Testing of the submersible pumps is quite critical for any homeowner, contractor, or anybody having a submersible pump for supplying or draining water.

Knowing how to perform testing on such a pump may grant you significant insight in making your best decisions and optimum performances.

This guide simplifies the test processes, hence making the procedures accessible and easy to follow.

Understanding the Basics of Submersible Pumps

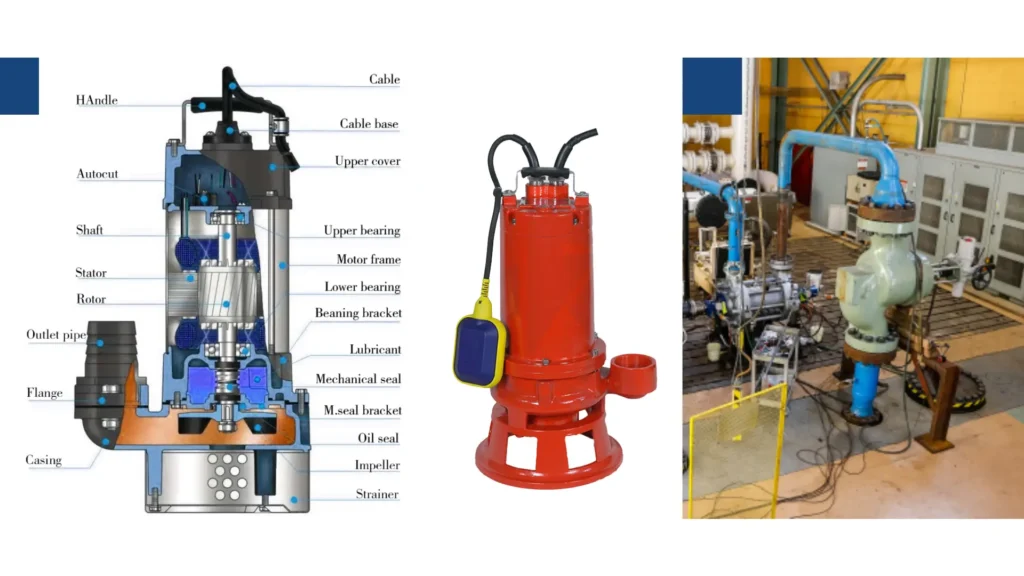

What Is a Submersible Pump?

It does this function by pushing the fluid upwards with the use of a series of impellers.

These are, however, generally useful in residential wells, sewage, and irrigation systems.

In all these applications, they are quite effective and very reliable to transfer water from one place to another.

Learn more:What is a Submersible Pump and How Does it Work?

Why Testing is Important

You will be able to identify small problems early enough that your pump will continue to work well.

Early identification of problems before they worsen will help you avoid costly repair works that will prolong the life of the pump.

Common Applications

Residential Water Supply

These pumps are submerged in water in the source and are, therefore, able to suck water from where no other pumps can manage.

They push the water to the surface for an uninterrupted, reliable supply for drinking, cooking, and other uses in the household.

Having this continuous water supply allows homeowners to have the convenience of modern plumbing without interruptions.

Besides, many submersible pumps are designed in a way that they can save energy; this may mean lower utility bills over time.

Wastewater Management

Submersible pumps play a very important role in wastewater management in terms of safe and efficient ways of handling sewage and wastewater.

Thus, they operate submerged in sewage pits or basins in order to shift waste, sans any possible overflow or contamination, to treatment facilities or septic systems.

Their solid construction also allows them to process solid wastes and debris; hence, they are suitable for use in both residential and commercial settings.

Due to the fact that submersible pumps handle wastewater well, they prevent environmental hazards that affect the public health by ensuring sewage is processed and that water sources around the community are not contaminated.

Irrigation Systems

Submersible pumps serve as a helpful implement in irrigation systems, especially in agriculture and landscaping.

These pumps draw water from underground sources, such as wells or reservoirs, to create a regular supply of water to crops and gardens.

Such submersible pumps are quite important for farmers and landscapers as they assure the delivery of water with efficiency directly to the root zone, hence promoting the growth of plants for better yields.

Automation of irrigation by the use of submersible pumps allows the farmer to have better water management to minimize waste and at the same time give the plants just the right amount of moisture.

This will not only improve productivity but also aid in employing good water use practices within sustainable agriculture.

Learn more:

- Types and Applications of Submersible Pumps in Agriculture

- What is a Submersible Pump Used For?

- Benefits of Submersible Pumps in Farming

- 10 Features to Look for in Submersible Pumps

Preparing for the Test

Safety First

Safety first before testing. Always switch off the power supply to the pump to avoid electrical hazards.

Clear the area around the pump of water and any obstacles for safe access.

Tools Required

Multimeter

It is one of the useful tools that one should have during the testing of a submersible pump.

The device will measure voltage, current, and resistance. Therefore, it is a crucial device that one can use to identify most electrical faults.

You can use a multimeter to check if the voltage at the head of a submerged pump is proper from the power supply when you test a submerged pump.

This is very critical, as too little voltage will underfeed the pump, making it perform very badly or not at all.

A multimeter will also allow you to test the continuity of wiring for any breaks or shorts that may exist, impeding operation.

The regular use of the multimeter will keep the electrical health of your pump in order and avoid unexpected breakdowns.

Flow Meter

One of the key instruments of measurement for the output of a submersible pump is the flow meter.

This device will give the amount of water being pumped within a specific period, hence enabling you to assess the efficiency of the pump.

Once the flow rate is known, you can have an idea if the pump operates within capacity or not.

A flow rate smaller than expected can testify to blockages, wear, and damage to the components of the pumps.

In regular applications, a flow meter helps you to keep the performance optimal and makes sure that your water supply does not get interrupted in household or agricultural applications.

Pressure Gauge

Pressure is an important tool one could use in assessing the level of pressure produced by such a submersible pump.

By attaching a pressure gauge to the discharge pipe, one will be able to measure the pressure of the water being pumped.

Information on the pressure becomes vital, as it offers guidelines on whether the pump is operating within the specifications set by the manufacturer.

Abnormal pressure readings can indicate potential issues that may block in the piping or wear of the impellers in the pump.

The routine checks with a pressure gauge not only ensure your pump runs efficiently but also prevents problems that may lead to costly repairs or system failures.

Checking the pressure level is among the proactive ways to ensure that your submersible pump performs and remains in good condition.

Product Recommend:

Conducting the Test

Visual Check

Leaks

First and foremost, a good way to ensure your submersible pump works well is with a keen and detailed visual check.

Check the general area around the pump and related piping for leaks of any sort.

Pooling or droplets of water may come from seal or connection failures. Small leaks often lead to considerable amounts of lost water over time, which leads to larger utility bills and even further damage in areas around them.

Leakages, if these are found, should be tightened up straight away by tightening fittings or replacing seals to avoid further problems.

Electrical Connections

The electrical connections also have to be checked for being properly secure and in a healthy state.

Frayed wires should be seen for because of the danger of insulation wearing through, which could lead to the possibility of short circuits and, thus, to pump failure and electrical hazards.

Corrosion on the terminals or connectors can also limit electrical flow and impede the performance of the pump.

In case you find any corrosion, then either clean the connections or replace such corroded parts.

Careful examination of electrical connections is necessary for continued reliability and efficiency in your submersible pump.

Electrical Testing

Voltage

Once the above visual checks have been made, electrical testing can be carried out.

Using a multimeter, check whether the proper voltage is applied to the pump according to the manufacturer’s requirements.

It is very important to do this step, as low voltage sometimes prevents the proper working or totally stops the pump from working.

The voltage measured at the power supply connection must be appropriate according to the requirements.

If that voltage is less than what it ought to have been, then trace the probable causes of such malfunctioning which may range from a problem with the power supply to faulty wiring that needs replacement.

Continuity

Besides voltage testing, there is also continuity testing of the wiring. It means using the multimeter for testing breaks or faults in the electrical circuits.

Continuity testing will show if there is a problem that you cannot see, such as an internal break in the wire. If continuity is not available, then operation of the pump could be impaired in a way that would lead to operational failure.

Any wiring issues should be quickly determined and remedied to maintain the operational effectiveness and life of your pump.

Performance Testing

Flow Rate Measurement

Now that the electrical components have been checked, the submersible pump is ready for performance testing.

First, the flow rate measurement might be conducted on a pump by use of a flow meter.

This tool measures the amount of water that passes through a pump within a specified time limit.

This helps in understanding its effectiveness. A flow rate that meets or is above the manufacturer’s specification means it’s functioning as it should.

On the other hand, a flow rate that is smaller may indicate some possible issues, such as blockages, wear, and other forms of damage to the pump parts that require immediate attention.

Pressure Check

Attach a pressure gauge on the discharge pipe to conduct a pressure check.

It will be able to record the levels of pressure the pump will be able to generate, which must ideally fall within the recommended parameters as instructed by the manufacturer.

Pressure monitoring is important because any abnormal reading may indicate an existing problem that can involve blockage in the discharge line or some mechanical failure within the pump.

Periodic testing of pressure will enable one to maintain good performance and early fault detection to offer long life to the submersible pump with service reliably.

Noise and Vibration Analysis

While the pump is running, listen carefully for any abnormal sounds.

More noise or vibration than expected could signal mechanical faults, such as misalignment or wear, which may be in need of further inquiry.

Conclusion

It is not just a technical job that testing of the submersible pump requires but one positive step toward guaranteed water supply and drainage.

By observing this easy procedure, one can sustain the efficiency of their pumps and avoid very expensive repairs, besides being secure in the knowledge that the system operates properly.

Your submersible pump will continue serving you with regular maintenance and testing to continue the supply of water for all purposes in a continuous and reliable manner.