In numerous industries, pumps play a vital role in fluid management, and submersible pumps have emerged as a popular choice for their unique capabilities.

However, when considering investment in equipment, potential buyers need to understand the cost – effectiveness of submersible pumps.

This article will analyze how submersible pumps fare in terms of cost and efficiency across different industries, helping businesses make informed decisions about whether these pumps are the right fit for their operations.

Why Are Submersible Pumps Considered for Industrial Use?

Adaptability to Diverse Environments

Submersible pumps are designed to operate while fully submerged in liquids, making them highly adaptable to a wide range of environments.

Whether it’s drawing water from deep wells, handling wastewater in sewage treatment plants, or pumping chemicals in industrial processes, they can function effectively without being affected by the surrounding conditions.

This adaptability reduces the need for complex and costly protective enclosures or additional installation setups.

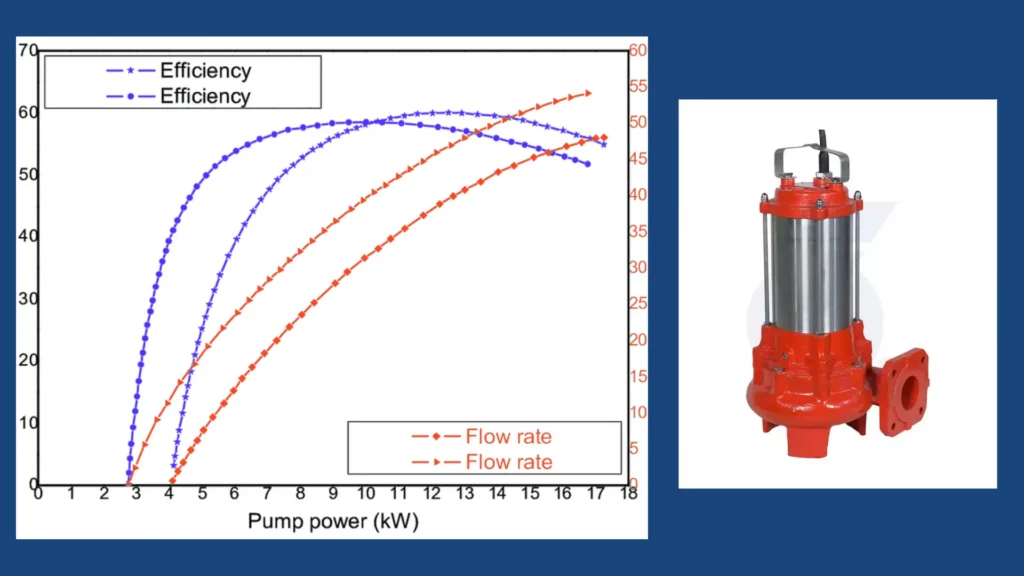

High Efficiency in Fluid Transfer

These pumps are engineered to provide efficient fluid transfer. Their design allows for direct contact with the fluid, minimizing energy loss during the pumping process.

By moving fluids with less wasted energy, submersible pumps can complete tasks more quickly and with lower power consumption compared to some other types of pumps, contributing to overall operational efficiency.

Space – Saving Design

The submersible nature of these pumps means they can be placed directly in the fluid source, eliminating the need for large above – ground installations.

This space – saving design is particularly beneficial in industries where floor space is limited or at a premium, such as in compact manufacturing facilities or urban water treatment plants.

It also simplifies the piping layout, reducing associated installation and maintenance costs.

How Do Submersible Pumps Perform in the Agriculture Industry?

Irrigation Cost – Savings

In agriculture, submersible pumps are commonly used for irrigation. They can draw water from wells or other water sources and distribute it across fields.

Their high efficiency reduces the energy required for water pumping, resulting in significant cost savings on electricity bills.

Their reliability ensures consistent water supply for crops, minimizing the risk of crop losses due to insufficient irrigation and further protecting farmers’ investments.

Low Maintenance Requirements

Submersible pumps in agricultural settings generally have fewer moving parts exposed to the external environment, which leads to lower maintenance needs.

The sealed design protects internal components from dust, dirt, and moisture, reducing the frequency of repairs and replacements.

This not only saves on maintenance costs but also minimizes downtime, allowing farming operations to continue smoothly without interruptions caused by pump failures.

Long – Term Durability

Built to withstand harsh agricultural conditions, submersible pumps offer long – term durability.

They can operate continuously during peak irrigation seasons without significant wear and tear.

Their robust construction ensures they can handle the demands of pumping large volumes of water over extended periods, providing farmers with a reliable pumping solution that offers good value for money over its lifespan.

What Are the Cost – Benefit Aspects in the Construction Industry?

Dewatering Efficiency

In construction projects, submersible pumps are frequently used for dewatering tasks, such as removing water from excavation sites or basements.

Their ability to quickly and effectively remove water helps keep construction sites dry, enabling work to proceed on schedule.

By reducing delays caused by water accumulation, these pumps save on costly project extensions and labor overtime, making them a cost – effective choice for construction dewatering needs.

Versatility in Fluid Handling

Construction sites often deal with various types of fluids, including muddy water, wastewater, and even some chemical – laden liquids. Submersible pumps can handle a wide range of fluid viscosities and impurities.

This versatility means that a single pump can be used for multiple dewatering and fluid – transfer tasks, reducing the need to invest in different types of pumps for different applications and saving on equipment acquisition costs.

Ease of Installation

The installation process for submersible pumps in construction is relatively straightforward.

They can be lowered into the water source using a cable or lifting mechanism, eliminating the need for complex above – ground installations.

This simplicity not only saves on installation time but also reduces labor costs associated with setting up the pumping system, further enhancing their cost – effectiveness in construction projects.

How Do Submersible Pumps Impact the Cost Structure in the Mining Industry?

High – Volume Pumping Capability

Mining operations often require the pumping of large volumes of water, whether it’s for dewatering mineshafts or handling process water.

Submersible pumps are capable of delivering high – volume flow rates, meeting the demanding pumping requirements of the mining industry.

Efficiently handling large amounts of water, they help maintain safe working conditions in mines and ensure continuous operation of mining processes, avoiding costly production halts due to water – related issues.

Resistance to Harsh Conditions

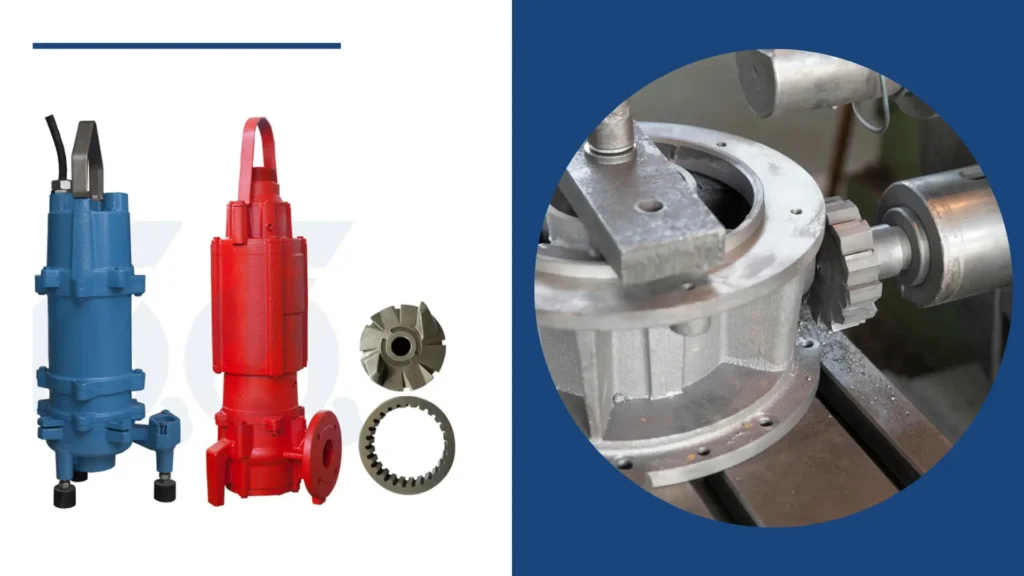

Mining environments are notoriously harsh, with abrasive fluids, high temperatures, and extreme pressures.

Submersible pumps are built with durable materials and robust designs to withstand these challenging conditions.

Their ability to operate reliably in such harsh settings reduces the frequency of breakdowns and replacements, which in turn cuts down on maintenance and equipment replacement costs over the long term, making them a cost – effective option for the mining sector.

Energy – Saving Features

Many modern submersible pumps used in mining come with energy – saving features, such as variable – speed drives.

These features allow the pumps to adjust their speed according to the actual pumping requirements, reducing energy consumption when full capacity is not needed.

Optimizing energy use, mining companies can significantly lower their electricity bills, contributing to overall cost savings in their operations.

What Are the Considerations in the Municipal Water Supply Industry?

Reliable Water Delivery

In municipal water supply systems, ensuring a continuous and reliable supply of clean water is of utmost importance.

Submersible pumps can be installed in wells, reservoirs, or water treatment plants to provide consistent water delivery.

Their reliability minimizes the risk of water shortages or disruptions to the supply, which is crucial for maintaining public services and avoiding costly emergency response measures in case of failures.

Cost – Effective Operation

Submersible pumps in municipal water supply applications offer cost – effective operation.

Their high efficiency reduces energy consumption, resulting in lower electricity costs for pumping water.

Their long lifespan and low maintenance requirements mean that municipalities can spread out the cost of investment over a longer period and spend less on ongoing maintenance, making them a financially viable option for large – scale water supply operations.

Compatibility with Existing Infrastructure

These pumps are generally compatible with existing municipal water supply infrastructure. They can be easily integrated into existing pumping stations, wells, or pipelines without major overhauls.

This compatibility reduces the need for extensive infrastructure upgrades when installing submersible pumps, saving on capital expenditure and ensuring a smooth transition to a more efficient pumping solution.

How Do Submersible Pumps Compare in the Oil and Gas Industry?

Handling Specialized Fluids

In the oil and gas industry, submersible pumps are used to handle a variety of specialized fluids, including crude oil, gas – laden liquids, and produced water.

Their design allows them to operate effectively in high – pressure and high – temperature environments, which are common in oil and gas wells.

Being able to handle these challenging fluids, submersible pumps contribute to the efficient extraction and processing of oil and gas resources, reducing the risk of production losses due to pumping failures.

High – Performance Requirements

The oil and gas industry has high – performance requirements for pumping equipment.

Submersible pumps are engineered to meet these demands, offering high flow rates, high – pressure capabilities, and long – term reliability.

Although the initial investment in submersible pumps for this industry may be higher, their ability to operate continuously and efficiently over extended periods justifies the cost, as downtime in oil and gas operations can result in substantial financial losses.

Technological Advancements

Continuous technological advancements in submersible pump design have led to improved efficiency and performance in the oil and gas sector.

Newer models come with advanced monitoring and control systems that can optimize pump operation, detect potential issues early, and reduce maintenance costs.

These technological features enhance the overall cost – effectiveness of submersible pumps in the oil and gas industry by increasing productivity and minimizing unplanned downtime.

What Are the General Cost Components of Submersible Pumps?

Initial Purchase Cost

The initial purchase cost of submersible pumps varies depending on factors such as size, capacity, material, and brand.

Larger and more powerful pumps with advanced features tend to have a higher upfront cost.

However, it’s important to consider this cost in relation to the pump’s expected performance and lifespan, as a higher – quality pump may offer better long – term value despite the higher initial investment.

Installation and Setup Costs

Installation and setup costs include expenses for labor, piping, electrical connections, and any necessary modifications to the installation site.

While submersible pumps generally have simpler installation processes compared to some other pumps, these costs can still add up, especially in complex industrial settings.

However, their space – saving design often helps offset some of these costs by reducing the need for extensive infrastructure modifications.

Maintenance and Operating Costs

Maintenance costs cover regular inspections, repairs, replacement of parts, and lubrication. Submersible pumps typically have lower maintenance requirements, but these costs can still be a factor over time.

Operating costs mainly consist of electricity consumption, which depends on the pump’s efficiency, the duration of operation, and the volume of fluid being pumped.

Choosing an energy – efficient submersible pump can significantly reduce long – term operating costs.

How Can Businesses Maximize the Cost – Effectiveness of Submersible Pumps?

Proper Pump Selection

Selecting the right submersible pump for the specific application is crucial. Businesses should consider factors such as the type of fluid, required flow rate, head pressure, operating environment, and budget.

Choosing a pump that is appropriately sized and equipped for the task ensures optimal performance and efficiency, avoiding over – or under – sizing that can lead to wasted energy or premature pump failure and increased costs.

Regular Maintenance and Servicing

Implementing a regular maintenance and servicing schedule is essential for maximizing the lifespan and performance of submersible pumps.

Regular inspections can detect potential issues early, allowing for timely repairs and preventing more serious and costly breakdowns.

Proper maintenance also helps ensure that the pump operates at peak efficiency, reducing energy consumption and overall operating costs.

Monitoring and Optimization

Using monitoring systems to track the performance of submersible pumps can provide valuable insights.

These systems can measure parameters such as flow rate, pressure, and energy consumption, enabling businesses to identify inefficiencies and make adjustments.

Optimizing pump operation based on real – time data, companies can further enhance the cost – effectiveness of their submersible pumps and improve overall operational efficiency.

And More:

- Impact of Energy Efficiency on Operational Costs of Submersible Pumps

- Factors Affecting Prices of Submersible Pumps for Waterworks

- Application and Advantages of Different Materials in Submersible Pumps

Conclusion

Submersible pumps offer significant cost – effectiveness across a wide range of industries.

Their adaptability, efficiency, durability, and other features contribute to cost savings in various ways, from reducing energy consumption and maintenance costs to minimizing downtime and ensuring reliable operations.

Whether it’s agriculture, construction, mining, municipal water supply, or the oil and gas industry, submersible pumps have the potential to be a valuable and cost – efficient investment for fluid management needs.