It is hard to overestimate the role of industrial submersible pumps in many industries, such as wastewater treatment, underground works, agriculture and other fields of economy.

Submersible pumps are those instruments employed underwater and with the water circulating around, they have an enclosed motor that is not susceptible to the ingress of water.

This is essential for plants that treat wastewater, for example, or for the extraction of minerals or for the storage of water as in cases of irrigation, and this is where submersible pumps could be of great use.

These devices facilitate the use of water resources as the pumps are efficient and can be relied on without necessarily refurbishing or maintaining other parts of the plant.

Learn More:

- The Ultimate Guide to Industrial Submersible Pumps

- Key Performance Parameters of Industrial Submersible Pumps

- Overview of Submersible Pumps for Irrigation and Waterworks

Design Features of Submersible Pumps

Construction Materials

Submersible pumps are made up of a range of materials with predominance of stainless steel and inclusion of thermoplastics.

The choice of stainless steel is because of its high tolerance to rust and its strength making suitable for rugged conditions or environments where abrasive or corrosive liquids are used.

At the opposite spectrum however are the thermoplastics which provide an lightweight alternative free of wearing and capable of being so designed that very complex shapes are ensured to give the pump a satisfactory hydraulic performance.

Types of Motors

The design of the motors of these pumps are all water proof because they swim in water which comes with its set of demands.

Often advanced coolers are fitted in these motors to ensure that they continue to work even while they are water still.

This cooling is an important aspect concerning the motor since the prevention of overheating avoids motor malfunctions.

Moreover, in other cases the motors are enclosed with the whole pump system to seal the motor away from water hence ensuring that the pump can always be used and that it never fails.

Blades Arrangement

Submersible pumps have its kind of impellers each with its own design such as open impellers closed impellers and vortex impellers.

Open Impellers are designed to run on fluids while removing some particulate in them and are usually employed in waste water handling systems.

Conversely, Closed Impellers could have the best performance however, they are used for applications where the fluid is clean.

To cater to different requirements based upon the fluid and operational conditions, different kinds of impeller configurations can be adopted in pumps.

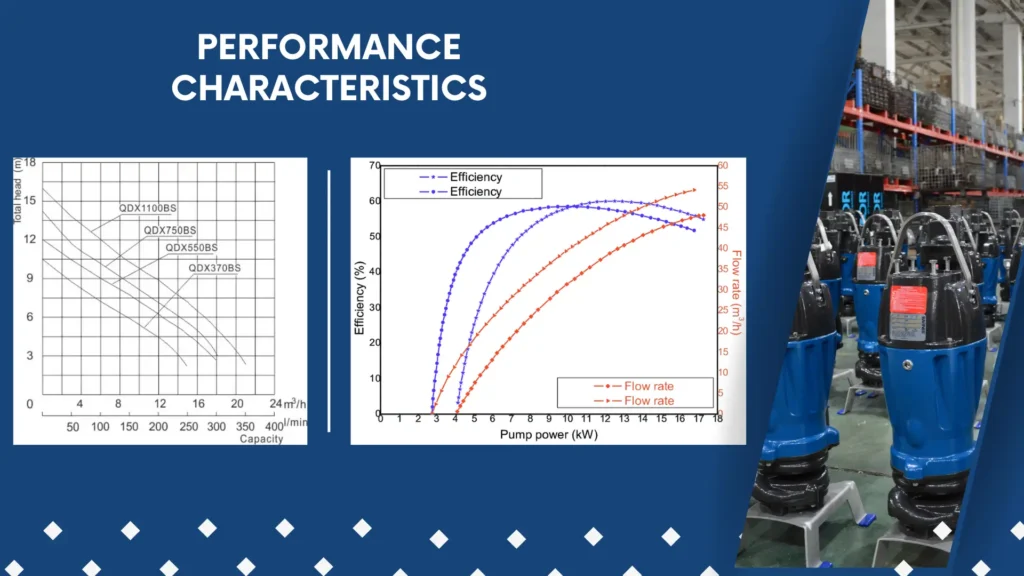

Performance Characteristics

Pumping Flow Rate

Flow rate is one of the main variables that come into play in submersible pumps and determines the amount of liquid that can be raised by the pump in a certain time, usually in gallons per minute or liters per second.

As flow rate increases, more fluid can be moved within a short time facilitating rate of flow in terms of production.

Understanding the notion of flow rate is helpful to the end users in that it enables them to determine if a particular pump will be able to aid in doing some of the work that involves fluid.

Viscosity

Total Dynamic Head (TDH) is a critical performance characteristic that refers to the maximum height a submersible pump can lift water.

TDH is essential for selecting the appropriate pump for specific tasks, as it determines whether a pump can deliver water to the required elevation or distance.

Users must calculate the TDH basing on the particular requirements of their systems so that the pump performs well.

Efficiency Metrics

Identify methods for evaluating how much power a submersible pump is able to generate hydraulic power from the input of electrical power.

These measures most often pertain to the efficiency of the pump as well as the efficiency of the entire system and it can have a huge effect on the costs of running an operation.

If the pump is rated as more efficient, less energy will be consumed while achieving the same amount of work, therefore cutting down the amount paid on electricity bill and helping in reducing the carbon footprint.

Installation Best Practices

Corrective Maintenance Procedures

It is necessary to observe the necessary measures as seal checks will help avoid the invasion of water into the motor thus the possibility of motor failure.

Filters must also be cleaned to avoid blocking which can lead to low flow rates and increased power consumption.

General maintenance enables the operator to catch potential issues and fix them in the early stages, thus minimizing the downtime of the pump and increasing its longevity yet again.

Common Troubleshooting Techniques

Resolution of multiple problems that can be met by submersible pumps call for the knowledge-not only of the functionality of the pump and its components, but of possible causes of malfunction.

For example, if one is not getting the required flow, impeller might be clogged or the discharge line might be chocked.

In circumstances such as this one, it can be pragmatic to attend to such issues such as cleaning or replacing of components to which the damage has been caused thus preventing worsening of the situation.

Environmental Impact and Sustainability

Electric Power Saving

The design of contemporary submersible pump assemblies provides enhanced energy efficiency.

In many cases advanced motor and variable frequency technology is used helping motor pumps to adopt demand based energy consumption strategy.

By using efficient pumps, it is possible to achieve the objectives for sustainability while at the same time gaining cost savings through cutting back on electricity consumption.

Noise Levels

Many components in most pumps discharge noise when used such that in places where people perform their daily function or in operations that demand silence like customer service centers, the use of submersible pumps becomes a nightmare of noise.

Acoustic aspects ensure noise free conditions of use of submersible pumps, that their day to day use conforms to standards most probably within townships where noise should be controlled as the highest.

Sewage Treatment

Submersible pumps are widely employed in the collection and transportation of sewage from industrial and urban centers for treatment.

In addition to facilitating the processing of waste and preventing any health hazards, the management of waste water using these pumps also becomes a system of environmental protection.

Submersible pumps can be included in tools used in handling wastewater where they help the municipal and industrial communities go about their daily business and at the same time adhere to the environmental policy of the country.

Selecting the Right Submersible Pump

Evaluating Usage Requirements

One of the key procedures when deciding to buy a submersible pump is to consider the many factors that bear on the performance in the use of a given submersible pump.

The nature of the fluid is the first thing to be kept in mind for the reason that a pump that is designed for clean water for example, may not be apt for condone in the case of wastewater treatment.

This will save the consultant from the inconvenience of procuring a pump which might need to be ripped off due to lack of the necessary conditions and executing the process all over again.

Professional Advice

Conversations of the kind with a pump selection professional tend to change the outcome of any situation by either providing the user with invaluable experience or recommending them on safe engineering practices.

Pump experts will help in decoding submersible pump specifications and features in a way that these enable the operation requirement of the pump in question.

Moreover, they are specific enough to help the user of the pump to predict problems in advance and suggest mitigation measures fitting the situation and standard.

Allocating Resources for Future Benefit

Using a lesser efficient pump may also be more expensive at the present but more cost effective in the long-run.

Moreover, acquiring premium parts, paying those costly premiums, may smaller the repair and maintenance expenses.

It is the degree of doing so in terms of a whole system of budget approach that avoids unnecessary pump purchases depending only on here and now considerations by the organization, in other words helps to derive forms of building long-term sellotape on pumps that last.

Innovations in Submersible Pump Technology

Smart Pump Systems

The inclusion of IoT gadgets in the manufacturing and selling of submersible pumps as a product has come a truly substantial development.

Smart pump systems offer the ability to monitor the pump workings and the environment in real-time, providing the capacity to control such parameters as the flow rate, pressure and the energy consumption from a distance.

This advance avails, amongst other things, timely measures to avoid or mitigate any damages which may arise as such issues may be discovered long before these novelties will be able to materialize, thus reducing the time that will be required for the services and their costs.

Superior Materials and Pumps Improvements

With the current technologies in materials combined with chemical properties, submersible pumps that have long-life and are resistant corrosive effects have been produced.

Many industries are gradually using material such as high-quality stainless, composite materials and well as wearing and corrosion inhibiting coating.

These developments made it suitable to operate under extreme conditions such as interacting with harsh chemicals and abrading particulates.

Energy Conservation

In trying to find a way of increasing the rate of developed energy, different methodologies have been experimented in the pumps used under water.

The present day hydraulic pumps are created such that they utilize the advanced hydraulic technologies such as impellers with improved flow paths.

These pumps are very energy efficient and destroy few fossil fuels consequently living the environment in a better state and reducing exploitation of energy resources.

Case Studies and Real-World Applications

Municipal Water Management

In municipal water management, submersible pumps are used for rapid and efficient sewage treatment.

Submersible pumps are often employed by various municipalities in order to combat the challenge of the inability of gravity to allow effluent flow from collection to treatment facilities.

Ability to control the amount of flow and the solid content of the liquid can by all means ensure that the units are functional even when the demand is high.

Agricultural Irrigation Systems

Submersible pumps provide a passive system that allows farmers to utilize water from a well or a reservoir to irrigate their fields.

Upon performing a thorough review in a drought stricken region, it was evident that farmers who put to use submersible pumps marijuana harvesting recorded an exponential rise in the yields attributed to a better watering system as well as better control of the amount of water being used in irrigation.

They are also capable of being submerged in water and combating various levels of water, conditions and problems in agricultural practices of today very well.

Mining Industry Solutions

Groundwater under a mining site often poses more recovery and treatment problems and this has been an accepted issue of the industry.

An example of such a company was one that had to use submersible pumps in dewatering of open-pit mines.

The pumps played a critical role in avoiding potential health hazards associated with flooding which was likely to happen during the rainy period.

This shows that mining activities do not have to stop simply because submersible pumps are known to pump such materials.

Conclusion

Industrial submersible pumps are tools that are required in various sectors since they are capable of offering effectiveness, reliability, and flexibility.

If the conditions and performance of submersible pumps are understood properly, they can help businesses operate more efficiently via smart capital use.

There are benefits to be realized when one invests in a good submersible pump. It is important to undertake research and speak to professionals to ensure that the right pump is selected for your requirements.