Energy efficiency has graduated from the world of jargon to be a necessity in today’s economic scenario.

Price levels of energy and environmental modernism constrictions have started pressurizing the commercial organizations to govern the way they consume as well as optimize the consumption of energy.

Maintenance jobs on high-performance pumps also have the potential to provide energy savings in the equipment which also result in other savings in utility costs.

Pumps of high performance are those engineered for better efficiency as compared to normal pumps and significantly contribute to energy loss reduction during operation by virtue of having the most advanced technologies, innovation in design, and better materials.

These pumps are designed to maximize energy transfers and can cater to most applications by improving performance.

Identifying and understanding the characteristics and benefits of high-performance pumps can help in making the best and most informed decision when choosing products.

And More:

- Maximizing Efficiency with Energy-Efficient Submersible Pumps for Waterworks Projects

- 7 Key Benefits of Submersible Pumps in Water Management

How Pump Design Affects Efficiency

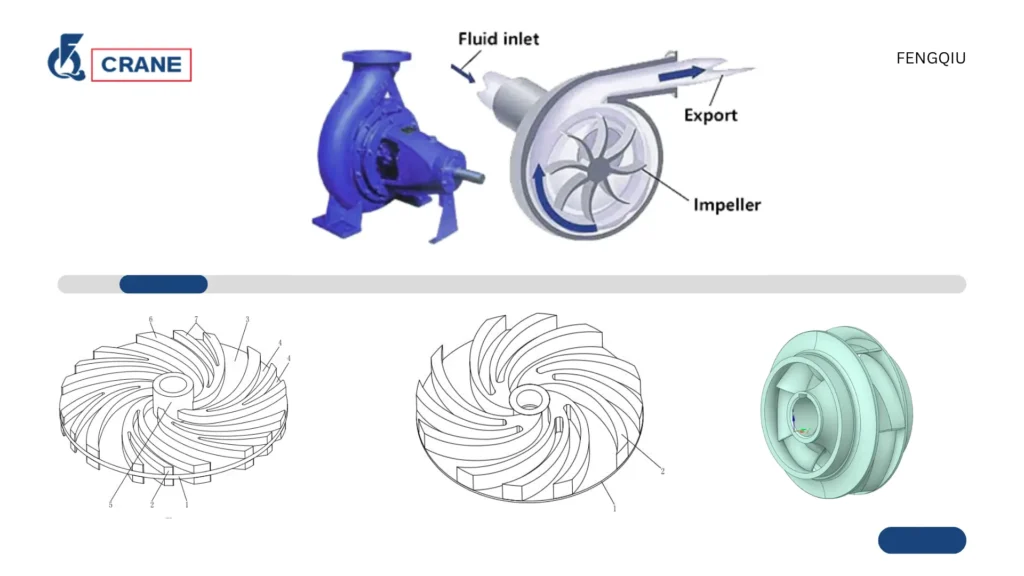

Factors Affecting Impeller Design

The impeller literally shuts other factors off in order to provide ample power to the pump in order to give a chance for the pump to work efficiently and perform its task.

Therefore, the precision equipment adopted in the packaging, specifically the impeller, has undergone some improvements.

The high-performance pumps will then carry new impeller designs that, in short, facilitate good liquid flow and reduce disturbance, thus giving the opportunity to work smoother and perform more efficient energy transfer with minimal loss of energy during the pumping process.

A good impeller designed very well ultimately increases the overall efficiency of the pump, allowing it to be properly harnessed for a greater output.

Motor and Drive System

The motor and drive system of a pump have a very significant role in the performance of the pump, not just for its entire life but in its drafting also.

High-efficiency pumps normally feature high energy-efficient motors with minimal power consumption and maximum output as well.

Many state-of-the-art pumping units are designed with variable frequency drive (VFD) mechanisms that are capable of adjusting the speed of the motor according to the demands of certain fluids.

This feature ensures not only energy conservation but also a more accurate operational control of pumps, boosting better results and lower energy costs.

System Compatibility in a Pump

It is also important to note that the level of pump efficiency will be influenced by the compatibility it has with the whole pumping system.

Smaller-sizing the pump for the given application and proper installation of the pump in its optimal operating range can realize huge energy savings.

Sometimes, however, improper-sized systems cause the pump to work harder than necessary, thus increasing energy consumption and wear.

Thus, consulting experts during selection can help ensure that the pump will smoothly integrate into the system already at the same time upping efficiency and performance.

Benefits of High-Efficiency Pumps

Cost Saving

One of the most immediate and real benefits of high-performance pumping is the real prospect of a significant saving in money.

Less absorbed energy for these pumps, lower electricity costs, some cost savings are achieved.

Eventually, these savings outweigh the purchase price of these items- then businesses can definitely spend more of these savings for their operational improvement.

And this can lead directly to an increase in the company’s total productivity.

Environment Impact

Energy saved from pump operations has several environmental merits, as a reduction in the carbon footprint is evident since its allocation in the system results in less energy being used that normally has a larger CO2 output when working.

Thus, the waste emitted from these work processes will be neutralized, which seems to convince customers buying it and the regulatory bodies as well.

That is why firms will more likely take this into consideration as it builds company image.

Extended Equipment Life

High-performance pumps are commonly created from better materials and with superior design to bring all the break and wear issues to a minimum.

Because of this durability of pumps, equipment life improves, breaks or maintenance go down the frequency and, most importantly, costs of maintenance are reduced.

Business benefits highly from these pumps, as they have a higher reliability and efficiency by way of high quality and less waste of their operations.

Identifying Energy-Saving Opportunities

Energy Auditing Existing Systems

Doing an energy audit of existing pumping systems is the first, most important step in discovering their potential opportunities for energy saving.

This audit, forwarded, can identify obvious chances such as oversized pumps, outmoded technologies and improperly sized piping, which would consume more energy.

Such issues are a key reason why the audit performance is done so that an organization can determine where the efficiencies are, and can therefore take focused measures to enhance the performance of its facilities while saving energy.

New High-Efficiency Pumps

High-efficiency valves are a great solution and can result in very significant cost savings for a business.

At first, the investment might be heavier than standard pumps, but it always pays for itself in the long run.

Such careful attention to the ROI is necessary to meet the necessary business decisions with a sound financial backing that maximizes functionality.

Smart Controls

Systematically integrating smart controls into pump systems would enable real-time demand response operation modification and enhancement as it is necessary to function.

The effect is further boosted by having these systems function in such a way that the pump has to be operated only when it is necessary, thereby ensuring drastically reduced energy wastage.

Therefore, with such technologies becoming real, businesses can make use of innovative energy management techniques that will keep them competitive in an energizing market.

Performance Monitoring and Optimization

The Importance of Monitoring Operations

Monitoring the performance of pumps is vital for them to maintain maximum effectiveness.

Vital to this process is predisposing explicit abatement by observing strategic performance indicators (KPIs).

This way, organizations may be alerted to any performance decreases that can permit corrective actions to be promptly taken before significant energy loss is incurred.

In addition, they may confirm the efficacy of energy-saving measures and confirm that pumps are functioning at peak efficiency.

Predictive Maintenance

The implementation of predictive maintenance strategies serves to prevent inefficiencies due to equipment wear or failure, as they enable devices to predict and thus prevent potential problems by utilizing data analytics and sensor marks beforehand.

It also increases the life of the pumps leading to further electricity savings through less maintenance costs.

Continuous Improvements

Continuous improvements in energy management will provide a culture of sustainable energy performance by recapping and improving pump performance, enabling organizations to cope with changing conditions and technologies for continuous energy savings.

Continuous commitment to improvement encourages innovation and keeps organizations agile in fierce competition.

Choosing the Right High-Performance Pump

Determining What are Needed by the Application

To pick a really high-performance pump, it necessitates someone to understand what the specific application requires.

Elements like the type of fluid, flow rate, pressure requirements, and operational conditions, all these count in selection.

Such components should be clearer to make sure whoever chooses the pump, serves the operation’s requirement in the best way in order to achieve maximum performance.

Communication with Specialist

Involvement with pump experts can open good avenues in the way of selecting appropriate machinery.

Specialists normally have the freedom of viewing the equipment on their basis of efficiency, reliability, and overall performance, while ensuring that the firm evaluates critical factors making businesses better fitted to the goals.

Because of their contributions to the understanding of pump selections, real effects will be felt in the heights achieved through good attainments.

Checking the Credential of Manufacturers

A sought-after product from a company that has constantly proven its quality and reliability in manufacturing high-performance equipment may have a significant impact on the optimal performance of the system.

Companies must be able to study the various manufacturers and product offerings to ascertain that their investment converges with what are committed by the vendors.

The reputation of a good manufacturer might often imply better performance as well as support for the customer.

Conclusion

In totality, high-efficiency capability in the range of high-performance pumps offers vast potential for energy conservation.

This filtrated product yields a number of benefits like realized cost savings, reduced impact on the environment, and longer life of equipment serviced.

Consequently, business people can make up their minds by scrutinizing qualities of the design and operational strategies that build on efficiency to add success to their initiatives.

Justification of the capital expense behind these pumps stands as a proactive step in enhancing as well as sustaining energy efficiency among a good number of assets and liabilities.

High-ranking energy-saving technology in the list implies complementing planning, which is used for building up business and environmental performance in the process of benefiting business.

Energy costs are rising while sustainability as well as green consciousness take slow blossom.

Businesses need to evaluate their pumping systems now because high-efficiency solutions create value and are considered strategic operation enhancement methods that provide very significant savings in energy with overall operations efficiency enhancement.

The future is around the corner. Start this day to lay that cornerstone for a much more efficient and much more responsible future.