Different waterworks applications require submersible pumps as a significant element, which makes water management becomes well-organized for a number of needs.

In this article we will get into the discussion of the various applications of submersible pumps, placing emphasis on the role of submersible pumps in catering for the needs in the field of agriculture, municipal services, elimination of waste water and processing industrial liquids.

Understanding Submersible Pumps

Types of Submersible Pumps

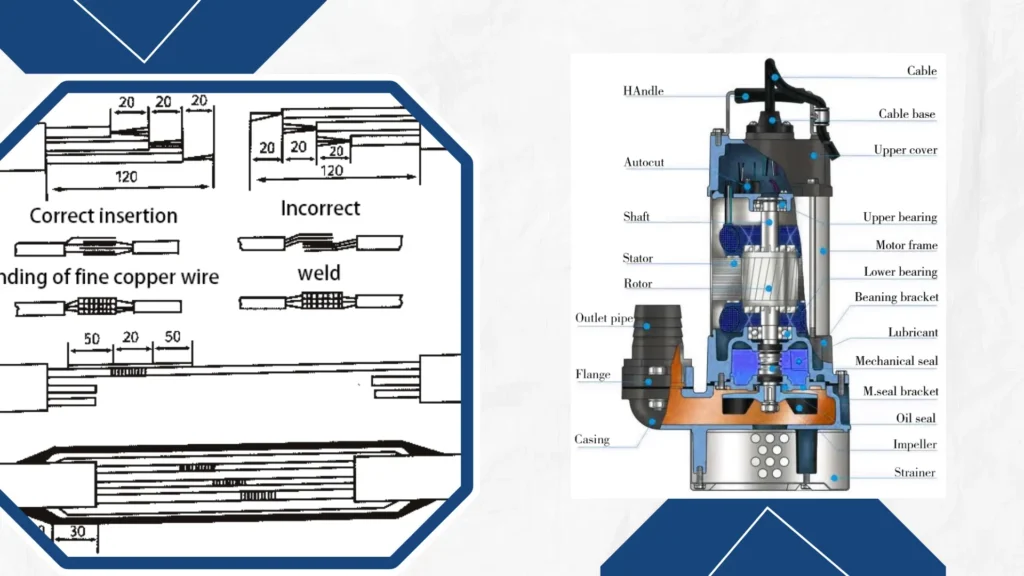

Submersible pumps are pumps that are specifically designed to be operated while basically submerged within fluid.

The remained in water, they don’t draw water from the top like other pumps do but from the source of water directly.

This specialized approach allows it to deliver water to a higher level rather than drawing water to itself, it is better for the user.

For instance, they are mainly for facilitating deep boreholes; constructed for improving drainage systems; industrial requirements.

Modes of Operation

These are types of pumps that change electrical power into kinetic power. Located top of the pump casing is the motor which is integral and operates in a fluid environment.

Therefore the motor together with its associated rotary motion drives the impeller to create the centrifugal force, which helps to transport a given fluid through a single pipeline out of the pump.

In simple sense just like the sea submersible pumps are functional even in considerable depth of application.

Main Attributes

Submersible pumps are characterized by several aspects which help in better performance and an extended life span.

Some of these features include ability to work in ash mining conditions, a range of impellers to work in variety of fluids and protection features to prevent the pump from getting very hot or from getting damaged.

The case of the motor being enclosed is especially significant because it keeps the motor from such exposure ensuring protection and durability.

Applications in Waterworks

Agricultural Irrigation

Learn More:

Overview of Submersible Pumps for Irrigation and Waterworks

In agriculture, especially in irrigation management, submersible pumps are of great importance because they assist in the use of water from wells that are deep or reservoirs hence ensuring the crops are watered.

As a result of such irrigation, farmers get more yields and there food security is improved especially in the dry areas.

Thanks to submersible pumps many farmers manage to use water effectively, cut down on labor costs and improve overall performance.

Municipal Water Supply

The cities use submersible pumps to draw drinking water from the underground aquifers. Without those pumps it would be impossible to provide safe drinking water for the residents all the time.

They are used to move water to the treatment plants or directly to water systems under uniform pressure and flow conditions.

Submersible pumps are efficient in their work in cities because they contribute to containment of public health hazards like provision of safe drinking water and some of the most naive municipal services.

Waste Water Transport

Submerged pumps in sewage treatment systems are used for transporting waste water and sewage water at various stages of treatment.

This type of pumps allows for the pumping of waste with pockets of slush or trash, and is therefore useful in harsh environment applications.

Through smooth transportation of sewage, the submersible pumps contribute to the overall efficiency of the treatment by preventing other forms of impurities and by water pollution.

Industrial Water Supply

For varied services like process water cooling systems, it is typical of industries to rely on submersible pumps.

This is where submersible pumps are essential in maintaining operational effectiveness by providing water on a constant.

Over the years in most industries the efficiency of submersible pumps affects the economy a lot.

Benefits of Using Submersible Pumps

Efficiency and Performance

And More:

Unlocking the Power of High-Performance Submersible Pumps for Effective Water Treatment

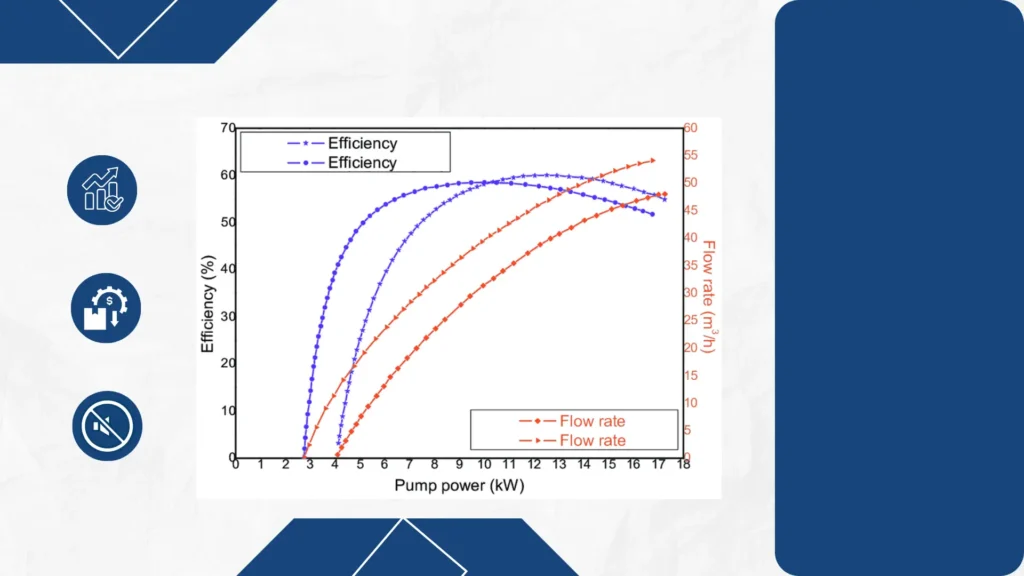

Submersible pumps demonstrate high levels of performance owing to the fact that they are highly efficient pumps in terms of energy consumption.

This level of proficiency in their action also means that they work just as well when they are placed underwater and this leads to reduction of electrical costs and results in impressive performance.

It becomes easy to adopt such pumps for use in many areas right from agricultures to municipals.

Space-Saving Design

Thanks to the reduced size of the submersible pumps it is easy to install them within tight areas such as Water Wells and Construction sites.

The possesses features designed to serve under increased cryogenic duty duties stimulate installation of the submersible medium-duty pumps at a number of basements where a single-station construction or slopes existed.

Businesses and residents are able to optimally use the areas they occupy as well as avoid flooding.

Reduced Noise Pollution

One of the benefits of submersible pumps is that it reduces the noise level as the operation is done under water and thus residential areas are very conducive with such installations.

In these cases, this function helps in achieving the best places by clipping noise exposure, thus offering a calm environment while maintaining its competitiveness.

Selecting the Right Submersible Pump

And More:

Tips for Choosing the Best Submersible Pump for Your Waterworks Needs

Evaluating Your Needs

In contemplating the acquisition of a submersible pump, one must be critical. The amount of water to be dewatered, the level of the ground water and the water quality should be addressed.

These are the factors that you need to be aware of for you to pick the correct pump for your application as that will also ensure effective operation.

Efficiency in Saving Power

When looking for modern products, be wary of environmentally friendly energy-efficient pumps.

There are pump designs that go beyond that and adopt green technology that significantly involves less energy but produces equal or higher output with less power.

Moreover, they are not only beneficial in reducing carbon emissions, but they also come with cost-effectiveness over an extensive period.

Choice of Material

Select pumps and other machineries of the process industry and engineering, made up with the most durable material that the existing technology offers.

Such materials may include but are not restricted to stainless steel or other resistant materials in applications involving corrosive liquids.

Acquiring such a robust machinery enables lesser procurement costs due to less frequency of wear and tear related or other repairs.

Professional Guidance

Seek assistance from the competent and experienced persons in matters of seeking a pump buyer.

Likely, you may have problems selecting a pump type as well as its characteristics due to the available number of pumps and concurs of price limits, this is where advice from a professional can help.

Installation and Maintenance

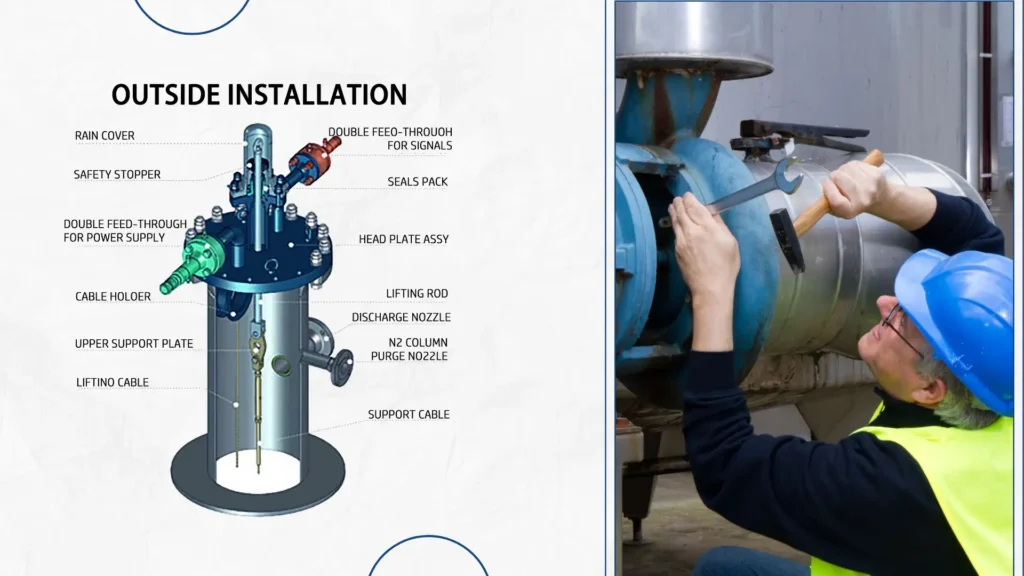

Professional Installation

It is recommended that submersible pumps be installed by a licensed professional to guarantee efficiency and safety in operation.

Installing equipment is necessary in order to maintain the pump in good condition for a long time, prevent various problems related to incorrect assembly in the future.

Importance of Regular Maintenance

It is essential to take care of the pump in order to avoid its breakage in the shortest time possible.

This encompasses everything from keeping an eye on mechanical parts and cleaning filters to checking operation of all elements in place.

It is helpful to have a periodical maintenance plan in place since it will make possible the early recognition of problems avoiding expensive repairs and break

Troubleshooting Common Issues

Knowing the typical problems notably the common tendency of a clog or an electronic issue can lessen operational downtimes.

Make use of the pump manual that groups all the technical ways that the pump operates.

Try to have the help of the technicians incase the facility of the pump cannot be managed.

When to Replace Your Pump

Knowing the symptoms that it is high time to take out the old pump before it is too late is important as it will ensure that no unnecessary repairs are done and save the company funds.

The most common symptoms include drop in pump power, the appearance of strange sounds when the pump is in use or its frequent breakdown.

It is important to note these symptoms sooner rather than later so as to effectively plan for the due replacement.

Cost Considerations

Initial Purchase Costs

Up front expenses to shouldered for the purchase of a submersible pump varies according to its size, type and functionality it is available in.

Conversely you have to remember that substantial part of these costs should be accounted for inside your budget because this will greatly affect the overall cost of your project.

Ongoing Operational Expenses

Some of the operational costs including energy consumption, maintenance and more should be included in the total cost analysis.

Knowledge of these medium-long term operating costs will help in selection and purchasing the ideal pump.

Long-Term Return on Investment

Study the cost benefits over time of having a dependable and efficient submersible pump.

It may seem expensive at first, however, efficient, hard wearing, and low maintenance equipment will help cut expenditure at a crucial period and as such such Auspicious.

Conclusion

Submersible pumps are essential in the numerous waterworks facilities as they offer workability, assurance and adaptability.

Exploring their application in case crop irrigation, civil works, sanitation and industrial use can help decision making by potential customers.

Improvement in water management is a key to many issues in society thereby the purchase of the best quality submersible pump does that.

This is how companies and governments solve the problem of excess water consumption and how is it done without compromising the performance.