Product features

- The flow passage component adopts the unique design method , with wide high-efficiency area , and full-lift ( no overload ) performance .The pump is able to be effectively and safely operated in a larger flow range.

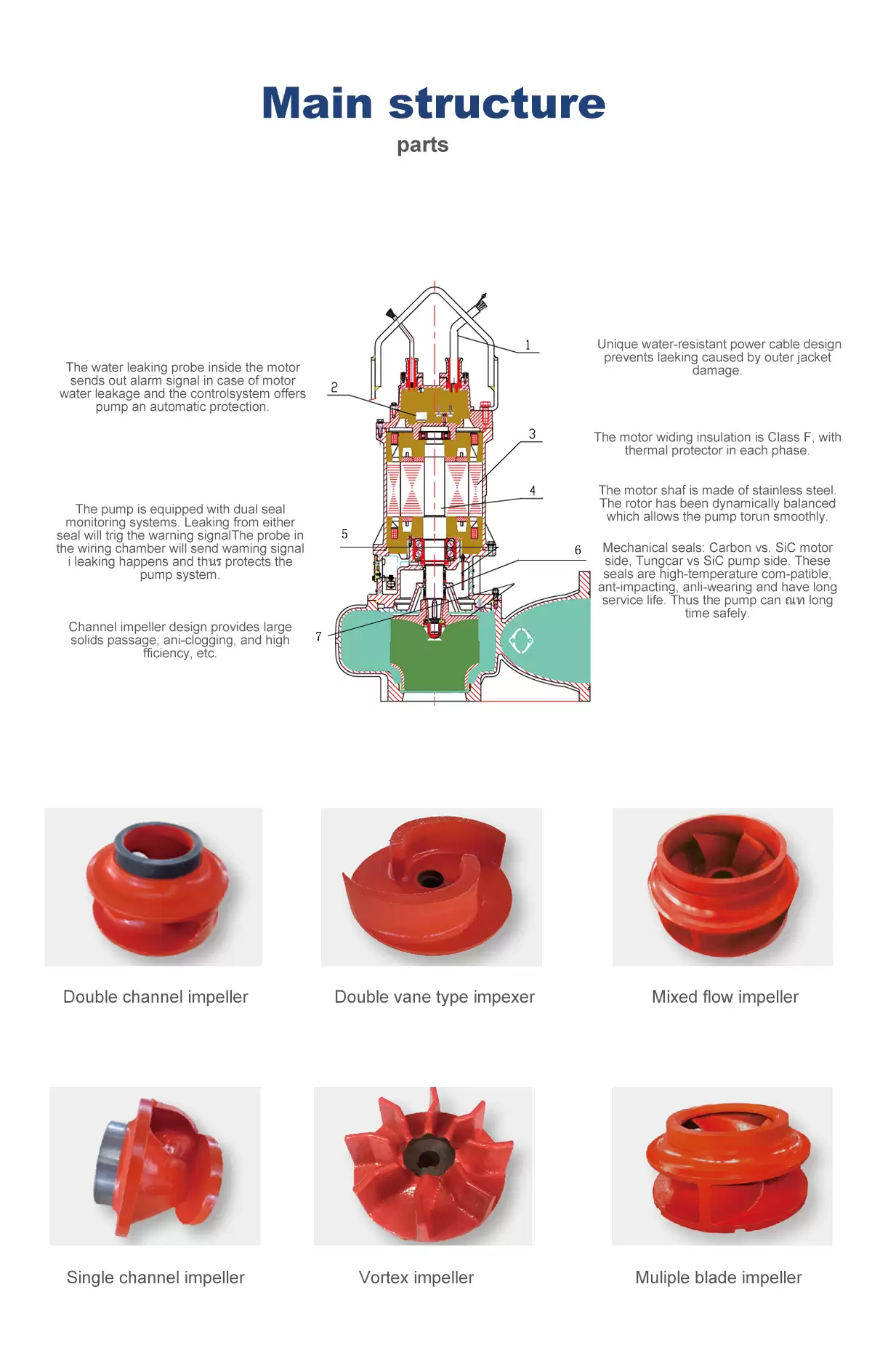

- Strong carrying capacity and large-channel clog-proof design of impellers can make the pump effectively deliver the liquid containing solid particles , impurities and microfiber with the diameter of 6-125 mm.

- The motor uses the sleeve-type external circulation cooling system , which means that the product may be reliably operated when it is above the liquid level or the dry-type installation is adopted

- The product is equipped with alarm protection systems for water leakage , electric leakage , oil leakage , overload , voltage shortage and phase loss , as well as liquid level control systems , able to carry out the centralizedcontrol and effective protection for various operating states.

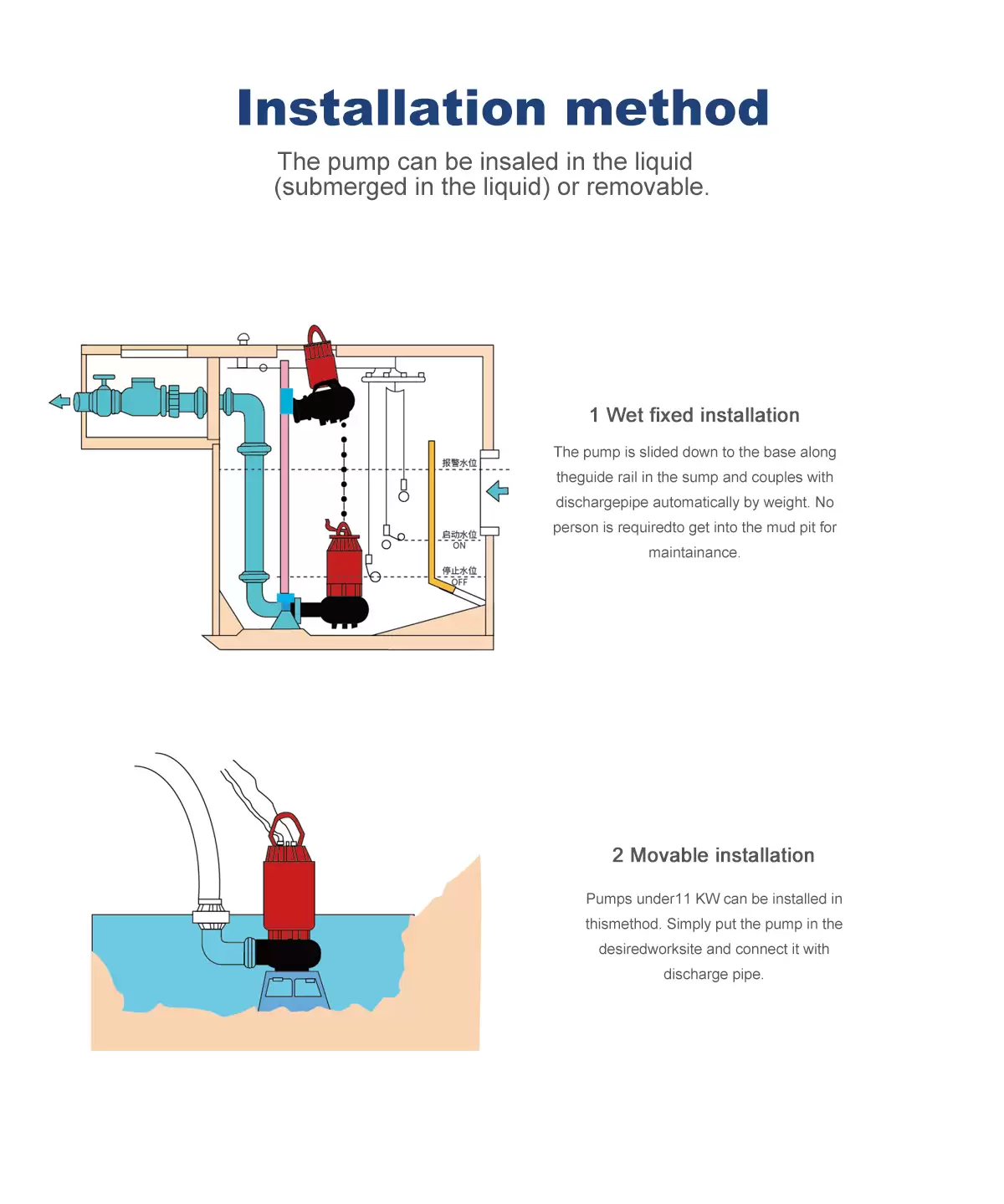

- The automatic installation system is reasonable in design , with high intensity flexible and convenient installation , and no need of states constructing pump rooms so as to save the project cost.

- Adopt the imported high-quality bearing and grease with high temperature resistance , so that the quick-wear parts service life is more than 10,000 hours.

Specifications

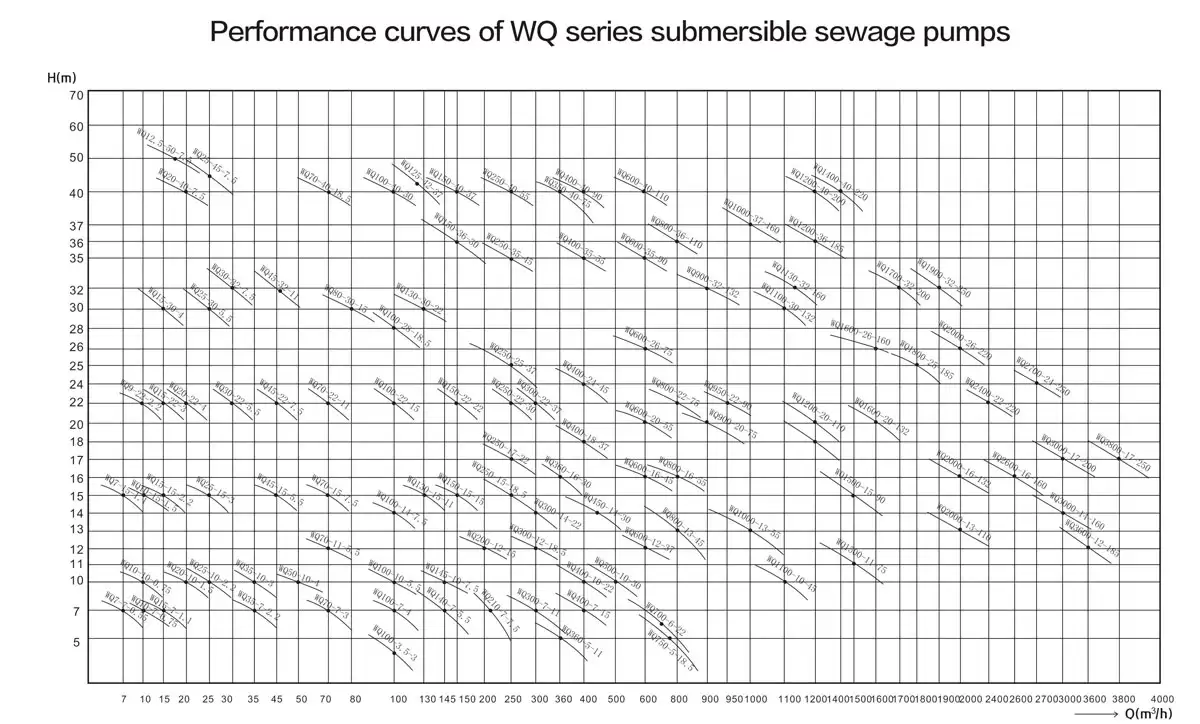

- Power : 0 . 55~315KW

- Flow : 7~4600m³ / h

- Outlet Diameter : 50-600mm

- Head : 4 . 5~50m

APPLICATION FIELDS

- It is mainly used far removing various sewagesludges in municipal and industrial sewage treatment projects, industrial and mining enterprises, hospitals, hotels, restaurants, construction and other industries. It is used for transporting urban sewage, wastewater and rainwater containing solid particles and various fibers. It is also used for farmland irrigation.

OPERATING CONDITIONS

- Medium temperature not exceed40℃,medium density not exceed1.2kg/dm3,solid contents less than 2%.

- Liquid PH value is between 4 and 10.

- Pump motor can not operate above liquid level.

BEFORE OPERATION. READ THE FOLLOWING INSTRUCTIONS CAREFULLY

- Checkwhether the pump was crushed. damaged, or fasteners are loosing or dropped Off due to shipping & handling or in storage.

- Check the oil level inthe oil chamber.

- Check whether the impeller can rotate easily.

- Check whether the power supply is safe.reliable and works normally.The voltage and frequency should meet the requirement(380V+/-5%,Frequency 50 HZ+/-1%).

- Check cable, connector box and cable inlet seal. Make correctionsimmediately when electricity Leakage is found.

- Do not lift pump with cable to avoid accident.

- Check motor insulation to ground with 500 V mega meter. The resistance must bemore than or equalto2 MΩ. If not, tear down the pump and check the pump is securely grounded.

- The pump is not supposed to work in flammable or explosive environment, nor should itbe used to pump erosive or flammable liquids.

- Check pump direction. It should runcounter-clockwiseif viewfrom inlet side.Exchange any two wiresinside the cable if the pump runs in reverse direction.

- After using for one year, it is recommended that pump be examined and repaired, and the oil in oil chamber, mechanical seal, bearing lubricant and other vulnerable parts be replaced so that the pumping system can work properly when needed.It is not necessary to replacegrease in bearing if the beatingis still Within its service life.

- The seal ring between the impeller and casing performs sealing function. To keep the pump’s efficiency.,the seal ring should be replaced when the gap betweenthe impeller and the ring is over 2.0 mm because of worn out.

- Lift out he pump from liquid ifthepump won’t be used for long time to avoid moisture getting insidethemotor housing and thus extendthepump life.When temperature is toolow, lift pump out of liquid to avoid pump from being frozen.

- Handle pump carefully duringmoving and installation.

- Pump can be worn out quickly if running in liquidwith too much sand slurries.

Read following records far solutions troubleshooting pumps. It will save your time.

| FAULT SYMPTOM | POSSIBLE CAUSES | SOLUTION |

| Np pumping or low flow. | Pump run invert. | Adjust rotating direction. |

| Pipe or impeller may be jammed. | Remove debris. | |

| Motor does not run or runs too slow | Check power voltage and current. | |

| Water level is too slow or valve is closed. | Adjust water level and check valve | |

| Seal ring may be worn out. | Replace seal ring. | |

| High density or high viscosity of liquid. | Change liquid | |

| Unstable operation. | Rotor or impeller not balanced. | Return pump to service center for adjustment or replacement. |

| Bearing worn out. | Replace bearing. | |

| Low insulation resistanceofpump system overload. | Power cable damaged or leaking form the cord connection. | Replace and tighten the jam nut. |

| Power voltage too low or power cord size too small. | Adjust power voltage or replace power cord. | |

| Mechanical seal worn out | Replace mechanical seal. | |

| “O”seal ring damaged. | Replace“O”seal ring | |

| Pump runs in high flow and low head range. | Adjust the pump working point to its rated. |

Product Parameters

| No. | Model | Discharge (mm) |

Capacity (m³/h) |

Head (m) |

Power (KW) |

Speed (r/min) |

Efficiency (%) |

Voltage (V) |

Current (A) |

Solid Handling (mm) |

Weight (kg) |

| 1 | 50WQ9-22-2.2 | 50 | 9 | 22 | 2.2 | 2860 | 44 | 380 | 4.8 | 25 | 45 |

| 2 | 50WQ15-30-4 | 50 | 15 | 30 | 4 | 46 | 8.6 | 25 | 70 | ||

| 3 | 100WQ100-10-5.5 | 100 | 100 | 10 | 5.5 | 1460 | 61 | 12.2 | 35 | 140 | |

| 4 | 150WQ145-10-7.5 | 150 | 145 | 10 | 7.5 | 74 | 16.6 | 85 | 195 | ||

| 5 | 80WQ45-32-11 | 80 | 45 | 32 | 11 | 56 | 24 | 30 | 250 | ||

| 6 | 150WQ200-12-15 | 150 | 200 | 12 | 15 | 75 | 32 | 50 | 300 | ||

| 7 | 200WQ300-12-18.5 | 200 | 300 | 12 | 18.5 | 73 | 38 | 75 | 420 | ||

| 8 | 150WQ150-22-22 | 150 | 150 | 22 | 22 | 71 | 45 | 50 | 400 | ||

| 9 | 250WQ500-13-30 | 250 | 500 | 13 | 30 | 980 | 80 | 61 | 125 | 800 | |

| 10 | 150WQ150-40-37 | 150 | 150 | 40 | 37 | 1460 | 67 | 70 | 45 | 680 | |

| 11 | 250WQ600-20-55 | 250 | 600 | 20 | 55 | 980 | 75 | 104 | 125 | 920 | |

| 12 | 200WQ350-40-75 | 200 | 350 | 40 | 75 | 70 | 141 | 55 | 1500 | ||

| 13 | 250WQ600-35-90 | 250 | 600 | 35 | 90 | 75 | 168 | 125 | 1750 | ||

| 14 | 350WQ1000-28-132 | 350 | 1000 | 28 | 132 | 79 | 260 | 125 | 2200 | ||

| 15 | 500WQ3000-28-315 | 500 | 3000 | 28 | 315 | 740 | 82 | 560 | 125 | 5000 |

Dimensions

| No. | Type | DN | ø B | ø C | H | H1 | H2 | H3 | T | T1 | T2 | P | H4 | M | F | gl | g2 | e | n2–d | n1–k | El X E2 |

| 1 | 50WQ9-22-2.2 | 65 | 145 | 180 | 551 | 250 | 100 | 500 | 260 | 180 | 110 | 12 | 198 | 195 | 40 | 180 | 180 | 260 | 4 – ø18 | 4 – ø20 | 700 X 600 |

| 2 | 50WQ15-30-4 | 65 | 145 | 180 | 800 | 250 | 100 | 500 | 280 | 180 | 110 | 12 | 198 | 195 | 40 | 180 | 180 | 260 | 4 – ø18 | 4 – ø20 | 700 X 600 |

| 3 | 100WQ100-10-5.5 | 100 | 180 | 229 | 1050 | 395 | 200 | 800 | 380 | 260 | 110 | 12 | 305 | 195 | 50 | 240 | 240 | 340 | 8 – ø18 | 4 – ø20 | 800 X 600 |

| 4 | 150WQ145-10-7.5 | 150 | 240 | 280 | 1065 | 450 | 100 | 800 | 440 | 260 | 110 | 12 | 385 | 195 | 50 | 240 | 300 | 340 | 8 – ø23 | 4 – ø27 | 900 X 700 |

| 5 | 80WQ45-32-11 | 100 | 180 | 229 | 1200 | 395 | 100 | 850 | 440 | 260 | 110 | 12 | 305 | 195 | 50 | 240 | 240 | 340 | 8 – ø18 | 4 – ø20 | 850 X 600 |

| 6 | 150WQ200-12-15 | 150 | 240 | 280 | 1230 | 450 | 100 | 900 | 440 | 260 | 110 | 12 | 385 | 200 | 50 | 240 | 300 | 340 | 8 – ø23 | 4 – ø27 | 900 X 700 |

| 7 | 200WQ300-12-18.5 | 200 | 295 | 335 | 1301 | 615 | 150 | 1000 | 532 | 268 | 120 | 14 | 500 | 280 | 152 | 520 | 520 | 480 | 8 – ø23 | 4 – ø35 | 1100 X 800 |

| 8 | 150WQ150-22-22 | 150 | 240 | 280 | 1329 | 450 | 150 | 950 | 500 | 260 | 110 | 12 | 385 | 200 | 50 | 240 | 300 | 340 | 8 – ø23 | 4 – ø27 | 1000 X 700 |

| 9 | 250WQ500-13-30 | 250 | 350 | 390 | 1689 | 720 | 300 | 620 | 702 | 423 | 140 | 14 | 545 | 280 | 185 | 700 | 700 | 650 | 12 – ø23 | 4 – ø40 | 1400 X 900 |

| 10 | 150WQ150-40-37 | 150 | 240 | 280 | 1538 | 450 | 150 | 100 | 530 | 260 | 110 | 12 | 385 | 200 | 50 | 240 | 300 | 340 | 8 – ø23 | 4 – ø27 | 1200 X 800 |

| 11 | 250WQ600-20-55 | 250 | 350 | 390 | 1738 | 720 | 300 | 1200 | 702 | 423 | 140 | 14 | 545 | 280 | 185 | 700 | 700 | 650 | 12 – ø23 | 4 – ø40 | 1400 X 1000 |

| 12 | 200WQ350-40-75 | 200 | 295 | 335 | 2194 | 615 | 200 | 680 | 770 | 268 | 120 | 14 | 500 | 280 | 152 | 520 | 520 | 480 | 8 – ø23 | 4 – ø35 | 1650X1200 |

| 13 | 250WQ600-35-90 | 250 | 350 | 390 | 2250 | 720 | 300 | 680 | 742 | 423 | 140 | 14 | 545 | 280 | 185 | 700 | 700 | 650 | 12 – ø23 | 4 – ø40 | 1500X1100 |

| 14 | 350WQ1000-28-132 | 350 | 460 | 500 | 2270 | 750 | 400 | 700 | 882 | 431 | 140 | 14 | 585 | 280 | 250 | 780 | 780 | 770 | 16 – ø23 | 4 – ø40 | 1650 X 1350 |

| 15 | 500WQ3000-28-315 | 500 | 620 | 670 | 2790 | 970 | 400 | 900 | 1230 | 650 | 140 | 14 | 775 | 280 | 105 | 780 | 780 | 900 | 20 –ø26 | 6 – ø40 | 2300 X 1900 |