture, for better irrigation mechanisms, is immense.

This provides the required amount of water to the crops at the right time, which in turn is very significant concerning the production of yield.

Such pumps will help farmers in automating irrigation techniques by saving labor and hence optimizing the usage of available water resources.

This will not only raise productivity but also conserve precious water to help in sustainable farming.

Municipal Services

Municipalities rely on submersible pumps in handling wastewater and stormwater drainage.

These pumps remove excess water from the street and low-lying areas with rapidity, preventing the occurrence of flooding in heavy rains.

These are also crucially utilized in sewage systems, where going to treatment is effectively the movement of wastewater.

Good drainage and sewage management contributes to guarding public health and improving the quality of life in citizens.

Industrial Applications

Submersible pumps are essential in many industrial applications because the process requires uninterruptible water supply.

Their applications include cooling systems, manufacturing processes, and other vital uses related to water.

Their high efficiency enables them to minimize the cost of operation; as such, this enables resources to be allocated efficiently within the industry.

In addition, their unhindered operation ensures smooth production processes, an outcome that minimizes the chances of costly interruptions.

Conclusion

The new transformative technology in water management systems is submersible pumps.

Submersible pumps, owing to their efficiency, reliability, and adaptability, have turned indispensable in a number of industries.

Investment in submersible pumps would help businesses and municipalities advance with the best water management strategies for prudent management of resources and sustainability long-term.

This could prove to be the factor that changes the game in your agricultural, municipal service, or industrial water management needs.

This will not only improve productivity by embracing the technology but also contribute to a greener future.