Submersible pumps are essential tools in various industries, from agriculture to construction.

They work underwater and play a crucial role in moving liquids efficiently.

Understanding two fundamental concepts—flow rate and head—can help you make informed decisions when selecting a submersible pump for your needs.

This article will break down these terms in a simple, digestible manner to guide potential buyers.

What is flow rate and why is it important for submersible pumps?

Defining Flow Rate

Flow rate refers to the volume of fluid that a pump can move over a specific period, typically measured in gallons per minute (GPM) or liters per second (L/s).

Knowing the flow rate is crucial as it determines how quickly a pump can transfer liquids.

The Role of Flow Rate in Efficiency

Higher flow rates often mean more efficient operations for projects requiring significant liquid movement, such as agricultural irrigation or draining flooded areas.

Understanding the flow rate helps users assess whether a pump meets their project’s demands.

How to Calculate Flow Rate

Calculating flow rate can be straightforward and involves monitoring the volume of water a pump moves over a designated time.

This can be done using simple formulas or flow measurement tools, aiding buyers in selecting the right pump capacity.

Common Applications of Flow Rate

Different industries leverage specific flow rates for optimal results.

For instance, construction sites may require higher flow rates for efficient water removal, while residential applications might need lower rates for garden irrigation.

And More:

- How to Choose the Right Submersible Pump Size Based on Flow and Head

- Key Performance Parameters of Industrial Submersible Pumps

What does “head” mean in the context of submersible pumps?

Defining Head

The term “head” in pumping refers to the height that a pump can raise water, measured in feet or meters.

This measurement depicts the energy or pressure exerted by the pump to lift the water against gravity, reflecting the pump’s capability to overcome vertical distances in various applications.

Understanding this concept is fundamental for anyone looking to install or operate a submersible pump effectively.

Why Head is Critical for Pump Performance

Head measurement is a vital factor that affects a pump’s performance, as it directly influences the pump’s ability to deliver fluid to its intended destination.

It helps users understand the limits of what a pump can achieve, ensuring they choose a model capable of meeting elevation requirements in their projects, ultimately maximizing efficiency and reducing the risk of pump failure.

Without this knowledge, users may end up with a pump that cannot meet their demands.

Types of Head

There are various types of head measurements to consider: static head (height difference between the pump and water source), dynamic head (includes friction losses and other resistances), and total dynamic head (the sum of static and dynamic head).

Knowing these distinctions helps buyers select the appropriate equipment, as they will recognize that not all pumps are created equal in terms of their ability to handle different head requirements.

This understanding aids in making educated choices tailored to specific scenarios.

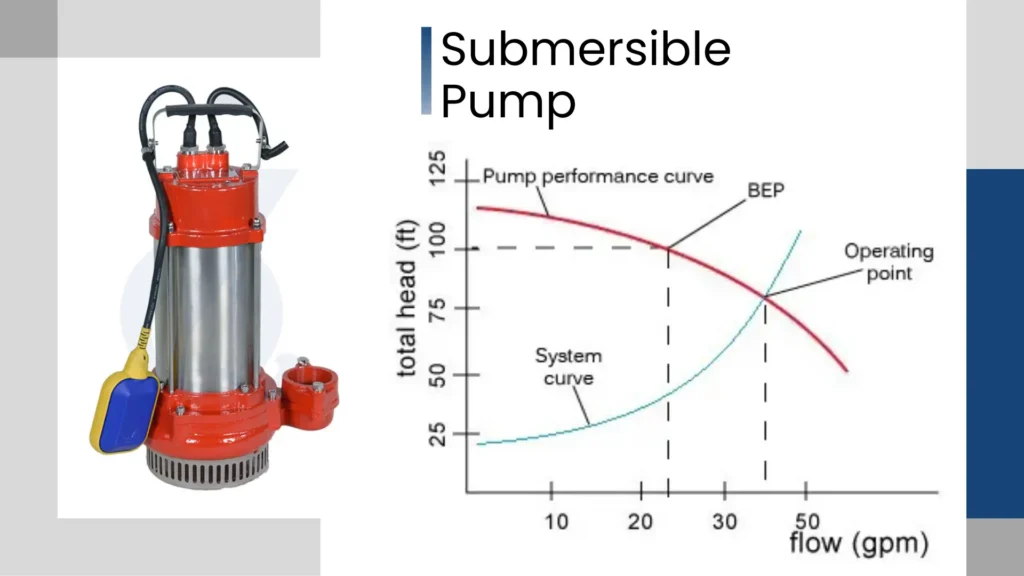

Head in Relation to Flow Rate

It is essential to recognize that flow rate and head are interconnected, meaning that changes in one will affect the other significantly.

A pump’s flow rate typically decreases as the head increases, which implies that customers must consider both parameters when selecting a pump for their operational needs.

Understanding this relationship allows potential buyers to strike a balance between the two for optimal performance, ensuring that they do not compromise one aspect over the other.

How do flow rate and head interact in a submersible pump?

The Pump Curve

Every submersible pump has a pump curve that illustrates the relationship between flow rate and head, serving as a critical tool for pump selection.

This graphical representation helps users visualize how changes in one affect the other, enabling them to make informed purchasing decisions based on real performance data.

By interpreting the pump curve, buyers gain insights into the operational efficiency of the pump under various conditions.

Impact on System Design

When designing a pumping system, understanding the interaction between flow rate and head is vital, as it can dictate the overall effectiveness of the water transfer process.

This knowledge helps in setting up the right piping systems, valves, and storage tanks, ensuring the selected pump performs efficiently without unnecessary energy loss.

Proper system design not only optimizes performance but can also reduce potential maintenance issues over time.

Selecting the Right Pump

By assessing the required flow rate and head for your specific application, you can narrow down your options and select a submersible pump that perfectly fits your needs.

This thoughtful approach prevents the pitfalls of purchasing an underperforming or oversized pump, allowing you to invest in a solution that delivers optimal value.

Additionally, aligning your choice with system requirements can lead to smoother operations and enhanced reliability.

Benefits of Proper Coordination

Coordinating the right flow rate and head maximizes the efficiency of your pump, prolonging its lifespan and decreasing operating costs.

This ultimately leads to significant savings in time and resources, as well as better overall project outcomes.

By prioritizing the harmonious balance between these two parameters, users can ensure that their pumping systems operate at peak performance while minimizing downtime and maintenance efforts.

What factors affect flow rate and head in a submersible pump?

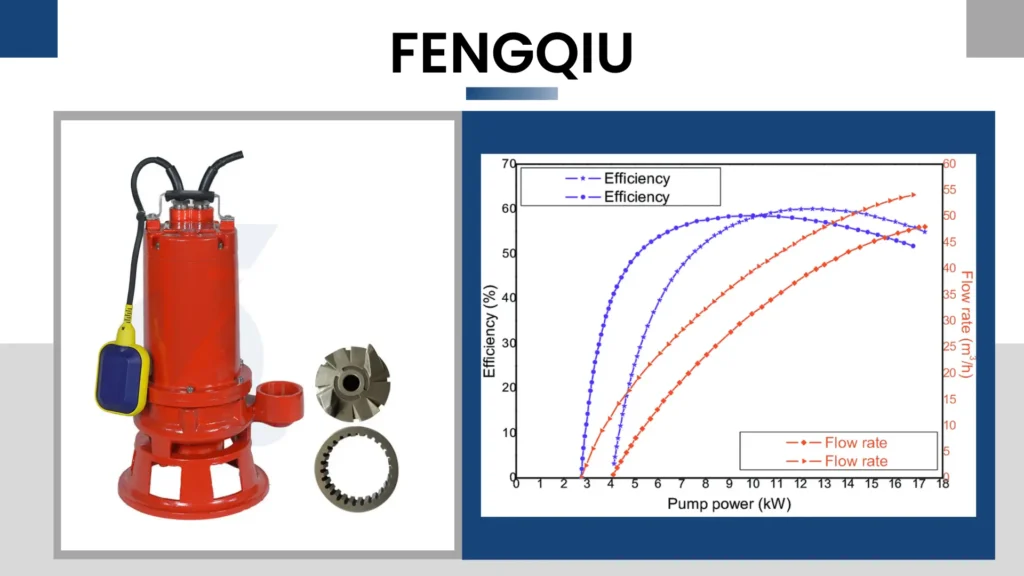

Pump Design and Construction

The materials, design, and construction of the pump directly impact flow rate and head, influencing how effectively and efficiently the pump performs over time.

Higher-quality pumps tend to perform better and last longer, making them a worthwhile investment, while inferior designs may lead to early failures and mediocre performance.

Investing in a well-designed pump can ultimately save both time and money in the long run, as it reduces the likelihood of unexpected breakdowns and maintenance costs.

Fluid Properties

The nature of the liquid being pumped—such as viscosity, temperature, and corrosiveness—can affect how a pump operates and its overall efficiency.

Understanding these properties will guide buyers in selecting pumps designed for specific applications, ensuring they choose a model suited for the particular liquid they intend to handle.

For example, a pump designed for thick, viscous liquids will require different specifications compared to one intended for clean water, so evaluating fluid characteristics is vital to successful operation.

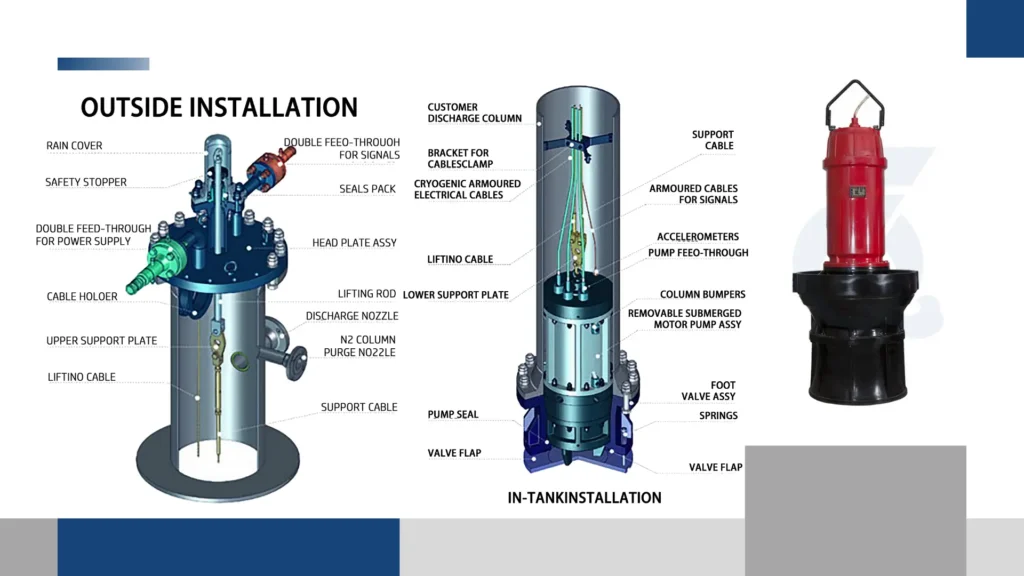

Installation Considerations

Proper installation influences both flow rate and head significantly, as incorrect setup can lead to inefficiencies and operational issues.

Factors such as vertical distance, piping size, and bends in the piping can affect performance, so ensuring proper setup is crucial for optimal operation.

A well-planned installation process not only improves performance but can also minimize wear and tear on the pump, leading to a longer lifespan and reduced maintenance needs.

Maintenance Practices

Regular maintenance and servicing can optimize flow rate and head performance, extending the pump’s life and efficiency in the long term.

A dedicated maintenance schedule allows users to identify and address potential issues before they develop into costly repairs or replacements.

By investing in proper maintenance, operators can ensure their submersible pumps operate at peak performance, avoiding unexpected downtimes that could disrupt operations.

How can I measure the flow rate and head of my submersible pump?

Using Flow Meters

Flow meters can provide accurate measurement of the flow rate in real-time, giving users a clear view of their pump’s performance and efficiency as it operates.

By using flow meters, operators can obtain immediate feedback on how well the pump is functioning, allowing for quick adjustments if necessary.

Implementing flow meters can ultimately enhance reliability and ensure the pump is delivering the expected flow rates.

Measuring Head with Pressure Gauges

Pressure gauges help determine the head by measuring the pressure at the discharge side of the pump, offering valuable insight into the system’s dynamics.

This information allows users to understand the effective pump performance during operation, helping to gauge whether the pump meets its design specifications.

Using pressure gauges effectively can assist in early detection of potential issues, ensuring optimal operations.

Conducting System Tests

Performing system tests, such as a flow test, can offer valuable insights into the actual flow rate and head under working conditions, providing critical data for evaluating performance.

This approach helps validate whether the pump performs as expected in real-world applications and can uncover any discrepancies between anticipated and actual performance.

Such testing is essential for ensuring that the pump is adequately matched to its intended application.

Utilizing Manufacturer Specifications

Most manufacturers provide detailed specifications and performance curves for their pumps that outline expected capabilities under various conditions.

Reviewing these documents can guide buyers in understanding expected flow rates and heads, aiding in making the right choice among available options.

By relying on these specifications, consumers can ensure they make informed decisions that align with their operational needs and constraints.

What should you consider when choosing a submersible pump based on flow rate and head?

Application Requirements

Assessing your specific application needs—whether for agricultural, industrial, or residential purposes—is critical.

Different applications have varying requirements for flow rate and head, influencing the type of pump you should select.

Future Expansion or Changes

Consider future needs or potential changes in your requirements.

If you anticipate needing greater flow rates or head due to expansion, selecting a pump that can accommodate these changes is a wise decision.

Budget Constraints

While investing in high-quality pumps may seem more expensive initially, it often leads to long-term savings due to efficiency and reduced maintenance costs.

Balancing your budget with future performance needs is essential.

Expert Advice

Seeking professional guidance can be immensely beneficial.

Experts can offer insights tailored to your specific situation, helping you choose a pump that balances flow rate and head for optimal performance.

Also Read:

Conclusion

Understanding flow rate and head is crucial for selecting the right submersible pump to meet your needs effectively.

By recognizing their definitions, their interactions, and the factors influencing them, buyers can make informed decisions that lead to efficient performance and long-term satisfaction.

Investing time in understanding these concepts will not only enhance your project’s success but also ensure that you choose a pump that delivers reliable results in the long run.