The importance of submersible pumps in various industries is immense. In agri-business, irrigation becomes possible because of the simple extraction of groundwater; these are added ingredients to them.

Dewatering the site is what in fact construction companies do to make the worker feel at ease while building even on a flooded land area.

The rainy season brings the submersible pumps into play because these are commonly used within different municipalities for good storm-water management. Whenever we speak of the above industries, it naturally would not be just the industrial segment but the sectors of other life-meaning, of course, as healthier.

Remaining essential are their uses within the mining operations and oil extraction, where without the movement of fluids to the required area, the mining process and oil extraction would never effectively take place.

Material selection for submersible pump construction plays a significant role in influencing the performance, durability, and cost of the very equipment.

Each material-from stainless steel to thermoplastics and the like-offers unique characteristics that are probably the most effective for various purposes.

For the buyers, it is therefore necessary that they know these materials because only the right material can improve working efficiency by cost savings of maintenance and the extension of the lifespan of the unit.

In this research, we would like to look at some of the most common materials used and their benefits as the material may guide a potential buyer regarding which material should be selected on an information-based decision.

Also Read:

Material Selection for Durable Submersible Pumps in Large-Scale Waterworks

Common Materials Used in Submersible Pumps

Stainless Steel

It is true that stainless steel is resistant to corrosion and one of the strongest materials perfectly suited for submersible pumps.

The stainless steel contains chromium, which is developed as a protective layer above the surface of the metal to prevent rusting and decaying.

Therefore, it is quite perfect for applications like the conveyance of potable water and even very aggressive chemicals.

Such pumps made out of stainless steel find special preference in areas where extreme hygiene is required, as they can be easily cleaned and maintained.

Additionally, they are often more beautiful in appearance than the rest of pumps, and so they make more suitable installations of visible kind.

Cast Iron

This material has been used traditionally for the last 100 years in the industry, which is the basic reason for its popularity.

This is because iron provides the raw material from which cast iron made its positive image, showing durability as well as cost-effectiveness.

Extremely helpful under high-pressure service, it is a common component in heavy, large industrial pumps.

Vibration-absorbing cast iron brings about a reduction in noise with the process of operation.

Though its weight overscores above that of any other materials of which it is composed, still-fashioned construction is always admired by numerous buyers for cost-efficiency and structurally sound plan.

Thermoplastics

Thermoplastics are considered an alternative in the market for constructing submersible pumps in its place of traditional materials.

Along with their weightlessness, they can also be shaped into complex shapes which has been proved advantageous for innovative design works.

Therefore, they also qualify on a high range of resistance against different chemicals, making them beneficial in utilizing during industrial processes involving chemicals and water drilling machine assembling.

It is advantageous in that the material is light and has easy transport and easy installation, thus minimizing the costs of any given project.

Bronze

Corrosion resistance is the key quality of bronze in areas such as marine environment, while it hardly used in slurry and dewatering applications.

Bearing area is only one example in which this property of bronze is ideally demonstrated.

In slurry or dewatering applications, bronze has all required properties; however, bronze is relatively heavy and so is not suitable for most offshore applications.

It offers high wear resistance and efficiency over time due to wear in abrasive conditions.

It also has very good thermal conductivity for effective heat dissipation in high-temperature applications.

Advantages of Stainless Steel in Submersible Pumps

Corrosion Resistance

Stainless steel is considered to be with the maximum capacities in its resistance to corrosion which every engineer will ever need.

Pumps employed in immersible applications and those exposed to chemical aggressions in the environment have become so much useful as it prevents rust and corrosionsmainingodel than other more delicate metals, result, as a consequence, in reduced cost of replacement and reduced lost uptime due to higher useful life.

Durability and Strength

This is the reason why stainless steel is praised as the one with the most power, the one that offers maximum resistance against damage.

It can last very long, retaining its pressure in the presence of hard bumps and heavy knocks.

So enterprises need the right and strong schedule of maintenance as the pumps will be running for continuous 60 hours, abounding worries concerning life hewing or damage.

Heat and Temperature Bearing

Another great property of stainless steel is its ability to resist high temperatures.

This characteristic allows stainless steel pumps to perform well in hot water applications coupled with fluctuating temperatures in the environment.

Moreover, the factor in high temperature tolerance increases the efficiency of the pump as the pump provides consistent performance in very harsh conditions.

And More:

10 Features to Look for in Submersible Pumps

Benefits of Cast Iron in Submersible Pumps

Cost-Effectiveness

Material-wise, cast iron is generally less costly as compared to many other material options, providing an affordable choice for the cost-sensitive buyer to still have a good pump.

Its low entry cost does not, in any way, impinge on its performance; cast-iron pumps can, in general, handle various tasks efficiently.

This cost-effectiveness is the reason for the high demand for cast iron instead of people opting for a high-performance but quite expensive material.

Structural Integrity

Cast iron is strong and inherently provides a well-maintained structural integrity under heavy loads and high pressures.

This applies mainly in greater-scale processes where durability is imperative.

The pump life is increased by endowing cast iron with a proper stress-bearing capability, resulting in fewer replacements.

Vibration Damping Properties

It eliminates avibrinatural vibraitaonnal sources of reinforcement, which considerably improve the performance of submersible propellers.

The reduction of wear and noise during operation generates a quieter and significantly more efficient pumping action.

This property allows ease in vibration-damping which furthers the lifetime of the pump by absorbing less stress on component parts.

Thermoplastics: A Modern Alternative

Light Weight and Versatile

Thermoplastics are visibly lighter than metals, thus they are easier to handle, transport and install.

That really is a very big plus when reduced weight is very critical, as in portable or temporary installations.

They also have the ability to be specialized in certain designs that would fit specific requirements to improved all around functionality of a pump.

Chemical Resistant

They have very good resistance to a wide range of chemicals yet require the attention for applications in the chemical process industry as well as water treatment.

It reduces the chance of corrosion which may extend the life of any pump in the long run, and therefore reduce maintenance costs.

By using thermoplastics, operators can ensure that their pumps remain functional even in harsh chemical environments.

Ease of Fabrication

The availability of thermoplastic allows maximum freedom for the most complicated and tailor-made designs to be put into practice.

This can be converted into optimizing pumps for very specific applications, and subsequently improving performance and efficiency.

As such, project schedules may be shortened due to the quicker manufacturing cycle of thermoplastic components.

The Role of Bronze in Pump Applications

Excellent Resistance to Wear

Bronze has always been a good material for solid particles or abrasive materials with its outstanding resistance to wear: with time the costs for replacement or repair with hardly be necessary owing to the high degree in terms of wear resistance.

Made of bronze, pumps are appropriate for extreme operations in applications: that is why they ensure high reliability for years.

Corrosion Resistance in Saltwater

Being capable of resisting corrosion in salt, bronze is better suited for marine applications.

With it, it can promise that any bronze pump can operate even in tough coastal conditions that other materials could fail to cope.

In the end, considerable savings as well as operation downtimes that the users could have waited for would be avoided by selecting bronze for such purposes.

Good Thermal Conductivity

Brass has the best thermal conductivity, a feature important in most cases due to efficient heat transfer, particularly when regulating temperatures in applications.

In reality, in most cases, a pump typically ends in very good condition as a result of proper maintenance in the aspect of some thermal conductivity.

Through proper selection of materials, the pump either operates at a safe temperature or is extended through the improvement of the life of the parts of the pump: this is done under a condition in which most of the great savings are to take place.

Choosing the Right Material for Your Needs

Consideration Factors

On this account, the selection of a material for a submersible pump calls for greater determinants.

In particular, the type of liquid to be pumped, environmental factors of the location, estimated life span, and all respective health and safety aspects are relevant.

Every material type has its pros and cons, which require particular understanding that will lead the user to opt for the right material type for a particular application.

Application-Specific Variables

Different applications have different overall requirements for selecting materials.

This is exemplified by the fact that in applications where drinking water is supplied, a material must meet specific considerations for being safe and healthy.

With applications in industrial wastewater plants, chemical resistance and longevity are put in the foreground when it comes to the material.

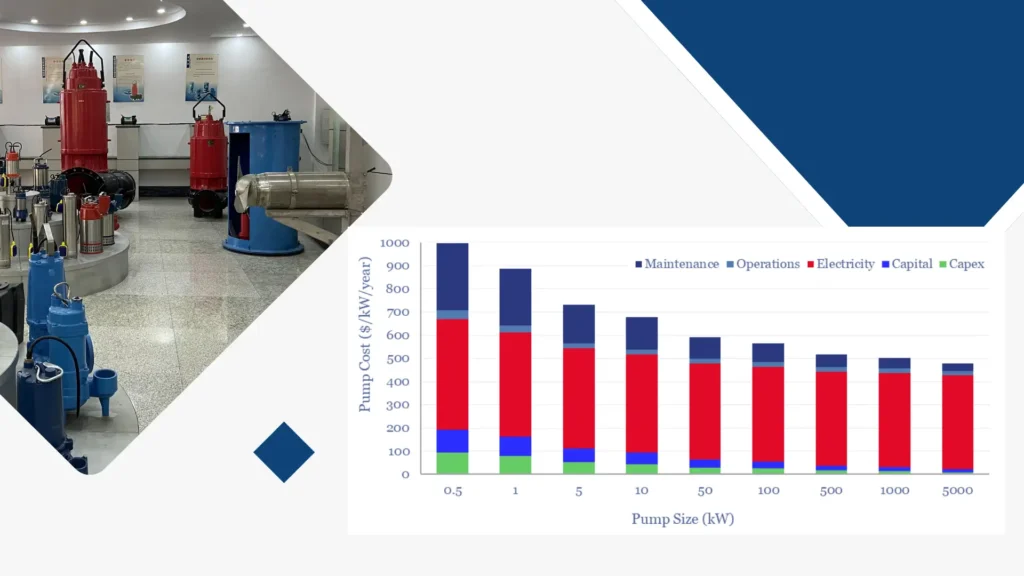

Cost Effectiveness

Choosing a material for a submersible pump will call for striking a balance between cost and performance.

Some may be expensive at the onset of the purchase, but cost-effective in the final analysis due to their good quality and durability, nullifying the cost of frequent maintenance and replacement.

Concerned buyers need to understand their finances as well as the expected performance.

Environmental Impact of Material Choices

Sustainable Materials in Submersible Pumps

Furthermore, as concern for the environment increases, so too does the consideration of the sustainability of materials being used in submersible pumps.

Implications for such circumstances include assessment of the environmental impact of material extraction, production, and disposal, possibly influencing the purchase decision.

Opting for lower environmental footprinted materials for operation has become another means to move towards greater sustainability.

Recycling Opportunities

There are many materials such as stainless steel and bronze that are used within submersible pumps and can perfectly be recycled making the system zero waste.

Fully recyclable materials serve to close the loops and development of plant materials for reuse in other products, promoting sustainability.

Recognition regarding recyclability of available materials by customers would assist them in choosing eco-friendly options that aligned with environmental targets.

Enhancing Long-Term Investment Value

Investing in high-quality, durable material results in long-term benefits as it significantly minimizes the environmental footprints and lifecycle costs.

Choosing materials which go a long distance can save a pump from replacement for a long time, thus reducing resource consumption and waste generated.

Buyers may also come in substantial contribution to the responsible way in commercial industrial operations through consideration to durability and sustainability.

Conclusion

To sum up, the selection of materials for submersible pumps is vital for their performance, durability, and cost-effectiveness.

It can help the purchaser learn about the cardinal material features such as stainless steel, cast iron, thermoplastics, and bronze, making it feasible for him/her to decide the most effective choice for personal purposes.

In this way, by taking into account the requirements for application, differing environmental conditions or limitations on their budget, buyers will opt for the most selection material.

Knowledge of material merits will induce companies to have the enlightened purchasing decision, making for more efficient and effective pump operation.

All we want potential buyers to ponder over is several material options available for submersible pumps.

With this, they can be vigilant not only to satisfactorily meet the current needs of a pump but also achieve extended worth and reliability.

Material understanding and operation can give buyers an idea to invest their money wisely in submersible pump technology.