Quality becomes obviously one of the big factors one could consider in purchasing.

Knowing how to assess the quality of China-made submersible pumps shall be helpful to buyers in making appropriate decisions.

Importance of Quality in Submersible Pumps

Reliability

The reliable pump is designed to run continuously with no failure; thus, it is suitable for an application that requires a continuous and smooth flow of water.

This mostly applies in situations where an interruption would result in big operational problems, such as agricultural irrigation or sewage of a municipality.

A reliable pump ensures that at any given time there is water where it is wanted without an situation of flooding or drought.

Moreover, decent performance by the pumps ensures overall stability in the water management system and the users can comfortably attend to their principal activities without worries of malfunctioning equipment.

Efficiency

An efficient pump will be so designed that it gives maximum performance when using minimum energy.

This not only helps reduce the cost of operation but also minimizes the environmental impact of the pumping process.

The effective pumps handle the job at hand with efficiency and consume less power to operate.

Enterprises and industries dependent upon pumping systems may realize quite a sizeable cost saving by using efficient pumps. In addition, such energy-efficient pumps often have longer lives, hence further reducing replacement and maintenance costs.

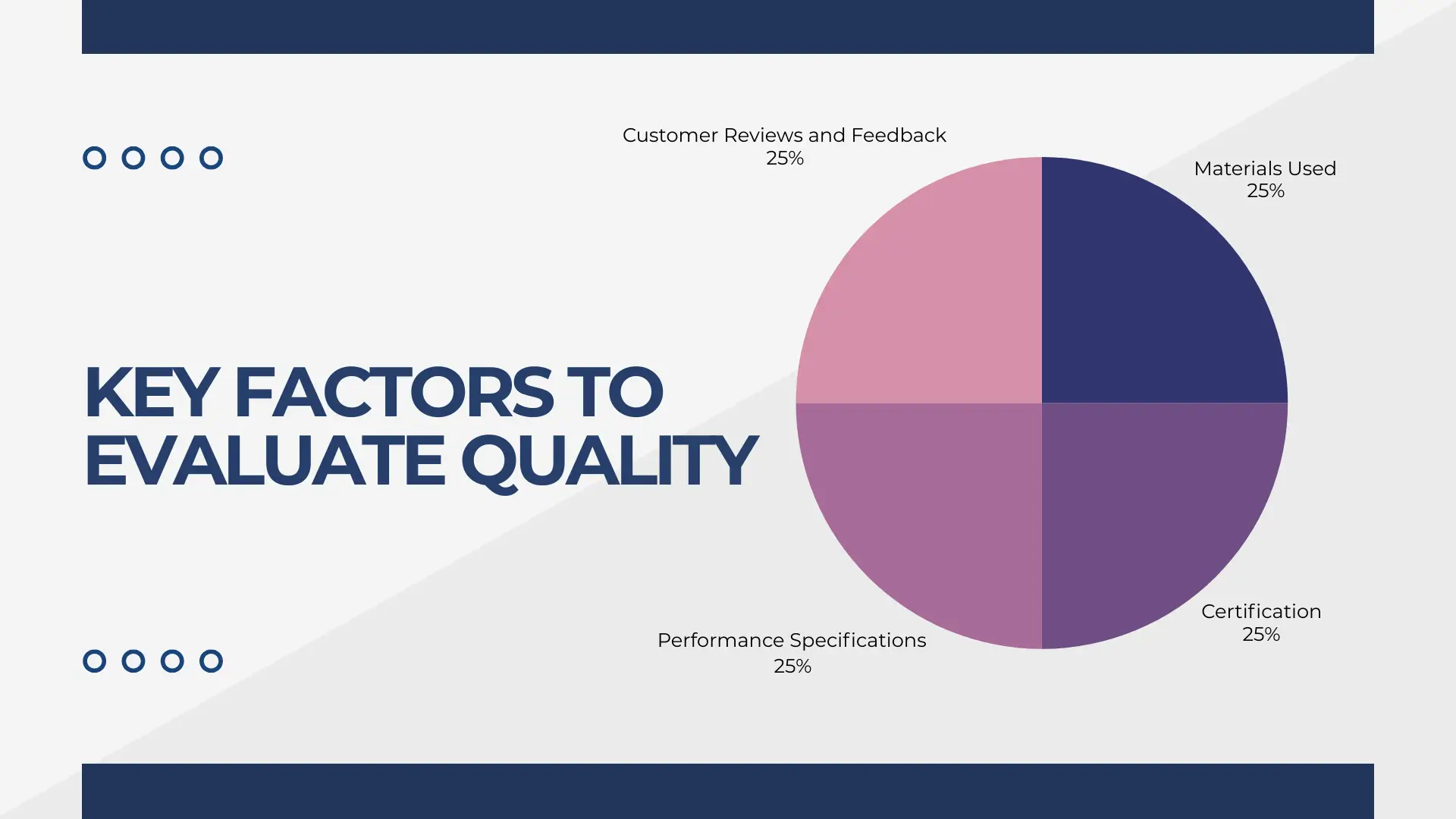

Key Factors to Evaluate Quality

This aspect requires one to pay much attention to a number of factors when evaluating the quality of submersible pumps made in China.

Some key factors relate to materials, certifications, and specifications of performance, among others.

The buyer who pays due attention to these aspects is assured of making informed decisions while investing in reliable and efficient pumps.

Materials Used

High-quality pumps are generally fabricated from construction materials that possess resistance to adverse conditions.

For example, the stainless steel-built pumps have a great level of resistance to corrosion and rusting; hence, they are quite suitable for functioning in water with different chemical compositions.

Similarly, thermoplastic materials show great resistance against wear and tear and are suitable for working in fresh as well as wastewater applications.

These materials are important to look out for when testing a pump, as they directly affect the durability and efficiency of the pump in a real working environment.

Certification

They prove that the product meets certain standards and regulations set by a particular industry.

Look for ISO, CE, or UL:. These certifications indeed mean the pump has been put through the most intense testing and meets international safety and quality benchmarks.

Pumps bearing these certifications have more likelihood of operating in a reliable and safe manner, meaning buyers can have peace of mind as pertains to their investment in them.

Read More:

- Advantages of Buying Submersible Pumps from China

- How to Choose High-Efficiency Submersible Pumps

- The Advantages of Submersible Pumps Manufacturer in China

Performance Specifications

Being able to view a submersible pump’s performance specifications is crucial to being sure it will meet your specific needs.

1. Flow Rate

This reflects the amount of water a pump can move within a given time. The bigger the flow rate the larger the volume it can handle, and hence it is suitable for high demanding applications.

2. Head Height

It refers to the height a pump can raise up water effectively. The head height has to be well understood in those applications that may involve the movement of water over long distances or large heights.

3. Power Consumption

They save on energy costs since their pumps are far more efficient. Check for specifications that provide information about its power consumption, which ought to be lower than others for the same performance.

Customer Reviews and Feedback

Look out for feedback regarding vital aspects like durability, efficiency, and ease of use.

Positive reviews from verified users can act as an assurance in itself that the product is trustable and works.

Also, notice repeating complaints in negative reviews as that may point towards design or functional flow in the pump.

The customers’ reviews can give you a far better insight into any product before purchasing it.

Testing and Quality Assurance

Quality Control Processes

During manufacturing, the pumps are tested for various conditions that they would face while in operation.

These may include tests for flow rate, pressure, energy consumption among others.

The string tests ascertain that no pumps go to market if their performance is below the specified criteria.

Additional checks during different stages of production can observe such defects with sufficient time left, therefore preventing defective products from reaching the customers.

Third-Party Testing

These are independent agencies that take on the testing of quality and performance of the pumps.

By outsourcing this testing, the manufacturer has ensured that thorough and tested assessment of his products is carried out by relevant experts who are isolated from the production lines.

This adds a level of extra credibility to the quality assurance measures. When seeking a maker, one is good asking them what third-party testing they have passed.

In some cases, accreditation by recognized testing bodies can be an indicator of the reliability and adherence to industry standards of a pump.

Conclusion

The quality check of the submersible pumps from China is, therefore, significant if the investment in machinery has to be wise.

The searches for reliable and efficient pumps are considered in materials, their certifications, performance record, and customers’ comments.

The quality of a pump satisfies not only needs for its operation but also provides peace of mind.

Careful assessment will enable the customers to choose rightly among these submersible pumps for appropriate applications.