Submersible pumps are finding their applications in various industries and commercial areas.

Understanding the inner mechanism and advantages of these pumps will help a business enterprise reach a decision whether to purchase one or not.

Here is a detailed explanation of submersible pumps, their applications, and factors to consider if one is a potential buyer.

What Are Submersible Pumps?

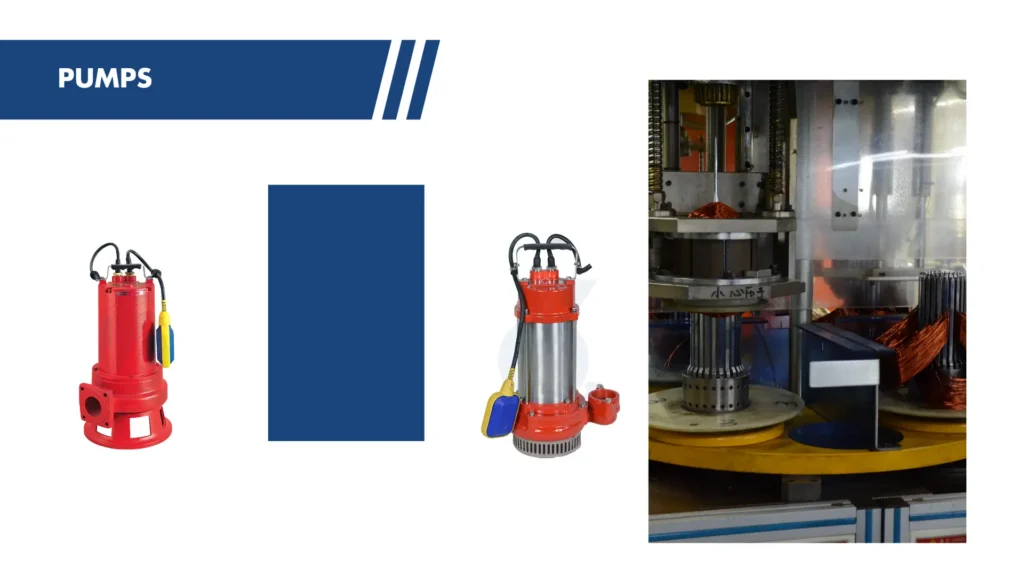

Submersible pumps are a special class of pumps that work wholly under water.

Whereas conventional pumps always rely on suction to draw water from the surface, submersible pumps are plunged into the liquid they will pump out; hence, the ability to push water up to the surface rather than pulling it.

Such a unique configuration increases not only their efficiency but also considerably lowers the risk of cavitation-a phenomenon that could actually damage pumps if the pressure becomes too low.

The submersible design protects the motor and pump components from water intrusion for reliable operation in demanding environments.

Key Features

Sealed Design

One of the distinguishing features that makes submersible pumps is their sealed nature.

In essence, water cannot penetrate into the motor, which also plays a vital function in maintaining the longevity of the pump.

It keeps internal components dry, minimizing corrosion and electrical failures that will extend the life of the pump.

High Efficiency

In simple terms, they can comfortably handle different scenarios, from high flow rates to pressure.

This makes the application of such pumps wide and varied, making them ideal for diverse situations.

This form of efficiency not only adds to improved performance but also results in lower energy consumption, which is a key advantage in business due to cost savings accrued from such areas.

The diversity with which the application occurs enables their use in various operations and different industries and applications.

Versatility

In a wide use such as drainage, sewage management, irrigation of crops, among others, submersible pumps will ease through different environments and different tasks.

Submersible pumps can serve even in the most risky conditions, hence preferred across different industries.

Applications of Submersible Pumps

Water Supply and Distribution

Some of the most important water supply chains depend on submersible pumps playing a very vital role.

These submersible pumps transport the water very efficiently from wells or reservoirs to treatment facilities for purification, ready to be distributed.

This capability is extremely important in both municipal and industrial uses with respect to ensuring that both the community and business sectors get enough clean water.

Wastewater Management

The most crucial use of submersible pumps is in sewage treatment plants for waste and sludge transfer.

They pump the sludge along the course of the waste treatment procedure, which helps to keep the environment clean and free from bacteria.

Handling wastewater efficiently means these pumps play an important role in public health and environmental protection.

Agriculture

These in turn enable the crops to receive a good amount of water supply especially for those areas with low levels of water.

The capabilities mentioned herein are vital in respect to agricultural productivity and maintenance of food supply.

Construction

Groundwater regulation is the most common requirement in the majority of the construction projects.

Dewatering simply refers to the process of getting rid of unwanted water at the work sites to maintain it as dry and safe as possible.

This will prevent delays and further sustains on-site construction activities to make sure timely completion of any project.

Read More:

- Advantages of Buying Submersible Pumps from China

- Types and Applications of Submersible Pumps in Agriculture

- Understanding Residential and Municipal Submersible Pumps

Advantages of Submersible Pumps

Space-Saving Design

Because the installation of submersible pumps is underwater, they occupy less surface area compared to other conventional pumps.

This may be extremely useful in areas without much real estate to boast of.

In such cases, it would be able to allow businesses to fit operational layouts into smaller spaces without loss of efficiency or output.

Noise Levels are Muffled

They can operate without causing disturbances to the communities that surround them by muffling any loud noise resulting from their functioning process.

Their operational principle therefore makes them very suitable for usage in urban areas where noise pollution has to be put into consideration.

Lower Energy Costs

Tend to be most energy-efficient, running at higher capacities compared to those mounted on the surface.

The less energy used, the cheaper it is regarding operational costs in the long run.

It is not only effective for the bottom line but also when it comes to sustainability since less energy will be utilized.

Low Maintenance

This obviously means that in this type of pump, the actual amount of required maintenance is much lower.

It lessens the cases of time lag as well as costs connected with repairing and replacing.

In this way, it enables a business to pay attention to its core operations and stay away from continuous headaches related to incidents of failure of a pump.

Key Considerations When Purchasing

Pump Capacity

A capacity-satisfying pump should be selected so that operations may proceed harmoniously and with ease.

It would be prudent to get a pump whose operational capacity will adequately cater to the peak demand without overstretching its capacity.

Head Height

Another critical factor affecting pump performance is the head height, basically referring to the distance the pump needs to lift the liquid.

Getting the head height correct will help in the selection of a pump that operates efficiently under your given conditions for the best performance possible.

Material and Construction

The materials of construction of the pump must be suitable for the liquid being pumped.

If it is an acid or has abrasive particles in it, a robust material-made pump needs to be selected to bear such a liquid.

Power Source

Determine how much electric or gas power you have available for your operation.

Your choice of a pump may be dictated by what infrastructure is already in place to avoid extra costs and complications at installation.

Reputation of Manufacturer

A pump from a good, reputable manufacturer is important for consideration of assurance of quality and reliability.

Researching customer reviews and warranty options may lead to valuable insight about how the pump performs, the degree a manufacturer will stand behind it, and may help inform your decision in a more grounded way.

Conclusion

Submersible pumps serve many industries efficiently, reliably, and adaptively.

By studying the applications and advantages of submersible pumps, potential buyers will be able to construct effective solutions for better enterprise operations.

Investing in the right submersible pumps can bring considerable long-term benefits in water supply, wastewater management, agriculture, and construction, eventually fostering business growth and sustainability.