Submersible pumps are essential tools for managing water in various settings, from residential basements to agricultural fields.

They efficiently remove water, making them invaluable during emergencies like floods.

However, floods can severely impact their performance and longevity, leading to potential failures if not properly addressed.

After a flood, thorough inspection and maintenance of submersible pumps are crucial to ensure they remain functional and safe.

This article provides a comprehensive guide to post-flood pump care, helping you protect your investment and avoid costly repairs.

Why Is Post-Flood Inspection Important for Submersible Pumps?

Assessing Damage

Floods can expose submersible pumps to debris, silt, and contaminants that may cause mechanical or electrical damage.

Debris can block the impeller, while silt can infiltrate internal components, leading to wear and tear.

A thorough inspection helps identify issues before they worsen, allowing for timely repairs and preventing further damage.

Ignoring these initial signs can lead to costly replacements or complete pump failures.

Ensuring Safety

Water damage can compromise the electrical components of a pump, posing safety risks such as short circuits or electric shocks.

A thorough inspection ensures the pump is safe to operate by checking for exposed wiring or corrosion in electrical connections.

This safety assessment is especially critical in emergency situations where electrical hazards can pose significant risks to personnel.

Preventing Future Failures

Identifying and addressing minor issues early can prevent major breakdowns and extend the lifespan of your pump.

Regular inspections allow for proactive maintenance, ensuring that components are functioning optimally.

By catching small problems before they escalate, you can save on repair costs and prolong the operational life of your submersible pump.

Also Read:

- Design and Optimization of Efficient Flood Control Pump Systems

- Choosing the Right Submersible Pump for Waterworks

What Are the Key Steps in Inspecting a Submersible Pump After a Flood?

Visual Inspection

Begin with a visual assessment of the pump. Check for visible damage, such as cracks, dents, or corrosion.

Look closely for signs of debris or sediment buildup that could affect performance.

Pay attention to the pump casing and any mounting components, as structural integrity is vital for overall functionality.

Electrical System Check

Inspect the power cable, connections, and control panel for water damage, fraying, or corrosion.

Ensure all components are dry and functioning properly.

If you notice any signs of moisture, it’s essential to dry these components thoroughly before attempting to operate the pump.

Additionally, check for any burnt or damaged fuses which could indicate electrical issues.

Mechanical Components

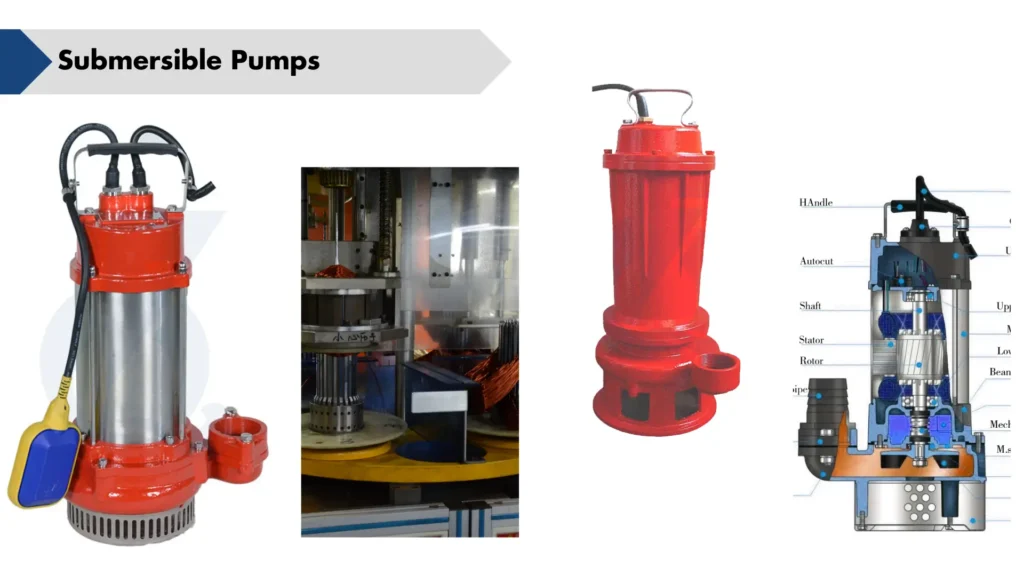

Examine the impeller, seals, and bearings for wear or damage caused by debris or prolonged exposure to water.

The impeller is crucial for moving water effectively, and any damage can lead to reduced performance. Check seals for signs of wear, which can cause leaks and decrease efficiency.

Bearings should be inspected for smooth rotation; any grinding or resistance may indicate wear.

How Should You Clean a Submersible Pump After a Flood?

Removing Debris

Carefully clean the pump to remove mud, silt, and other debris that may have accumulated during the flood.

Use gentle brushes or water jets to avoid damaging sensitive parts.

Ensure that the inlet screens and filters are clear, as blockages can significantly reduce pump efficiency.

Flushing the System

Run clean water through the pump to flush out any remaining contaminants and ensure smooth operation.

Flushing helps remove residual silt and debris that might not be visible during the inspection.

This step is crucial for restoring the pump’s efficiency and preventing future clogs.

Drying the Pump

Allow the pump to dry completely before reassembling or testing it.

Moisture can lead to corrosion or electrical malfunctions if not properly addressed.

Consider using a fan or placing the pump in a well-ventilated area to expedite the drying process.

Ensuring the pump is thoroughly dry minimizes the risk of further damage.

What Maintenance Tasks Should You Perform After a Flood?

Lubricating Moving Parts

Apply appropriate lubricants to bearings, seals, and other moving parts to reduce friction and prevent wear.

Proper lubrication is essential for maintaining smooth operation and extending the life of these components.

Verify that you are using lubricants compatible with the materials in your pump.

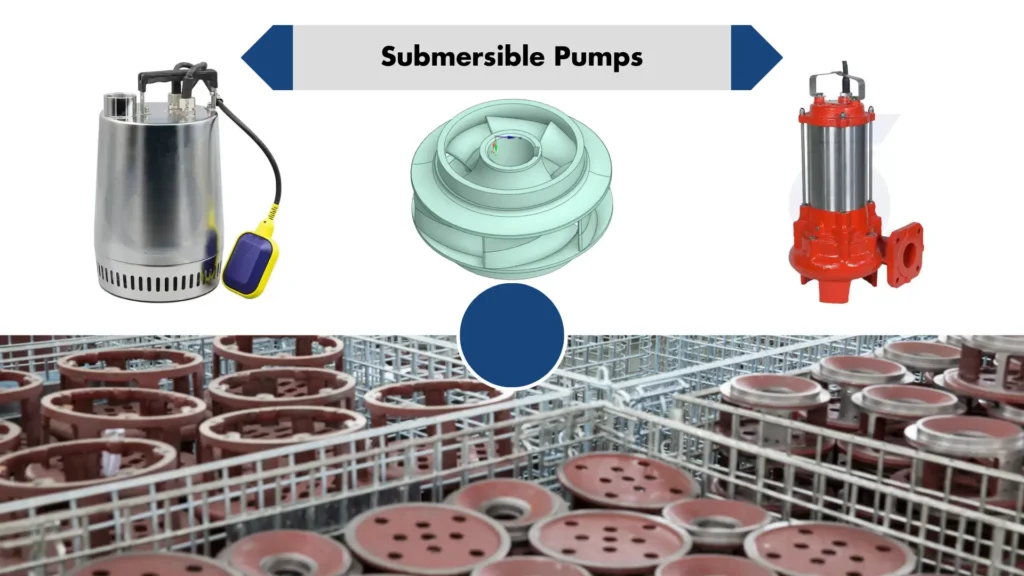

Replacing Worn Components

Replace any damaged or worn parts, such as seals, gaskets, or impellers, to restore the pump’s efficiency and reliability.

Regularly replacing these critical components can prevent performance issues and enhance the pump’s overall functionality.

Testing the Pump

Conduct a test run to ensure the pump operates smoothly and efficiently. Monitor for unusual noises, vibrations, or leaks.

This step is vital for confirming that the maintenance tasks have been effective and that the pump is ready for use. If any issues arise during testing, further inspection may be necessary.

How Can You Protect Your Submersible Pump from Future Floods?

Elevating the Pump

If possible, install the pump on a raised platform to minimize exposure to floodwaters.

Elevation can help prevent the pump from being submerged during minor floods and reduce the risk of water damage, ensuring better protection and reliability.

Using Protective Covers

Invest in waterproof covers or enclosures to shield the pump and its electrical components from water damage.

These protective measures can significantly extend the life of your equipment and reduce maintenance needs after flooding events.

Regular Maintenance

Perform routine inspections and maintenance to keep the pump in optimal condition and reduce the risk of flood-related damage.

Establish a regular maintenance schedule that includes cleaning, lubrication, and component checks, helping to ensure your pump is always ready for use.

What Are the Signs That Your Submersible Pump Needs Professional Repair?

Unusual Noises

Grinding, rattling, or knocking sounds may indicate internal damage or misalignment that requires professional attention.

These noises could signal that components are loose or damaged, which can lead to further issues if not addressed promptly.

Reduced Performance

A noticeable drop in water pressure or flow rate could signal issues with the impeller, motor, or other components.

If the pump is not delivering expected performance levels, it may require professional assessment to diagnose and resolve the underlying problems.

Electrical Problems

Frequent tripping of circuit breakers or inconsistent power supply may point to electrical damage that needs expert repair.

Electrical issues can be complex and potentially dangerous, so seeking professional help is crucial for safety and effective resolution.

How Can You Extend the Lifespan of Your Submersible Pump?

Regular Cleaning

Keep the pump free of debris and sediment to prevent clogs and reduce wear on internal components.

Regular cleaning not only improves performance but also helps identify early signs of wear that may require attention.

Timely Repairs

Address minor issues promptly to avoid more extensive damage and costly repairs down the line.

Ignoring small problems can lead to larger failures, increasing repair costs and downtime.

Proper Storage

If the pump is not in use, store it in a dry, secure location to protect it from environmental damage.

Proper storage conditions help prevent rust and corrosion, ensuring that your pump is ready for use when needed.

What Should You Look for in a Professional Pump Maintenance Service?

Experience and Expertise

Choose a service provider with a proven track record in inspecting and repairing submersible pumps.

Experienced technicians are more likely to accurately diagnose issues and provide effective solutions.

Comprehensive Services

Look for a company that offers a full range of services, from cleaning and maintenance to component replacement and system upgrades.

A one-stop service provider can save you time and ensure consistent quality in maintenance.

Customer Reviews

Check online reviews and testimonials to gauge the reliability and quality of the service provider.

Positive feedback from previous customers can provide confidence in your choice and help ensure you receive quality service.

Conclusion

Post-flood inspection and maintenance are critical to ensuring the longevity and performance of your submersible pump.

By following the steps outlined in this guide, you can identify and address potential issues, protect your pump from future damage, and extend its lifespan.

Whether you handle the maintenance yourself or seek professional assistance, taking proactive measures will save you time, money, and stress in the long run.

Remember, a well-maintained pump is a reliable pump, ready to serve you when you need it most.